Redox flow battery system

A liquid flow battery and liquid flow technology, which is applied in the direction of fuel cells, secondary batteries, fuel cell additives, etc., can solve problems such as difficult power output, improve utilization rate, improve charge and discharge performance, and reduce leakage current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

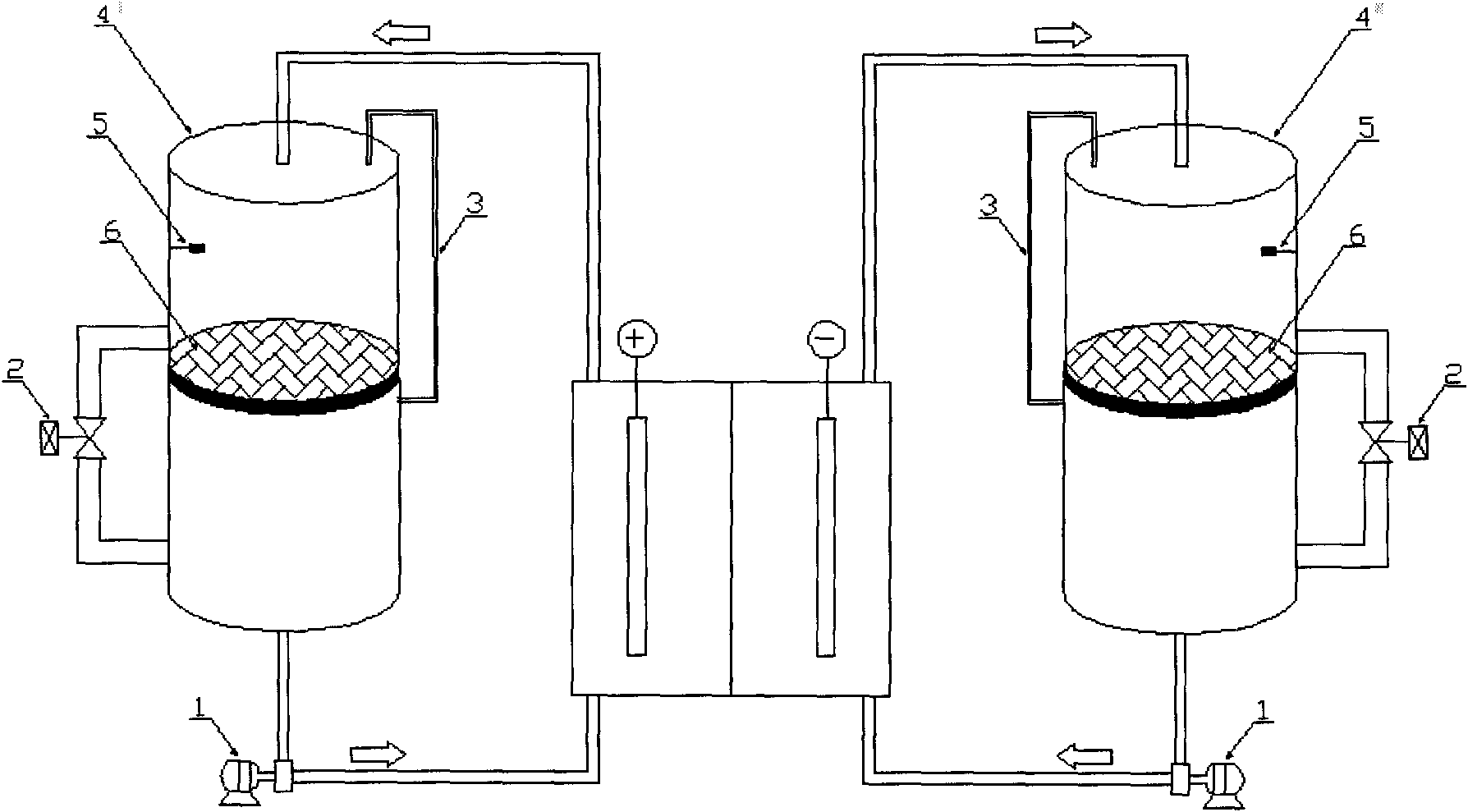

Embodiment 1

[0025] This redox flow battery system includes a flow battery or a flow battery pack, a positive electrolyte storage tank, and a negative electrolyte storage tank, and the positive electrolyte storage tank is separated into separate parts by a separator. Two spaces for storing electrolytes, and the space for storing electrolytes separated from each other are connected through pipelines, and valves are set on the connecting pipelines; one of the spaces for storing electrolytes is connected to the flow battery or liquid flow battery through pipelines. The positive electrode material inlet of the flow battery pack is connected, and another space for storing electrolyte is connected with the positive electrode material outlet of the flow battery or the flow battery pack through pipelines; Two open spaces for storing electrolyte, and the separate spaces for storing electrolyte are connected through pipelines, and valves are set on the connecting pipelines; one of the spaces for stor...

Embodiment 2

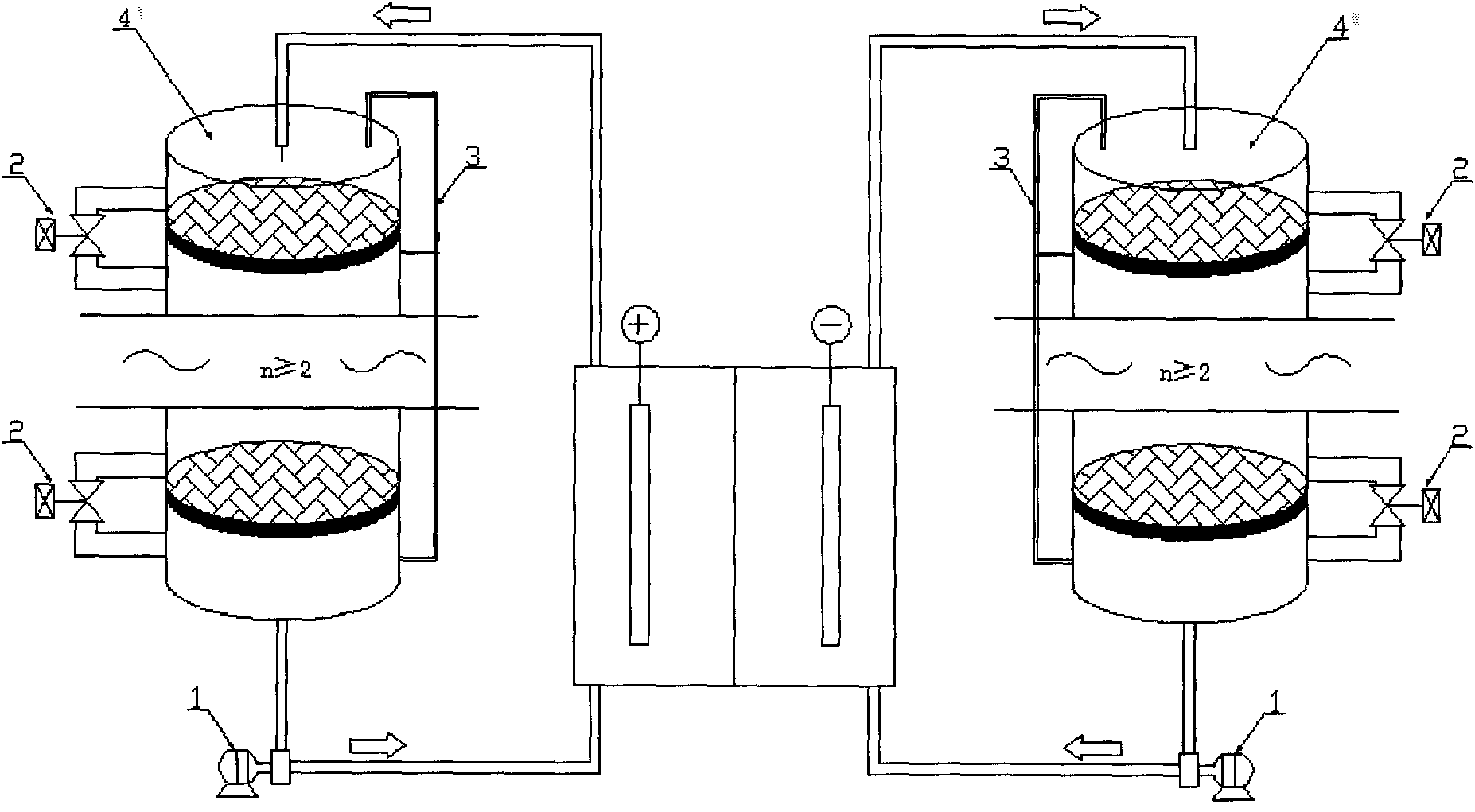

[0030] Such as figure 2 As shown, the difference with the structure of Embodiment 1 is that in this system structure, the number of spaces separated by each pole liquid storage tank is ≥ 3, and the conduction condition between each two spaces is the same as that of Embodiment 1. The difference The reason is that when two adjacent spaces are connected, the remaining spaces are in an isolated state. This operation mode can completely cut off the main circuit of the electrolyte during the charging and discharging process of the battery, avoiding the generation of leakage current.

Embodiment 3

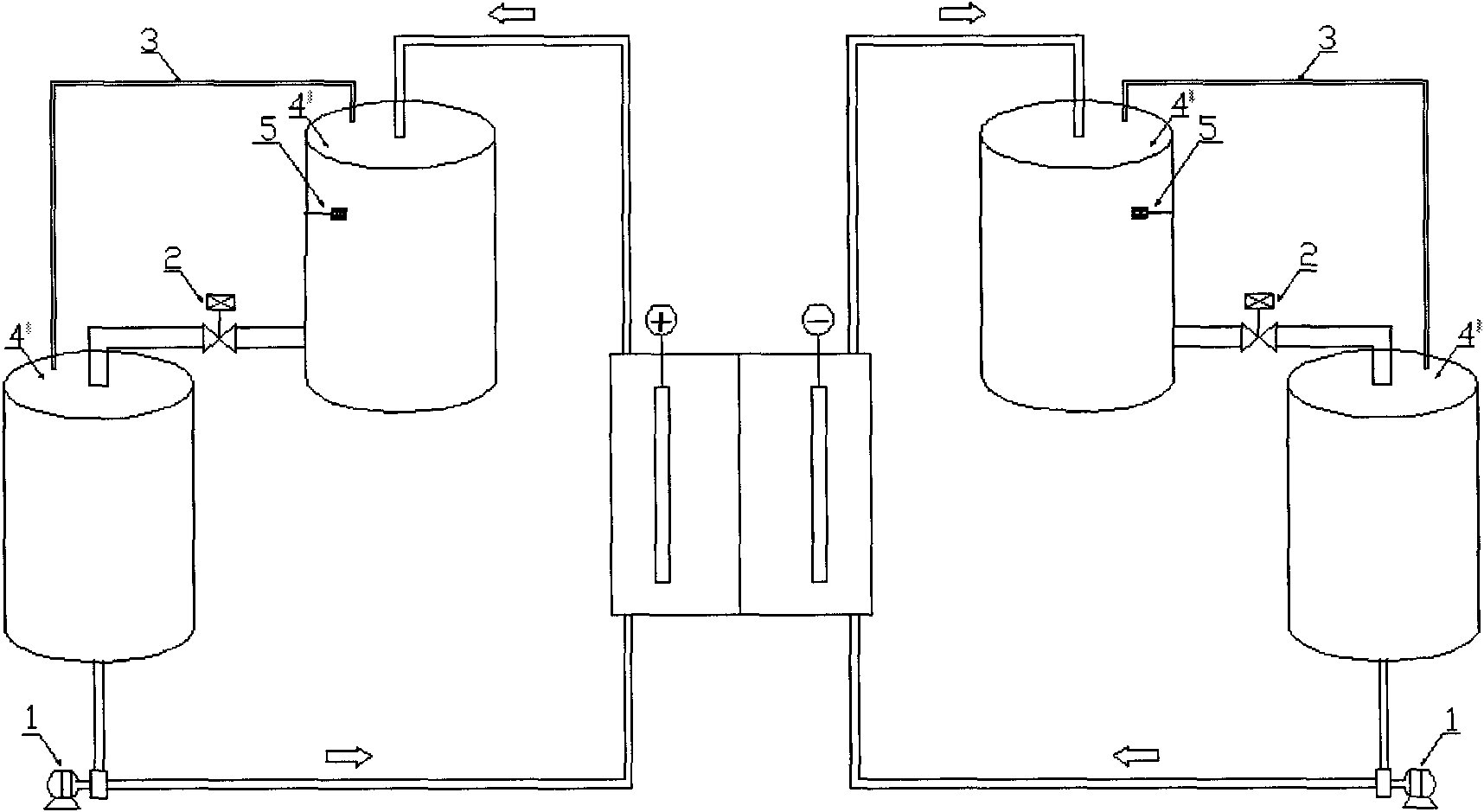

[0032] The specific system structure is composed of image 3 As shown, the difference with the structure of Embodiment 1 is that each pole in this system structure is composed of two liquid storage tanks, and there is a positioning difference when placed in space. When the liquid level meets the conduction condition in Embodiment 1 Valve 2 opens automatically, relies on the gravity field to automatically discharge, and the valve automatically closes after the discharge is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com