Environmentally-friendly water-soluble quenching medium

A quenching medium, water-soluble technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of application limitations, inability to use directly, restrictions, etc., achieve good sterilization and surface activity, prevent bacterial growth, and good anti-embroidery and defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Configure a water-soluble quenching medium suitable for low quenching temperature with a concentration of 15%. In terms of mass percentage, the amount of polyether with a molecular weight of 20000-30000 is 14.5%, and the amount of polyether with a molecular weight of 5000-15000 is 0.5%. The consumption of base-3(2H)-isothiazolinone is 1.0%, the consumption of ethyl silicone oil is 0.1%, and the consumption of the quaternary ammonium salt and the quaternary phosphonium salt bactericide that the ratio is 15:1 is 500ppm, by Japanese Central Chemical Co., Ltd. The amount of AO-10 type surfactant produced by the company is 500ppm, the amount of pH regulator is 0.3%, and the amount of tap water is 83.5%.

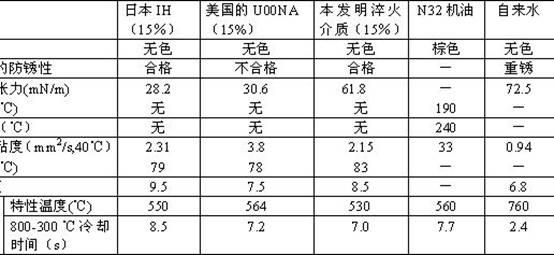

[0027] The performance and cooling characteristics of the water-soluble quenching medium with a concentration of 15% are shown in Table 1

[0028] Table 1 Performance and cooling characteristics of several quenching media

[0029]

Embodiment 2

[0031] Configure a water-soluble quenching medium with a concentration of 15% suitable for high quenching temperatures. The amount of polyether with a molecular weight of 20,000-30,000 is 0.5%, and the amount of polyether with a molecular weight of 5,000-15,000 is 14.5%. 2-Methyl-3 (2H) - The amount of isothiazolinone is 0.5%, the amount of ethyl silicone oil is 0.2%, the amount of quaternary ammonium salt and quaternary phosphonium salt fungicide with a ratio of 10:1 is 800ppm, AO-10 produced by Japan Chuo Chemical Co., Ltd. Type surfactant consumption is 200ppm, and the consumption of pH value adjusting agent is 0.2%, and the consumption of tap water is 84%.

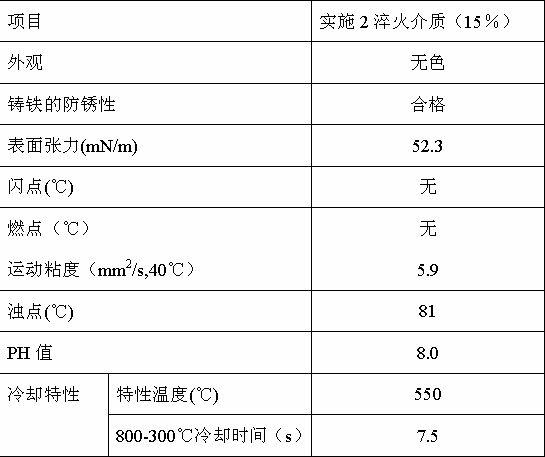

[0032] The performance and the cooling characteristic of the water-soluble quenching medium of the embodiment 2 of configuration are as table 2

[0033] Table 2 Performance and cooling characteristics of the quenching medium in Example 2

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com