Oxide resistor storage device and preparation method thereof

A resistance storage and oxide technology, applied in the direction of electrical components, etc., can solve the problems of resistance change stability, cycle durability resistance state retention characteristics and other unsatisfactory performance, to enhance data retention characteristics, improve reliability characteristics, preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

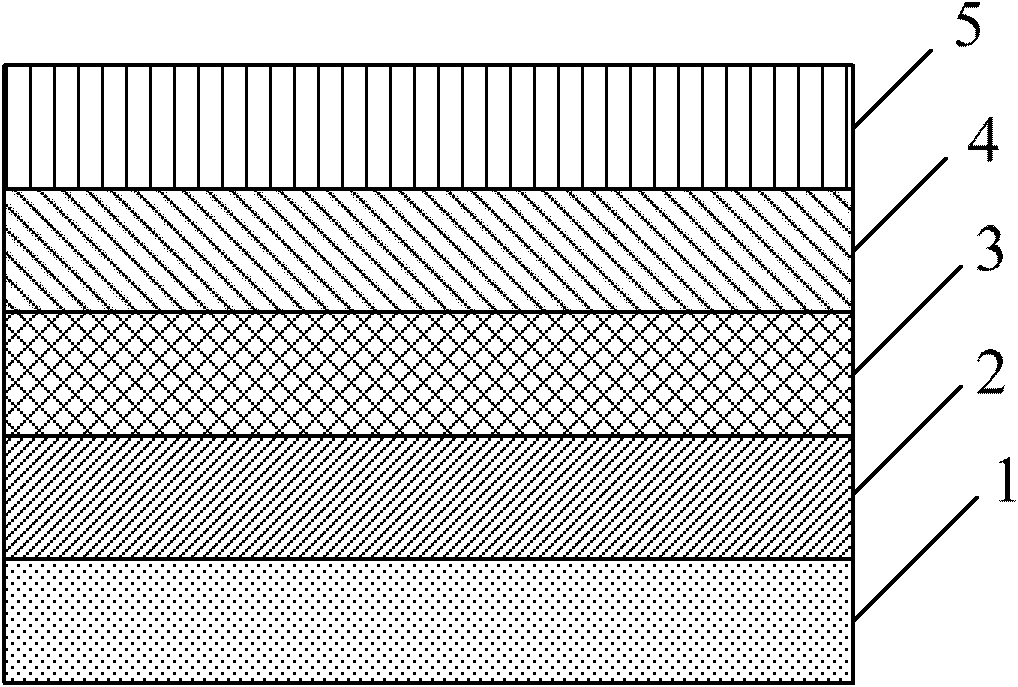

[0029] Such as figure 1 As shown, the present invention provides an oxide resistance memory device, comprising a substrate 1, a bottom electrode 2 on the substrate 1, an oxide control layer 3 on the bottom electrode 2, and an oxide control layer 3 on the oxide control layer 3. The oxide resistive layer 4, and the top electrode 5 located on the oxide resistive layer. Substrate 1 selection material SiO 2 / Si,Al 2 o 3 , borosilicate glass or quartz glass. The top electrode 5 is made of thin film material platinum / titanium (Pt / Ti), gold / titanium (Au / Ti), titanium (Ti), tungsten (W), tantalum (Ta), TiN, TaN, strontium niobate-doped titanate Either made. The bottom electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com