Method for preparing acarbose through microbial fermentation

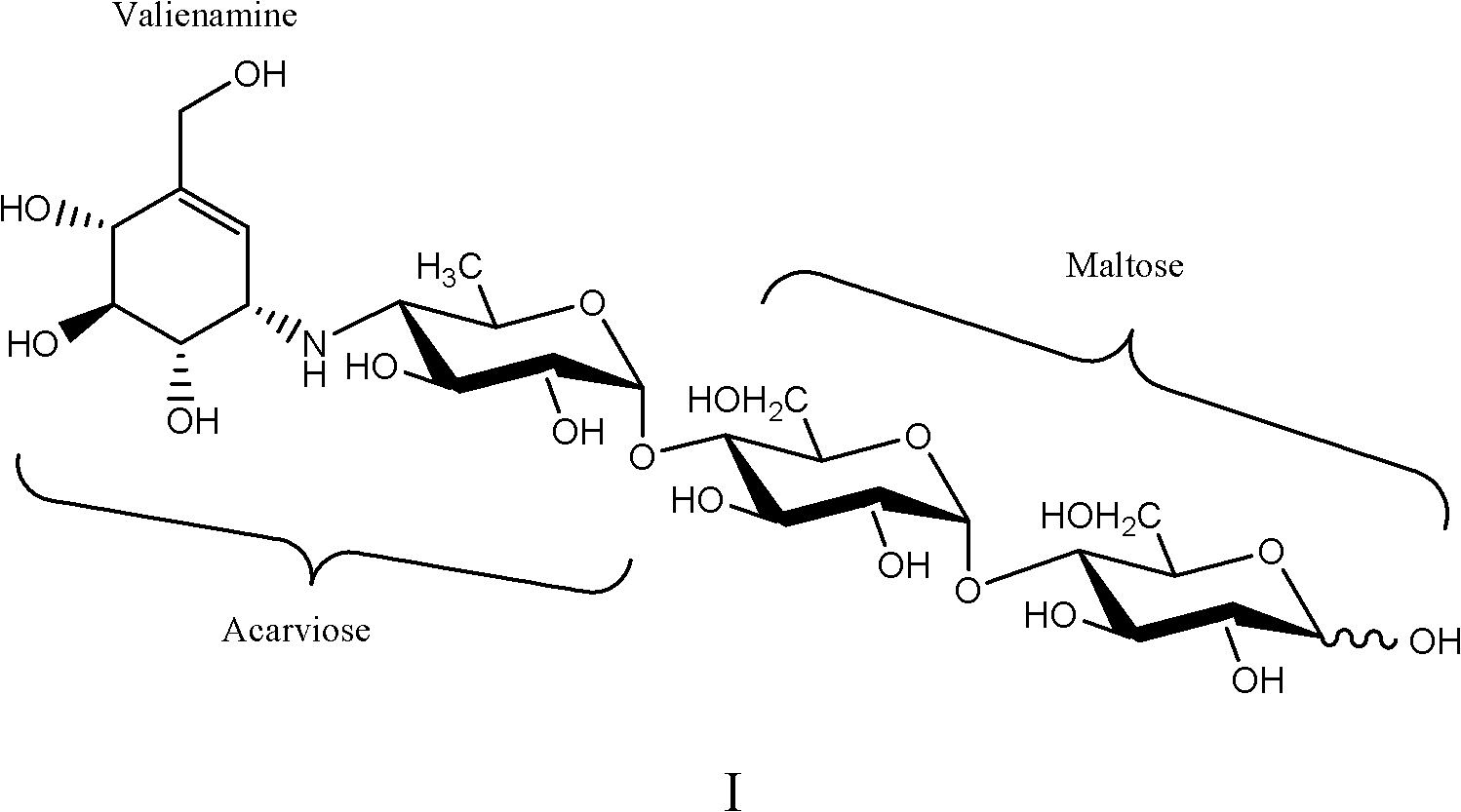

A technology for microbial fermentation and acarbose, applied in the field of fermentation, can solve the problems of reducing maltose content and affecting the yield of acarbose, and achieves the effects of improving the fermentation level and the fermentation titer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

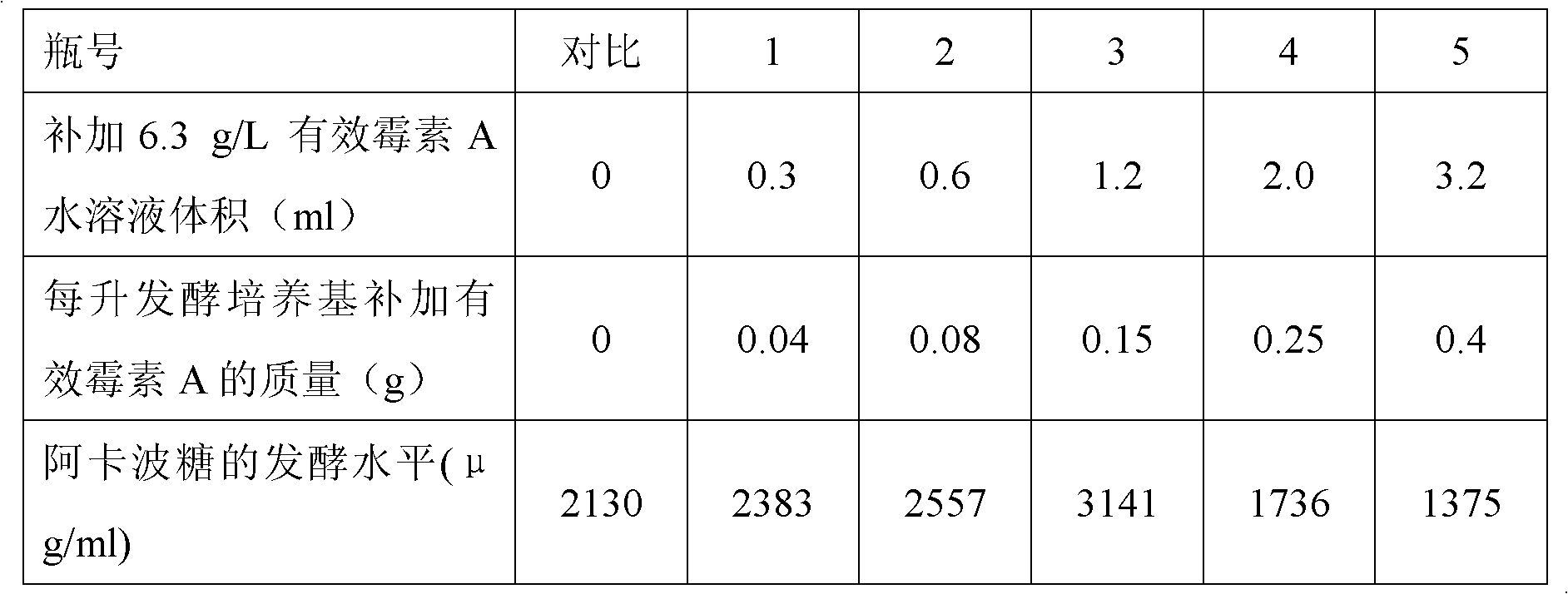

[0042] Embodiment 1: the production of acarbose (erlenmeyer flask shaking fermentation)

[0043] Prepare seed culture medium, its culture medium composition is as follows: cornstarch 15.0g / L, soybean cake powder 40.0g / L, glycerol 20.0g / L, K 2 HPO 4 0.1g / L, CaCO 3 2.0g / L, prepared with tap water, initial pH 7.0. Sterilized at 121°C for 30 minutes.

[0044] Preparation of fermentation medium, the composition of the medium is as follows: maltose syrup 80.0g / L, glucose 20.0g / L, soybean cake powder 10.0g / L, corn steep liquor 5.0g / L, FeCl 3 0.1g / L, CaCl 2 2.0g / L, CaCO 3 6.0g / L, prepared with tap water, pH 7.0. Sterilized at 121°C for 30min.

[0045] Prepare validamycin A aqueous solution: use tap water to prepare validamycin A solution with validamycin A concentration of 6.3 g / L, and sterilize at 121° C. for 30 minutes.

[0046] Seed preparation: Aseptically transfer the CCTCC NO: M 209022 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate...

Embodiment 2

[0052] Embodiment 2: the production of acarbose (stirred reactor fermentation)

[0053] The preparation of seed culture medium and fermentation medium is the same as in Example 1.

[0054] Preparation of validamycin A aqueous solution: use tap water to prepare validamycin A solution with validamycin A concentration of 12 g / L, and sterilize at 121° C. for 30 minutes.

[0055] Seed preparation: Aseptically transfer the CCTCC NO: M 209022 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate it at 28°C for 2 days, pick the colony and inoculate it in a 500ml triangular flask for seed cultivation, the volume of the seed medium in the bottle 50ml, shaker rotation speed 200rpm, cultivated at 28°C for 72h to obtain seed solution.

[0056] Fermentation of Acarbose:

[0057] Take 24L of the above-prepared fermentation medium and put them into three 15L stirring fermenters respectively, each fermenter is filled with 8L fermentation medium, sterilized at 12...

Embodiment 3

[0061] Embodiment 3: the extraction of acarbose

[0062]Get 100 milliliters of fermented liquid in bottle No. 12 of Example 12, adjust the pH value to 3, centrifuge at 3000 × g for 10 minutes, discard the precipitate, and collect the supernatant; the clarified supernatant is initially separated by macroporous cation exchange. The chromatographic column is a 2.5×30 cm glass column (BIO-Rad, USA). For primary separation chromatography, UNOsphere S filler with a particle size of 80 microns was selected, and the column was packed by wet method. The bed height was about 22.3 cm, and the medium used was 5.0×10 -2 M hydrochloric acid dilute acid transformation into H + type. The flow rate of the mobile phase was set to 440 ml / hour (linear velocity 1.5 cm / min). After fully equilibrating, take 2.0 ml of concentrated solution with a concentration of 5 g acarbose / liter concentrated solution for loading, and wash 7 samples with ultrapure water. Column volume, eluted with 5.0×10 -3 M h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com