Parabolic two-dimensional focusing X-ray compound refractive lens

A technology combining refractive lenses and paraboloids, applied in the application of diffraction/refraction/reflection for processing, etc., can solve the problems of insufficient manufacturing process accuracy, complex system design and adjustment, and large limitations on lens materials, and achieves the solution to the optical axis. Effects of calibration, small material constraints, improved focus and imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

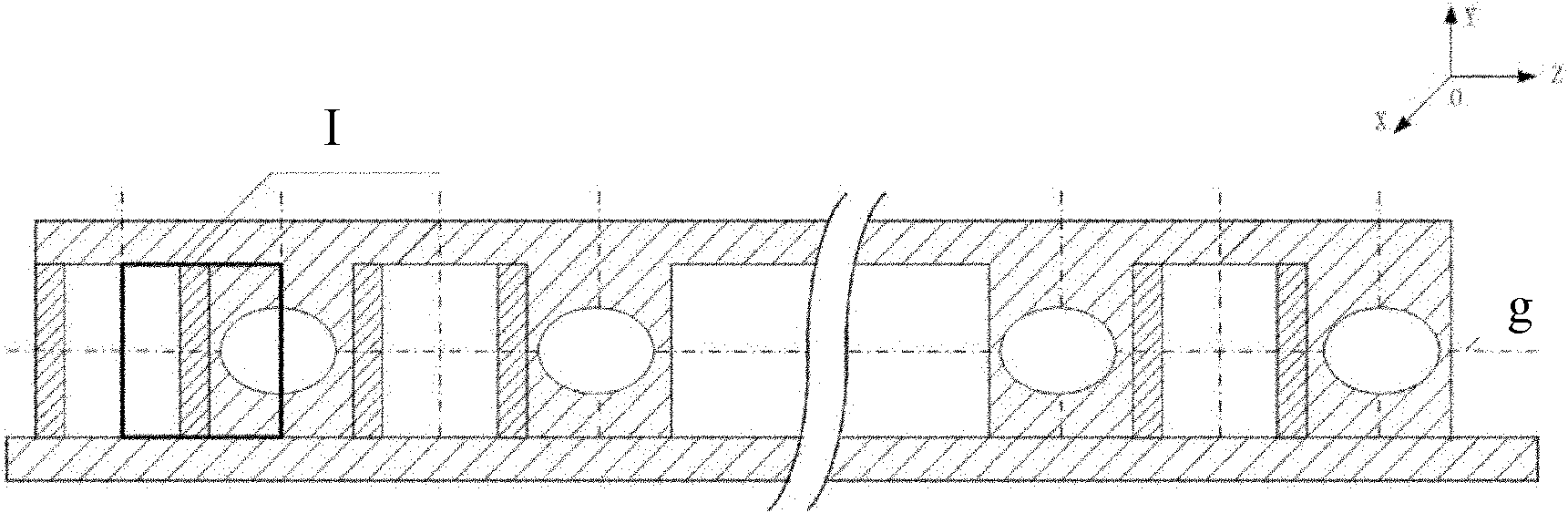

[0039] refer to Figure 1a ~ Figure 2d , in this embodiment, the thickness of the glass substrate is 2 millimeters, and the thickness of the clamping arm is 100 microns.

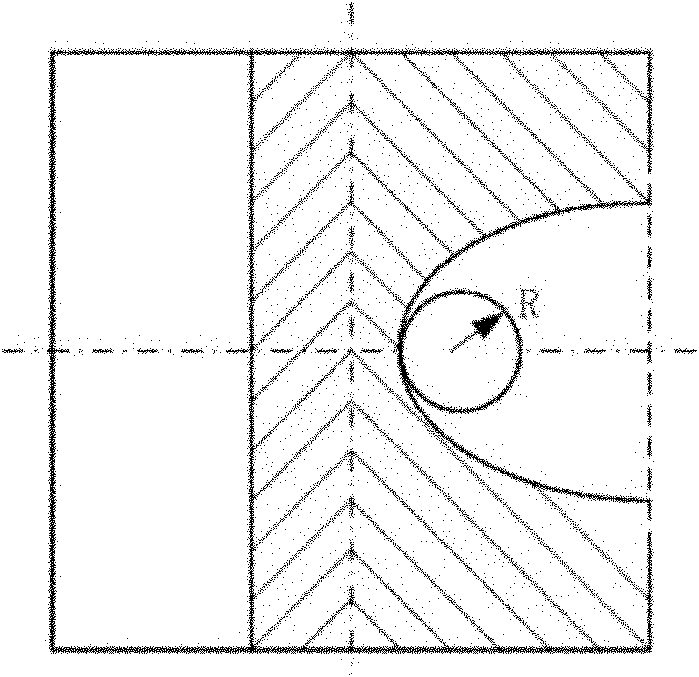

[0040] The long axis of the first parabolic cavity on the master mirror body is 242 microns, the short axis is 222 microns, and the center line of the first parabolic cavity is along the Figure 2a The y-axis direction of the coordinate system shown; the first parabolic cavity and the square cavity on the mother mirror are arranged in sequence according to the order of a first parabolic cavity followed by a square cavity, and the first parabolic cavity The shape cavity and the square cavity are coaxial along the z-axis of the coordinate system, and there are 100 square cavities; the length and width of the square cavity are 252 microns, and the height is 250 microns. The y-axis direction of the system; Figure 2a In the xoz section of the coordinate system shown, the distance between the center of the firs...

Embodiment 3

[0046] refer to Figure 1a ~ Figure 2d , in this embodiment, the thickness of the glass substrate is 1.8 mm, and the thickness of the clamping arm is 80 microns.

[0047] The long axis of the first parabolic cavity on the main body of the mother mirror is 200 microns, and the short axis is 180 microns, and the center line of the first parabolic cavity is along the Figure 2a The y-axis direction of the coordinate system shown; the first parabolic cavity and the square cavity on the mother mirror are arranged in sequence according to the order of a first parabolic cavity followed by a square cavity, and the first parabolic cavity Shaped cavities and square cavities are coaxial along the z-axis of the coordinate system, and there are 60 square cavities; the length and width of the square cavities are 211.5 microns, and the height is 210 microns. The y-axis direction of the system; Figure 2a In the xoz section of the coordinate system shown, the distance between the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com