Measuring tool and measuring method for intersection position of straight holes and taper holes

A technology of tapered holes and tools, which is applied in the field of machinery manufacturing and measurement, can solve the problems of extended production cycle, low processing efficiency, and low processing efficiency, and achieve the effects of very stable size accuracy, reduced labor intensity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

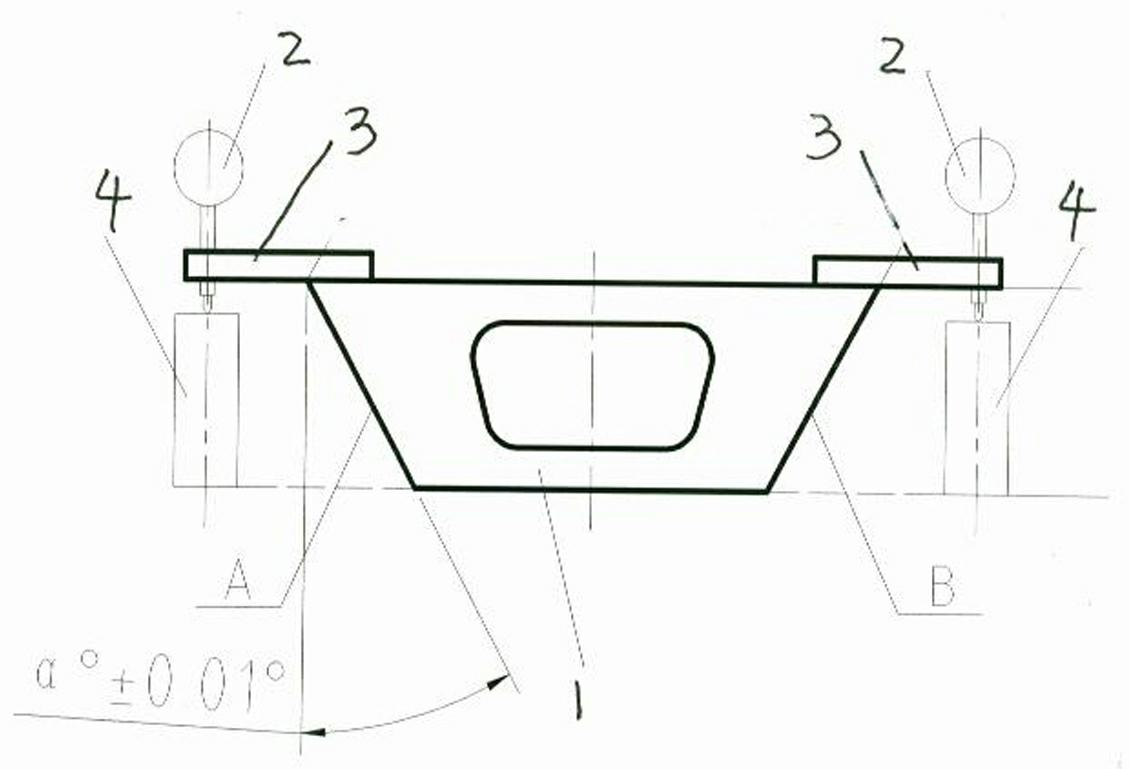

[0019] The present invention will be described in detail below in conjunction with accompanying drawing: figure 2 As shown, the present invention includes a truncated conical gauge main body 1, vertical dial gauges 2 are symmetrically arranged on the edge of its upper end surface, and each of the dial gauges 2 is fixed on the On the main body 1 of the gauge, a height pair gauge block 4 is arranged vertically under the dial indicator 2 .

[0020] The gauge main body 1 has at least the same symmetrical cone surfaces A and B, and the surface roughness Ra of the cone surfaces A and B is 0.1, and the straightness is 0.004.

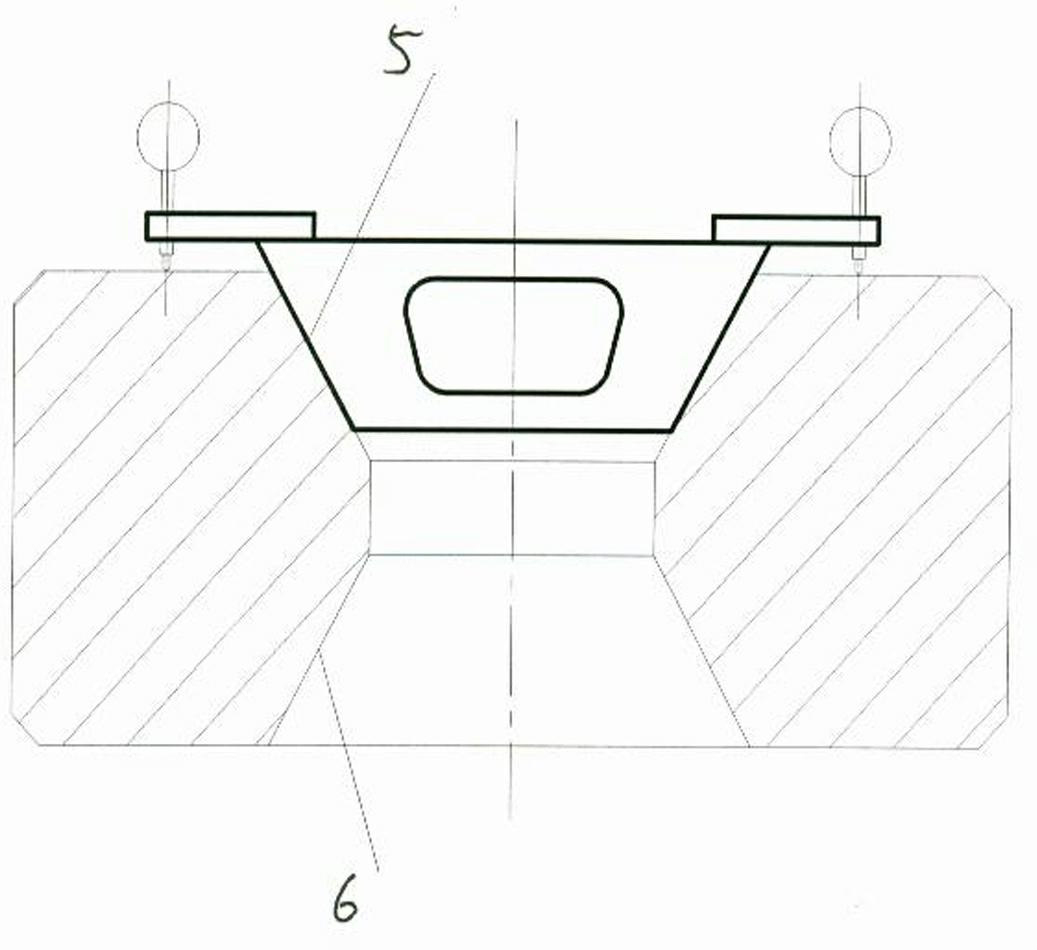

[0021] A kind of measuring method that utilizes the measuring tool of the intersection line position of straight hole and taper hole as mentioned above, see image 3 As shown, the method is: when measuring, first place the gauge on the flat plate, and the dial indicators 2 on both sides use the height to zero the gauge block 4 at the same time, and measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com