Energy storage sodium-sulfur battery module with high safe protection design

A sodium-sulfur battery, safety protection technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of battery failure, poor thermal conductivity, battery electrochemical chain damage, etc., and achieve the effect of preventing secondary disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

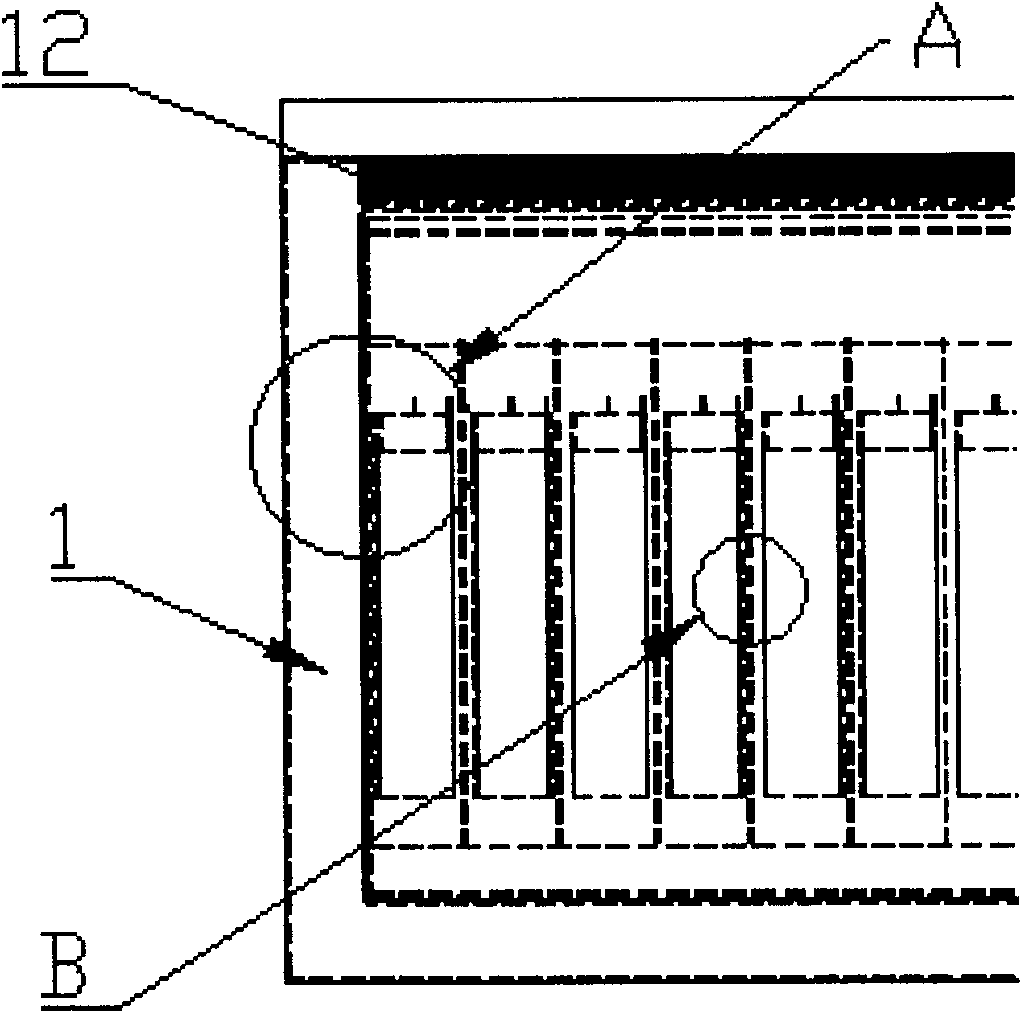

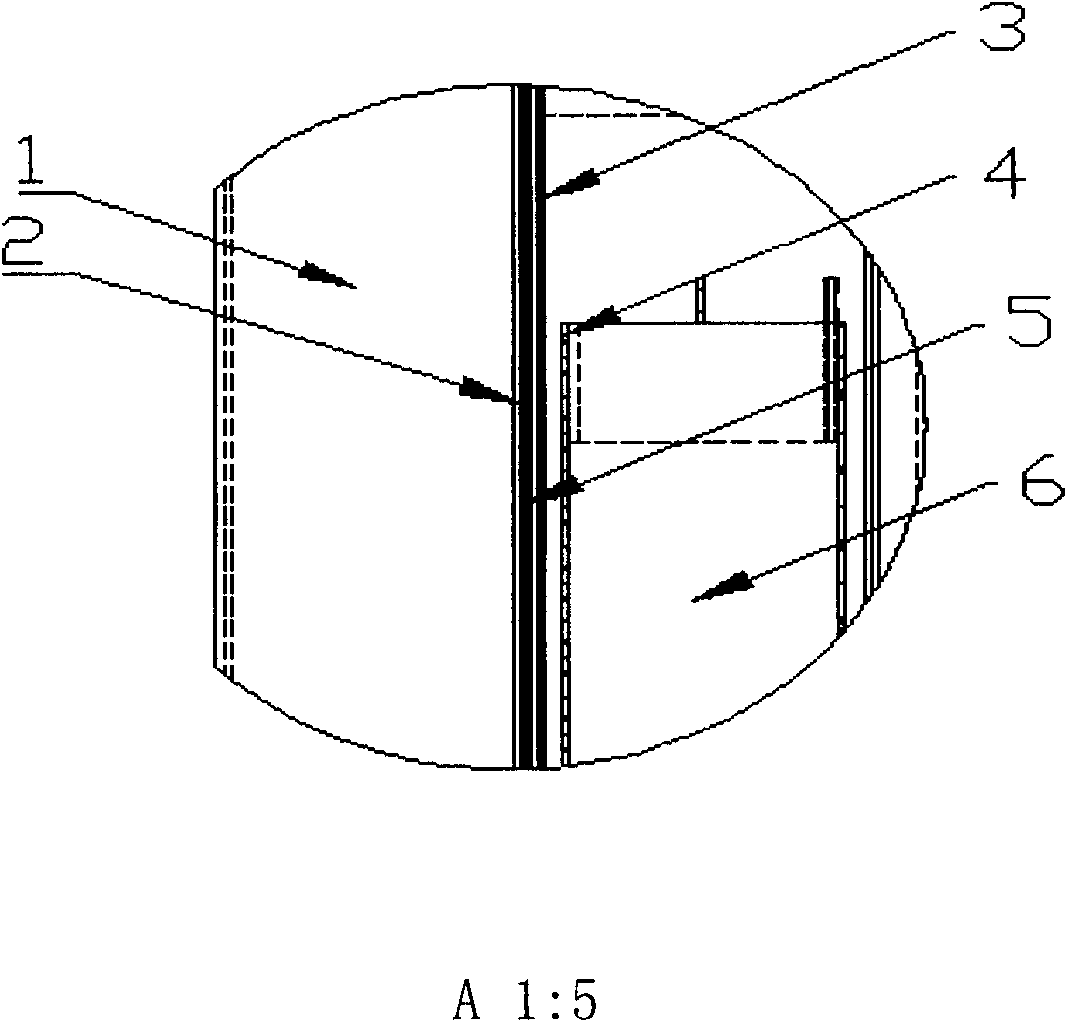

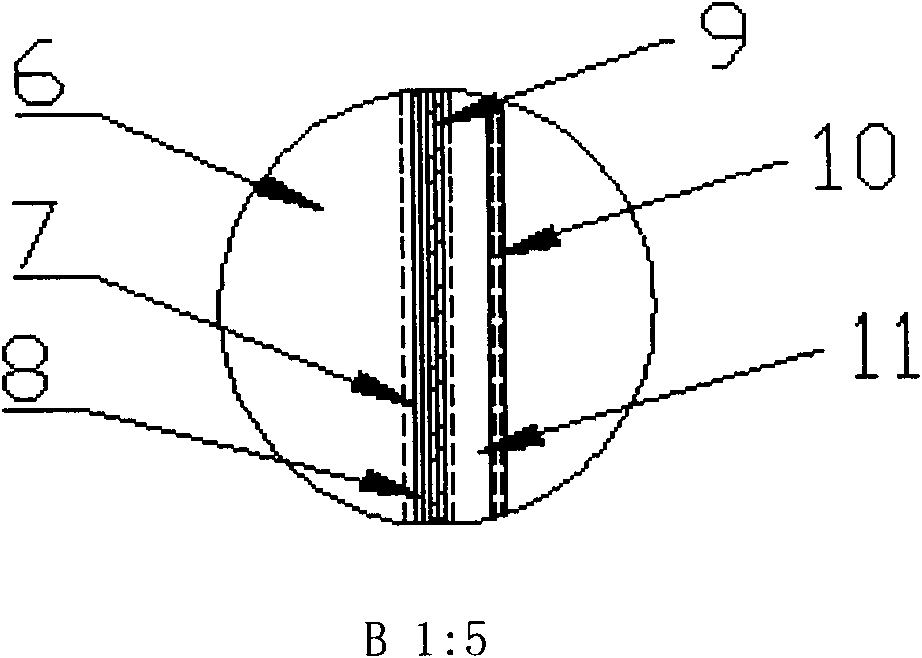

[0058] figure 1 A partial side view of an energy storage sodium-sulfur battery module with a high safety protection design with an outer size of 1070×1010×980mm made according to the present invention is given, figure 2 , image 3 It further provides the isolation side structure between the module insulation layer and the battery, and between the battery and the battery. The outside of the module adopts stainless steel structure, the total thickness of the insulation layer of the module incubator is 7cm, and the constant temperature power is Figure 4 The electrical schematic diagram of the energy storage sodium-sulfur battery module with high safety protection design is given. The battery management system can perform functions including signal acquisition, monitoring and automatic switching. After the module reaches the working temperature, it will be charged and discharged, and some batteries will be forced to charge and fail. After the three batteries have a short circ...

Embodiment 2

[0060] The energy storage sodium-sulfur battery module with a high safety protection design and an outer dimension of 1570×1010×1180 mm manufactured according to the invention. The exterior of the module adopts a carbon steel structure, the total thickness of the insulation layer of the module insulation box is 7cm, and the constant temperature power is less than 300W. There are a designed number of large-capacity sodium-sulfur single batteries inside the module. The single batteries are connected in series in groups of 9, and each group of batteries is connected in parallel. The voltage of each series-connected battery group is passed through the battery management system designed near the module. to monitor. In the middle of the module and near the heating layer of the incubator in the module, batteries with ruptured electrolyte or unqualified sealing are deliberately placed. After the module reaches the working temperature, it will be charged and discharged. The battery wit...

Embodiment 3

[0062] An energy storage sodium-sulfur battery module with a high safety protection design and an outer dimension of 1900×1200×1000 mm manufactured according to the invention. The exterior of the module adopts carbon steel structure, the total thickness of the insulation layer of the module insulation box is 7cm, and the constant temperature power is less than 400W. There are a designed number of large-capacity sodium-sulfur single batteries inside the module. All the single batteries are connected in series, and the voltage is monitored in groups of three. Working status monitoring such as temperature and current is carried out by designing a battery management system near the module. In the four corners of the module, as well as in the middle and near the heating layer of the incubator in the module, a total of 1 / 4 (accounting for the total number of batteries in the module) are deliberately put in 1 / 4 (accounting for the total number of batteries in the module) batteries wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com