Method for preparing manganese sulfate from leaching slag of electrolytic manganese metal

A technology for electrolysis of metal manganese and leaching of slag, applied in the direction of improving process efficiency, etc., can solve the problems that manganese sulfate is difficult to meet the quality standard of nickel-cobalt-manganese secondary positive electrode material, large equipment investment, and high operation requirements, and achieves significant ecological benefits and Environmental benefits, less equipment investment, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

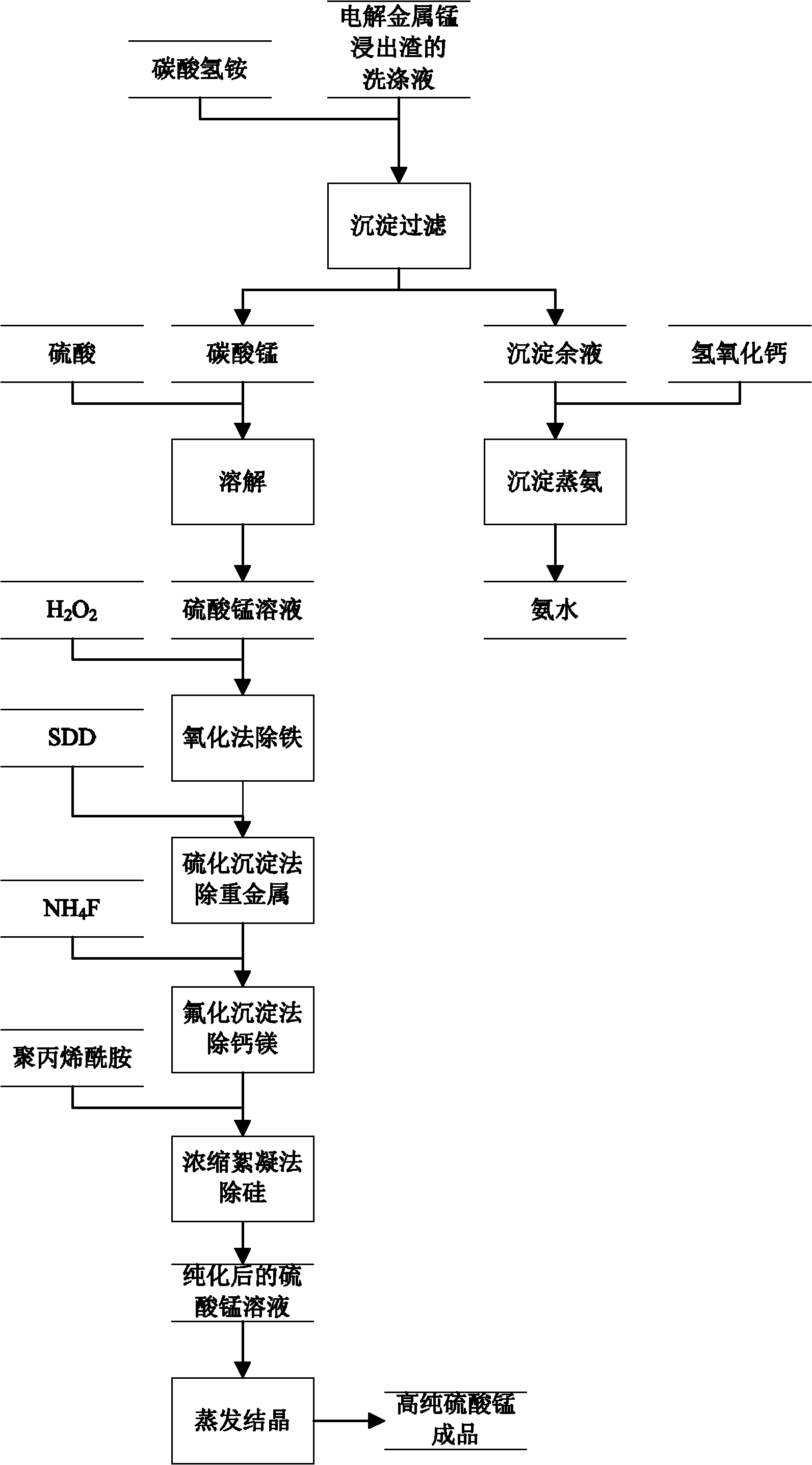

[0021] a kind of like figure 1 Shown the present invention prepares the method for manganese sulfate with electrolytic metal manganese leaching slag, comprises the following steps:

[0022] 1. Preparation of manganese carbonate: using the washing solution of electrolytic manganese metal leaching slag in a certain electrolytic manganese process as raw material, after testing, the washing solution contained Mn 37.82g / L, containing (NH 4 ) 2 SO 4 91.82g / L, and then use ammonium bicarbonate to precipitate the washing solution. The amount of ammonium bicarbonate is 1.1 times the theoretical amount. The temperature during precipitation is 40°C, and the stirring time is 30min. After filtration and separation, manganese carbonate precipitation and precipitation residue are obtained. (The precipitation residue mainly contains ammonium sulfate). The reaction principle of this step is:

[0023] MnSO 4 +2NH 4 HCO 3 =MnCO 3 +(NH 4 ) 2 SO 4 +H 2 O+CO 2 ↑.

[0024] 2. Sulfuric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com