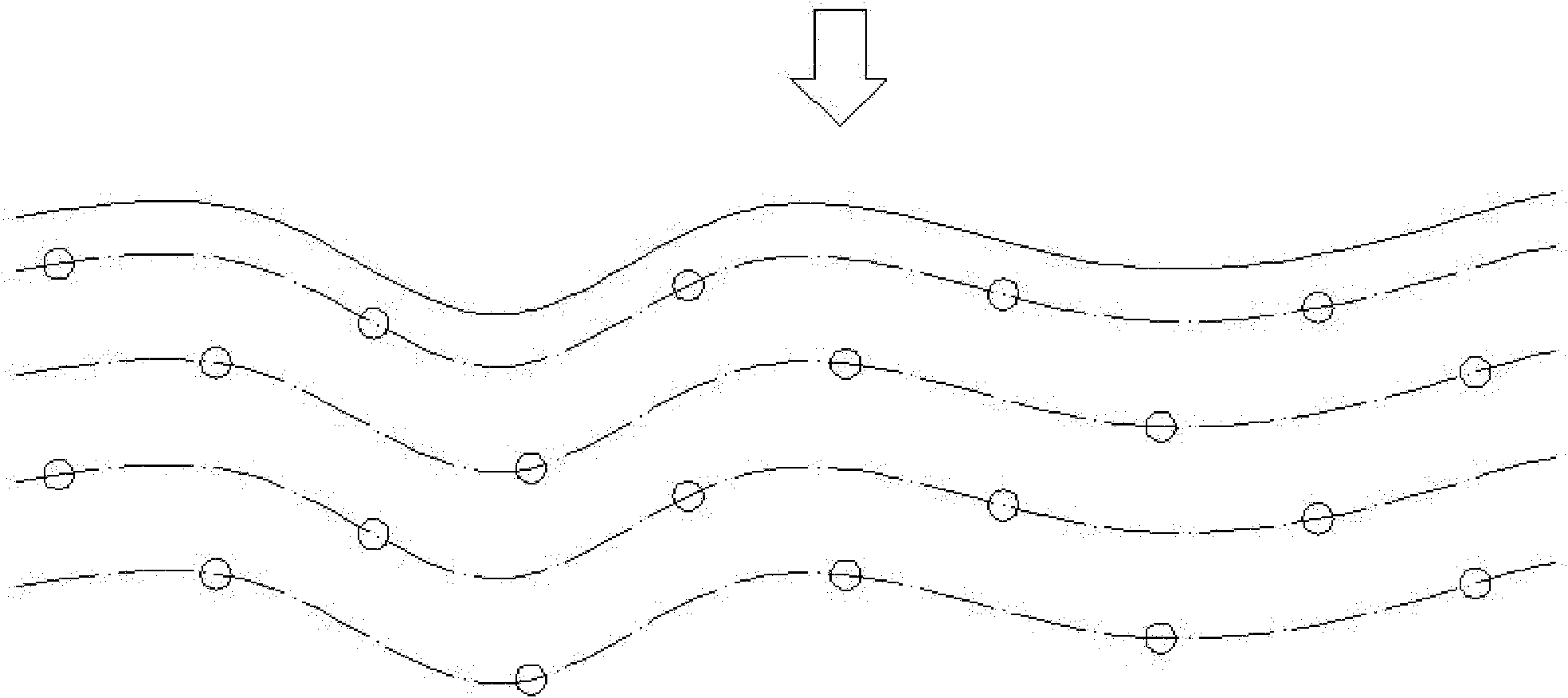

Reverse hole distributing method used in longhole bench blasting

A technology for step blasting and hole layout, applied in blasting and other directions, can solve the problems of unevenness, unfavorable blasting standardization, and unfavorable drilling rig efficient operation, etc., and achieves the effect of neat slope top line, convenient standardized operation, and standardized operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A quarry has an average monthly blasting volume of 600,000 m 3 (solid cube), a large-scale stone blasting project with a daily output of 40,000 cubic meters (solid cube). The rock formation in the mining area is biotite monzonite granite, the f value is 11-14, and the saturated compressive strength is 70-150MPa. The geological conditions in the mining area are complex, with well-developed joints, fissures, weathered trenches, and broken zones, and rich fissure water.

[0055] This project has the characteristics of large-scale blasting operations, frequent blasting times, many specifications of stone materials that require one-time blasting, strict blasting quality requirements, and narrow blasting operations.

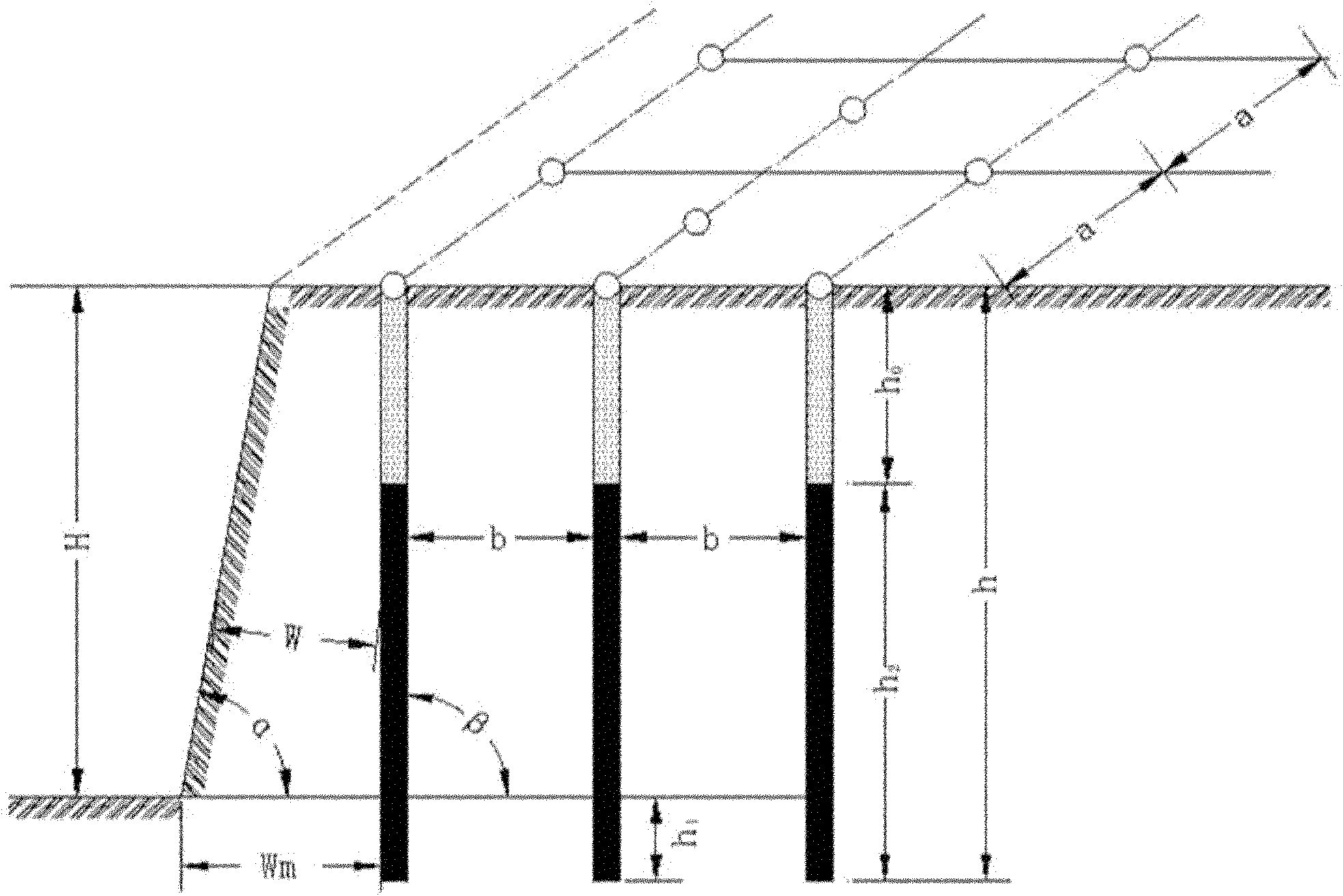

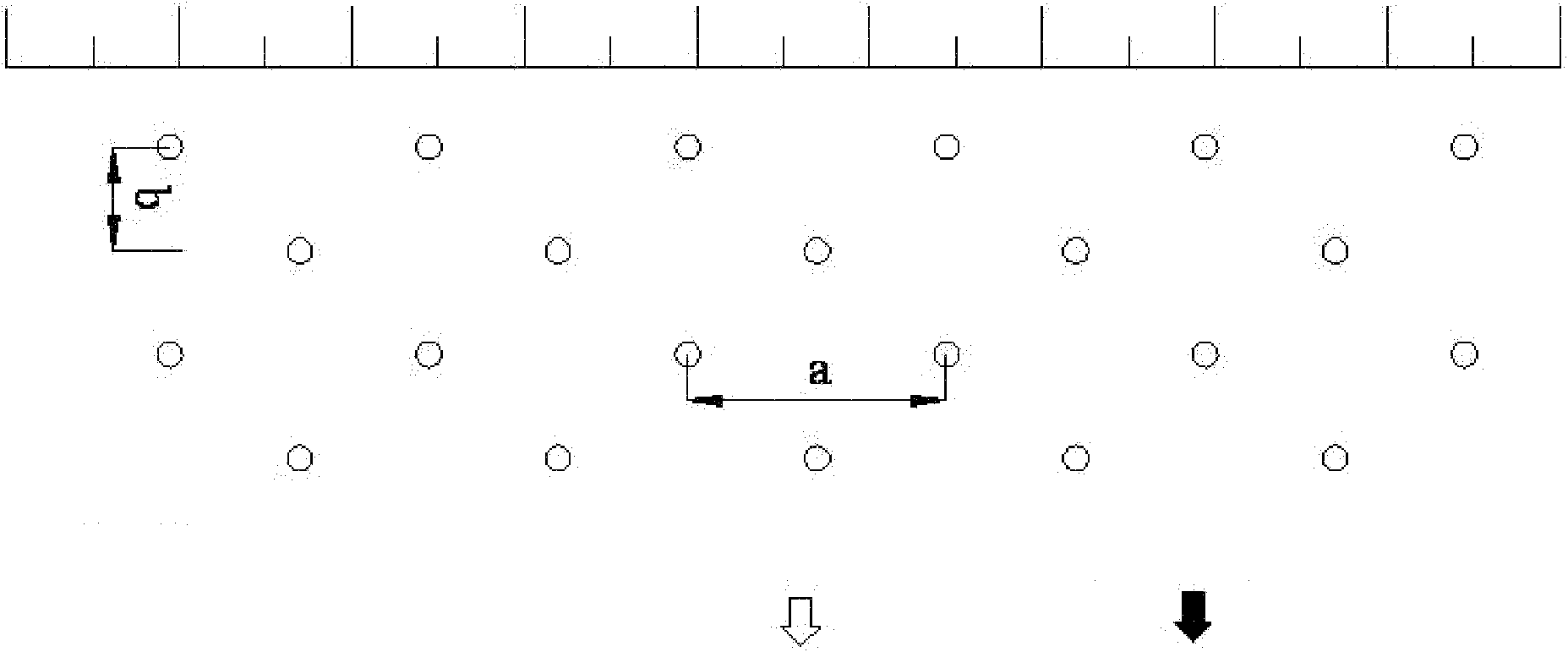

[0056] Drilling equipment is Ingersoll Rand VHP750 down-the-hole drilling rig; step height H=15.0m, vertical hole, hole diameter Φ=140mm; for granite with f=11~14 ultra-deep 0.3~1.5m, hole spacing is mostly 5m, row The distance is mostly 4m.

[0057] In actua...

Embodiment 2

[0059] In 2009, an important blasting earthwork project in Northeast China contracted by our company was divided into two tenders. The total engineering volume of rock blasting in one of the bidding sections is about 10.38 million m 3 (Natural side), earthwork stripping 590,000 m 3 (natural side). The contract requires a construction period of 250 calendar days, and an average of 41,400 m of stones need to be shipped every day 3 , reaching 80,000 m per day during the peak period 3 . The total amount of earth and stone in the second tender section is 9,959,352 cubic meters, of which 497,968 cubic meters of topsoil is cleared and 9,461,384 cubic meters of stone is blasted. The construction period is 213 days. The construction period is tight and the task is heavy.

[0060] Aperture diameter 140mm; hole spacing 5-5.5m; row spacing 4-4.2m; hole depth 15m, super-deep 0.5-1.5m; average unit consumption 0.4kg / m 3 .

[0061] In actual work, due to the relatively heavy engineerin...

Embodiment 3

[0063] The Shenhua Zhungeer open-air stripping project undertaken by our company is located in the northeast of the Ordos Plateau, adjacent to the Yellow River in the east, and the terrain is high in the northwest and low in the southeast. Loess and red soil are widely distributed on the bedrock, the ground vegetation is sparse, the terrain is cut and broken, the gullies are deep, and the slope is large, which is easy for water drainage.

[0064] The total amount of stripping in the second phase is 12.1675 million m 3 , and the construction period is 245 days. The rock in the stripping area is semi-hard-hard rock, with a compressive strength of 8.14MPa-50.80MPa, generally greater than 9.81Mpa, most of which are greater than 19.61Mpa. The Platinum hardness coefficient is 1.93-5.90, and the bulk density of the rock is 2.4t / m 3 .

[0065] A roller cone drill with a diameter of 250mm is used to drill holes, the hole network parameters are 8×10m, the height of the main blasting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com