High-viscosity fuel preheating system for diesel engine

A diesel engine, high-viscosity technology, applied in the direction of fuel heat treatment device, charging system, engine starting, etc., can solve the problems of increased combustion unsafety, energy consumption, low heating efficiency, etc., and achieve improved combustion performance and emission performance , improved spray conditions, high seed oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The engine is intended to be a general diesel engine. The properties of jatropha oil are similar to those of diesel oil. It is possible to directly use jatropha oil on the diesel engine without changing the fuel supply system of the diesel engine. Oil runs as fuel.

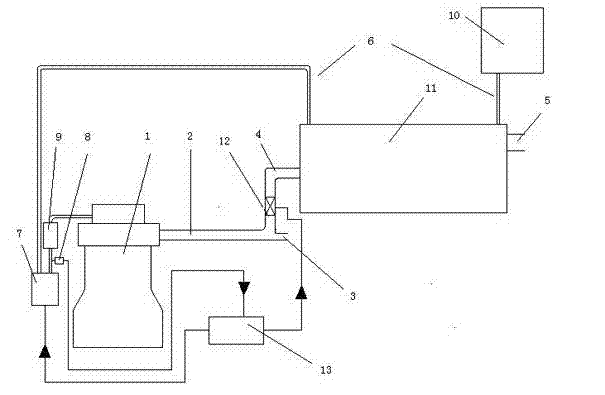

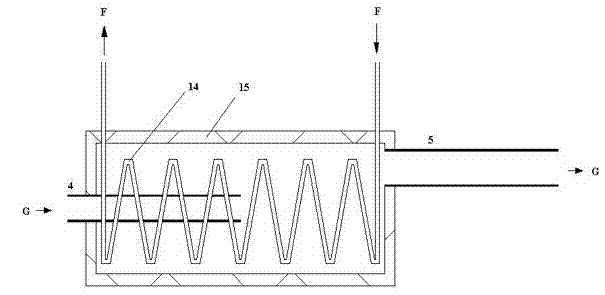

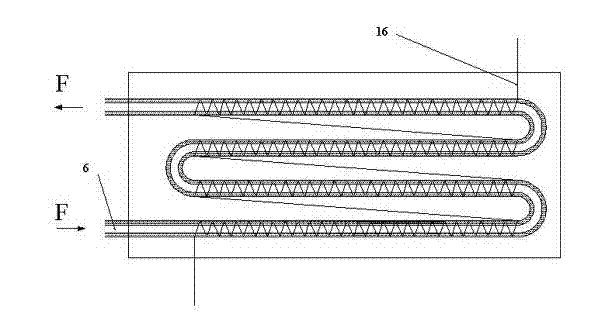

[0019] The exhaust gas temperature of the engine 1 is relatively high (generally 400°C to 650°C). During the exhaust process, with the upward movement of the engine piston, the engine 1 starts to exhaust, and the exhaust has a certain pressure. Under the condition that no fan is needed, the exhaust gas can enter the heat exchanger smoothly, which improves the efficiency of the whole system. The high-temperature exhaust gas in the engine 1 is discharged along the exhaust pipe 2. After being regulated by the exhaust control valve 12, a part of the exhaust gas enters the heat exchanger 11 along the heat exchanger intake pipe 4, and is discharged to the heat exchanger 11. After the high-viscosity jatropha oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com