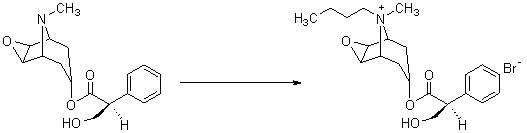

Preparation method of scopolamine butylbromide

A technology of scopolamine and scopolamine, which is applied in the field of preparation of scopolamine butylbromide, can solve the problems of no application value, low method yield and high price, and achieves the effects of easy recovery and processing, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific implementation examples.

[0025] (1) Preparation of crude scopolamine butylbromide

[0026] Add 10 grams (0.033 moles) of scopolamine to a 100ml round bottom flask equipped with a glass condenser,

[0027] 30ml (0.278 moles) of n-butane bromide was stirred, heated in a water bath, and refluxed at 90°C for 30 hours. After the reaction is complete, cool the reactant to room temperature, remove the oily liquid, concentrate the residue to dryness under reduced pressure at 75°C, add 30ml of absolute ethanol, heat to dissolve, place at room temperature, precipitate crystals and place in the refrigerator (8~10°C) overnight. After filtering, the crystals were washed with absolute ethanol, sucked dry, and dried under vacuum at 70°C for 4 hours to obtain 9.6 g of crude scopolamine butylbromide.

[0028] (2) refined

[0029] Add 9.6g of crude scopolamine butylbromide and 45ml of absolute ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com