Solar 'finned heat pipe'

A fin type, solar energy technology, applied in the field of solar energy application, can solve the problems of low actual thermal efficiency, insufficient hot water supply, and fewer users, and achieve the effects of excellent heat collection performance, easy mass production, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

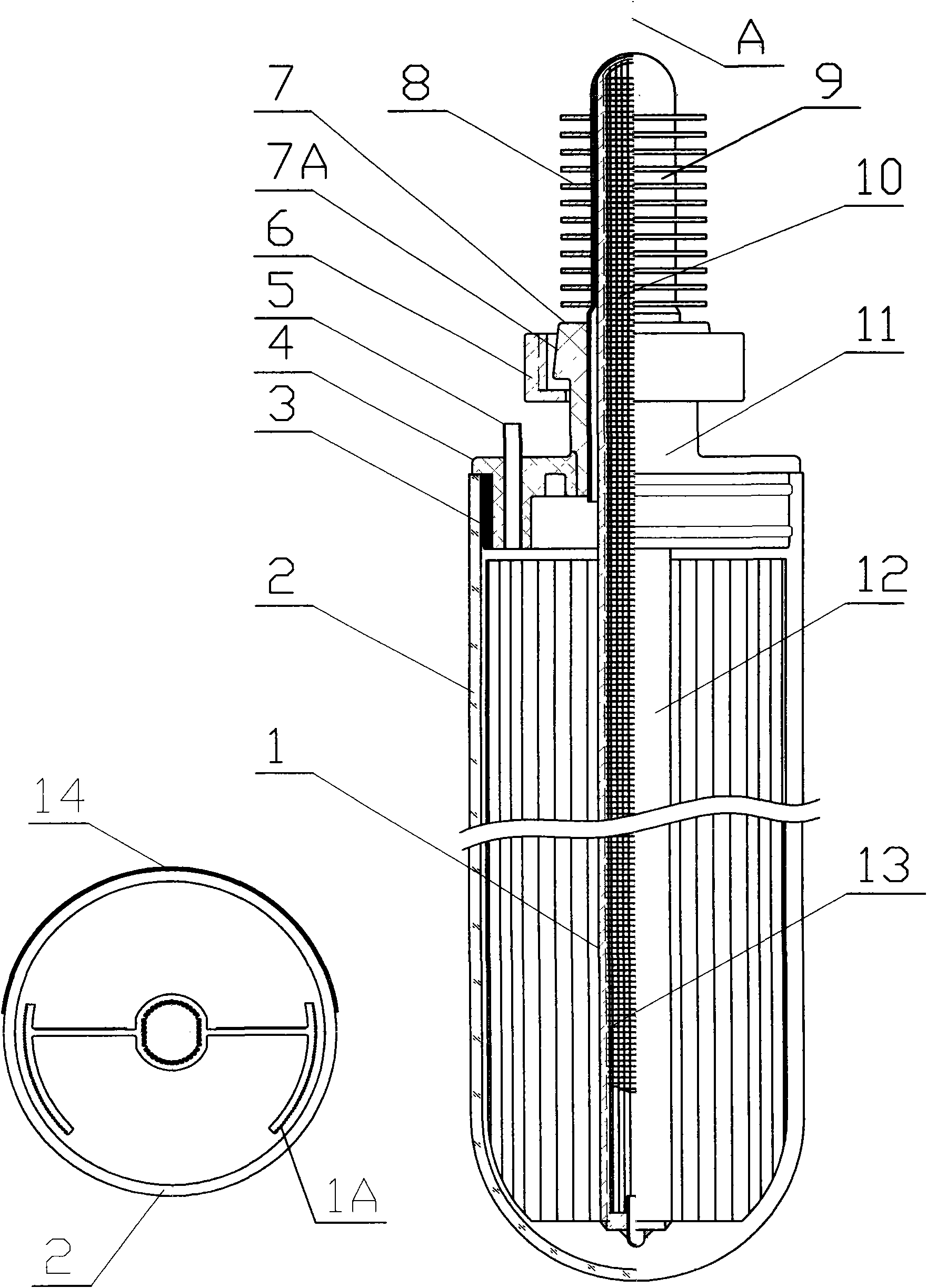

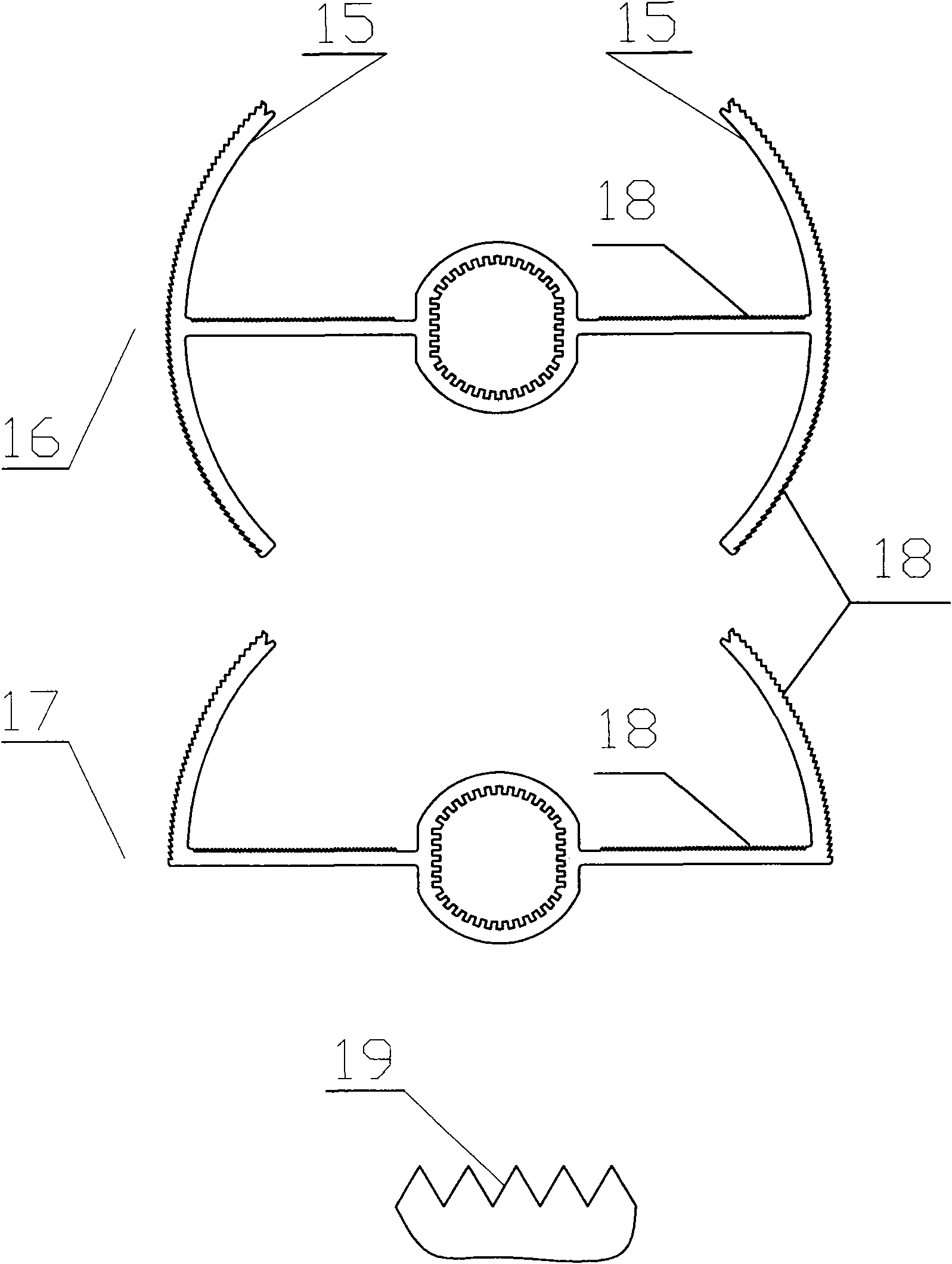

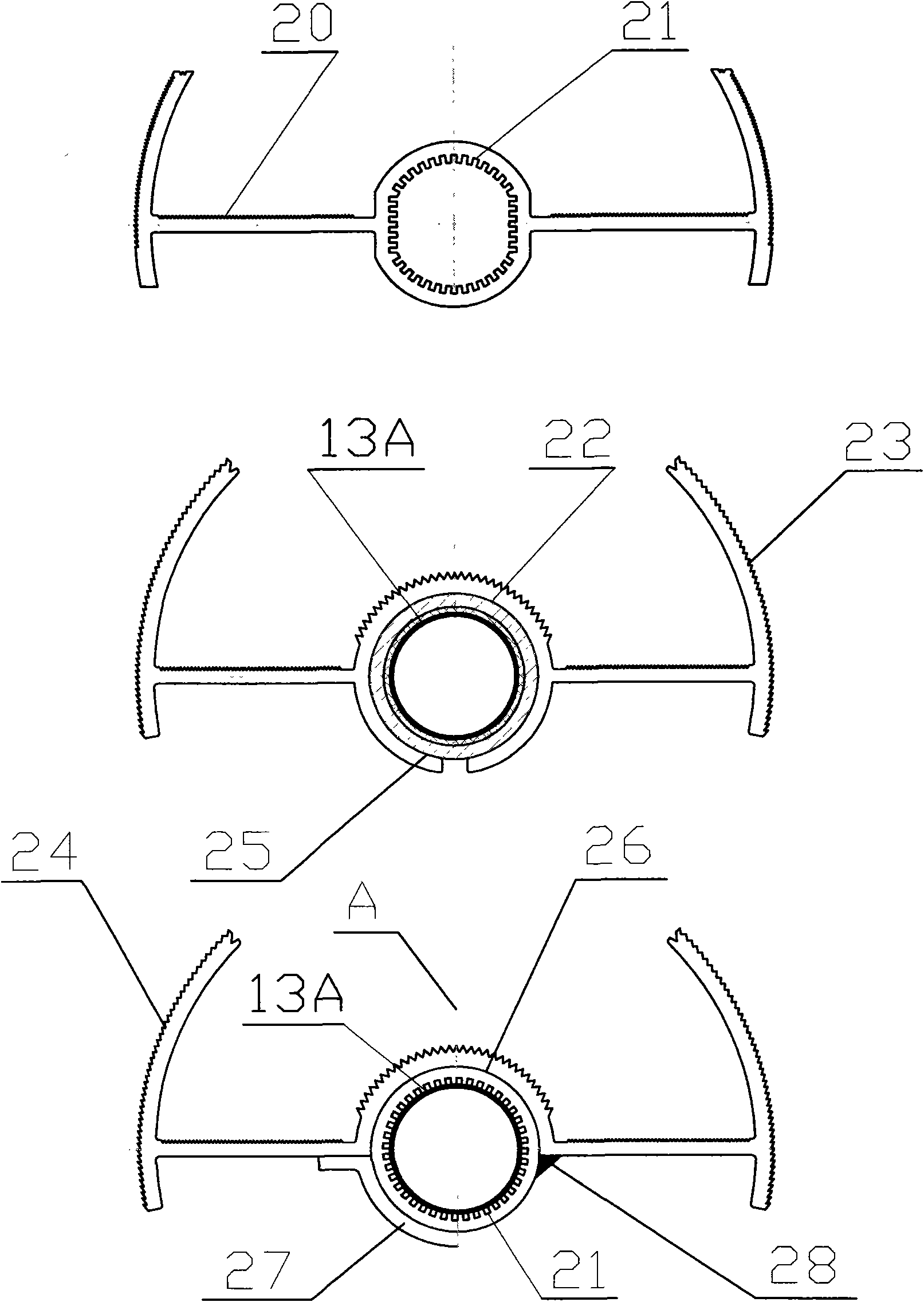

[0033] See attached figure 1 , the solar energy " finned heat pipe " of the present invention, its structure mainly comprises the arc-shaped sail 15 (attached) that is symmetrical with the axial center figure 2 ) composed of sail-shaped finned heat pipe 1, single-layer transparent heat preservation pipe 2, rubber sealing ring 3, exhaust pipe 5, lock nut 6, condensing fin 8, condensing copper pipe 9, double sealing cover 11, reflective film 14, the condensing copper pipe 9 and the exhaust pipe 5 are inlaid on the double sealing cover 11 when the double sealing cover 11 is injected. On the condensing copper tube 9, the condensing copper tube 9 inlaid on the double sealing cover 11 is installed on the condensing section 10 of the sail-shaped finned heat pipe 1, and the rubber sealing ring 3 is installed on the seal on the double sealing cover 11 On the gas cover 4, the gas sealing cover 4 equipped with the rubber sealing ring 3 (select the attached figure 1 or choose to atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com