Non-polar surface GaN epitaxial wafer and preparation method of non-polar surface GaN epitaxial wafer

A non-polar surface, epitaxial wafer technology, applied in chemical instruments and methods, from chemical reactive gases, single crystal growth, etc., can solve the problems of reducing the luminous efficiency of GaN thin films, blue shift of diode luminescence peaks, and many defects. , to achieve the effect of improving quantum efficiency and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

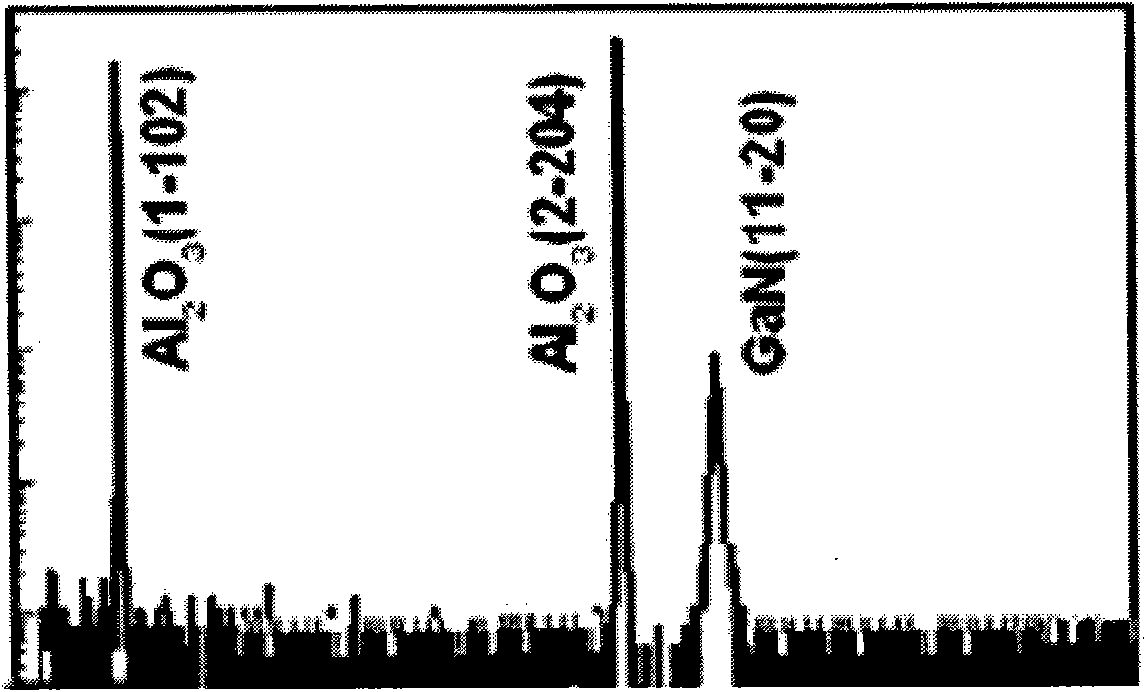

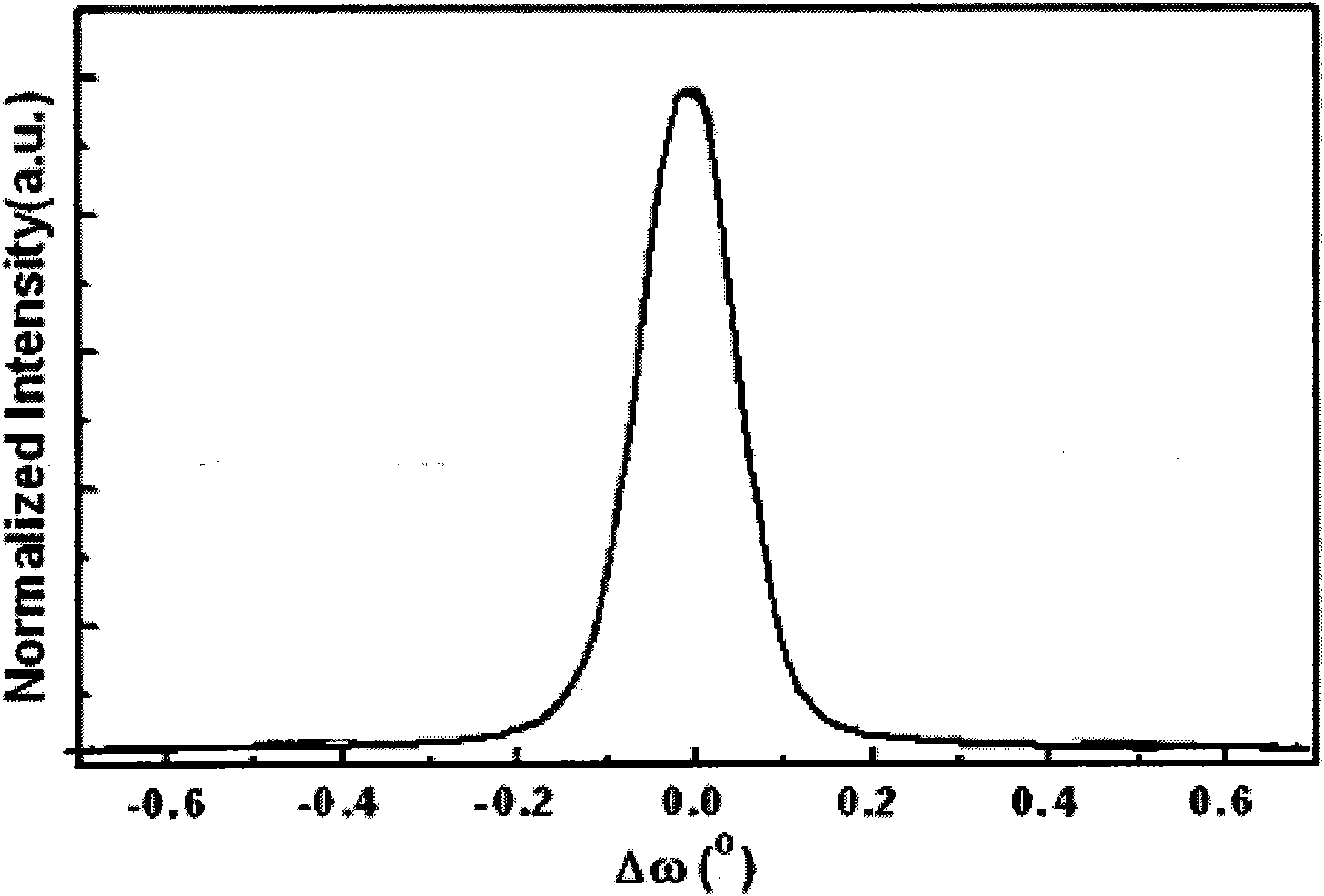

[0011] A method for preparing a non-polar GaN epitaxial wafer comprises the steps of: growing a buffer layer on a substrate; growing an a-plane GaN thin film on the buffer layer; further, the substrate is an r-plane sapphire substrate; further , the buffer layer is Al grown by metal-organic source vapor phase epitaxy 0.15 Ga 0.85 N, wherein the source of Al is trimethylaluminum, the source of gallium is trimethylgallium, and hydrogen is used as a carrier gas; further, when depositing the buffer layer, the growth temperature is 700°C, the V / III ratio is 6000, and the thickness is 20nm .

[0012] Please refer to figure 1 , Put the no-clean r-plane single-polished sapphire substrate into the growth chamber of the metal-organic source vapor phase epitaxy (MOCVD) material growth system, slowly raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com