Novel calcination-free desulfurized gypsum brick

A desulfurized gypsum, calcination-free technology, applied in the field of building bricks, can solve the problems of polluting the environment, land occupation by coal-fired power plants, etc., and achieve the effects of high product quality, low cost, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

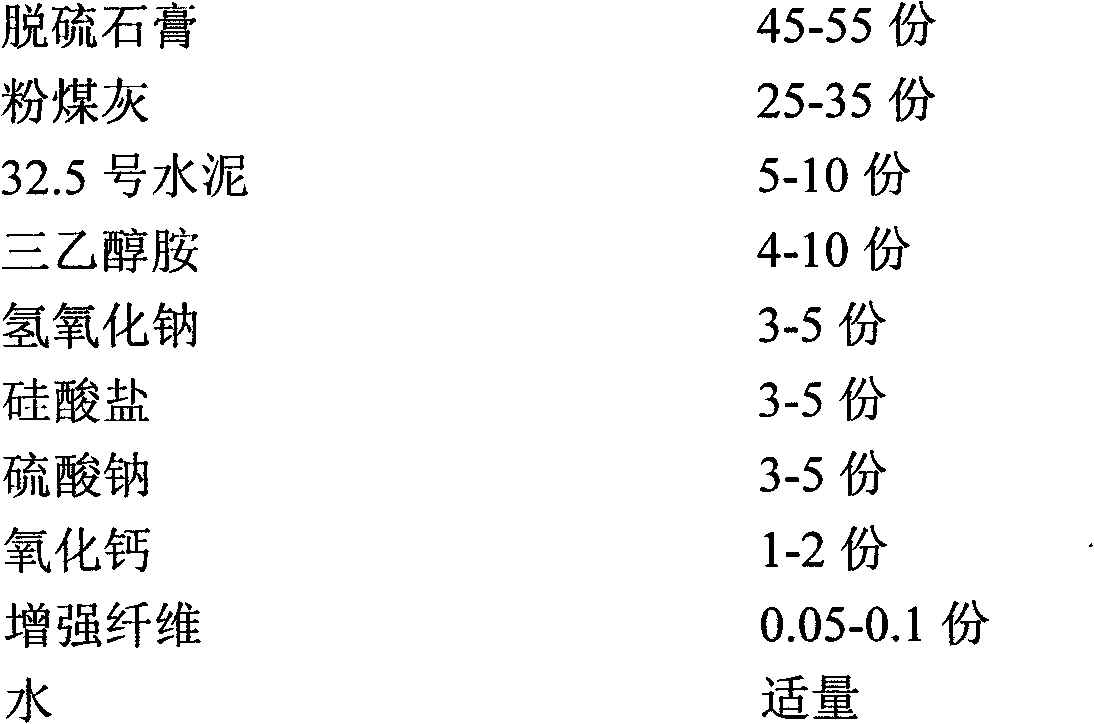

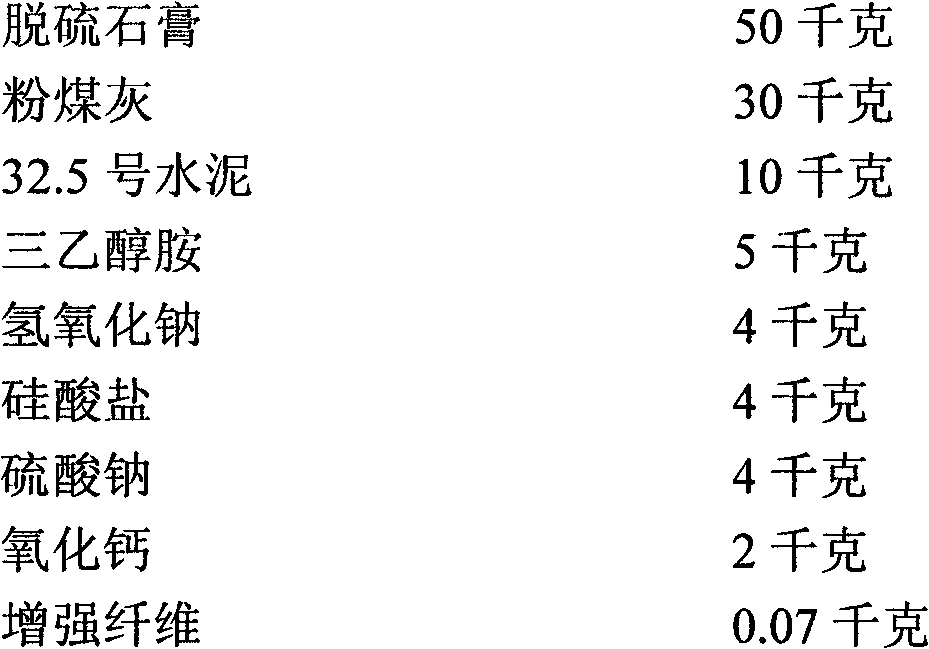

[0016] Produce new type non-calcined desulfurization gypsum bricks according to the following quality:

[0017] formula

[0018]

[0019] Mix and stir desulfurized gypsum, fly ash, cement, sodium hydroxide, sodium silicate, sulfate, and calcium oxide according to the above ratio, and then add triethanolamine and reinforced fiber aqueous solution according to the ratio and mix evenly. The ratio of water to material is 0.48;

[0020] The mixture is vibrated and pressed into the mold, and the pressure is 100-300 Newton during the compression. After the test piece is formed, let it stand at room temperature for 3 days before demoulding. After demoulding, it will be naturally cured for 25 days to obtain the finished desulfurized gypsum brick.

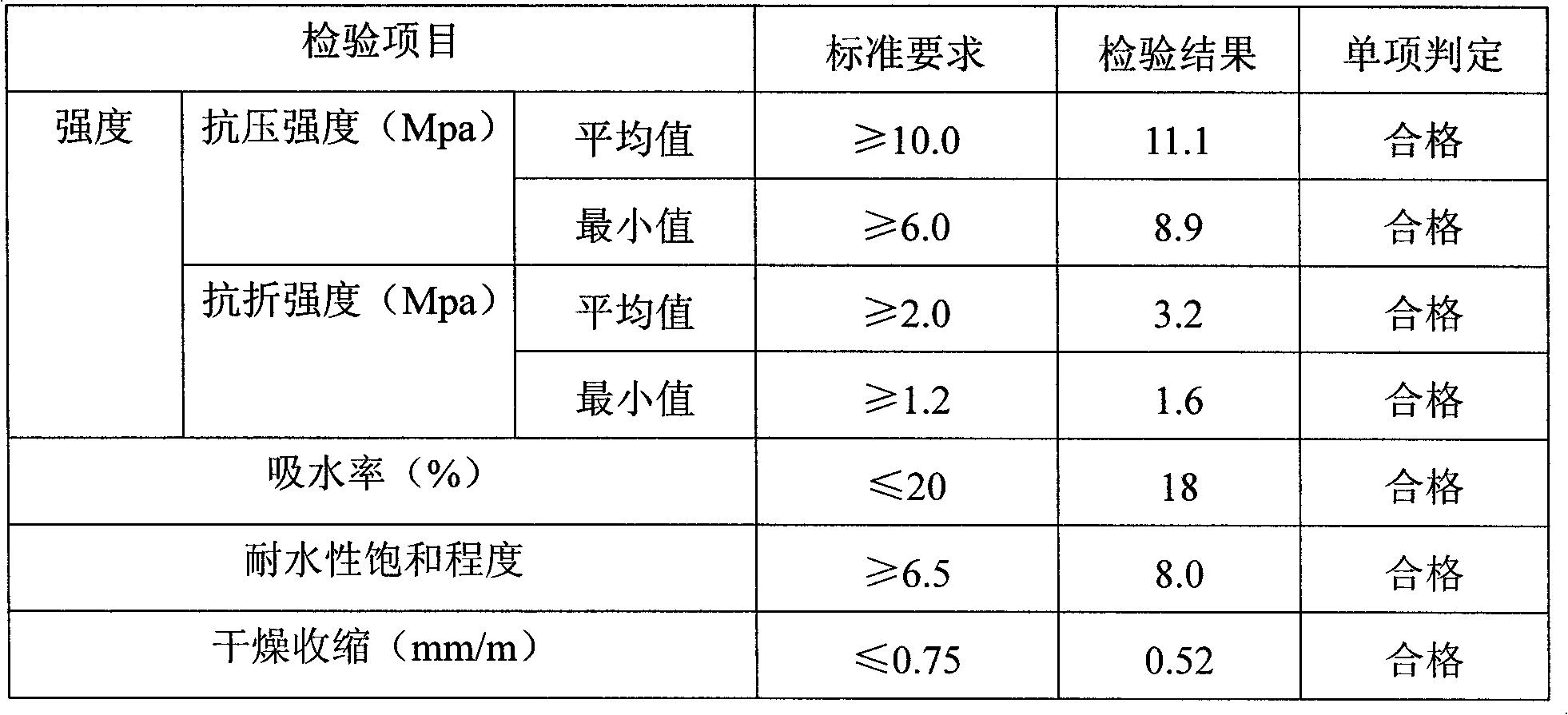

[0021] The technical indicators of the obtained new-type calcined-free desulfurization gypsum bricks are shown in Table 1:

[0022] Table I:

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com