IGBT with current carrier storage layer and additional hole passage

A carrier storage and hole technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of overvoltage shock resistance, low anti-interference, high internal resistance of high-voltage IGBTs, and harsh environmental conditions, etc., to achieve optimal circulation Effects of path, opening prevention, safe work area expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

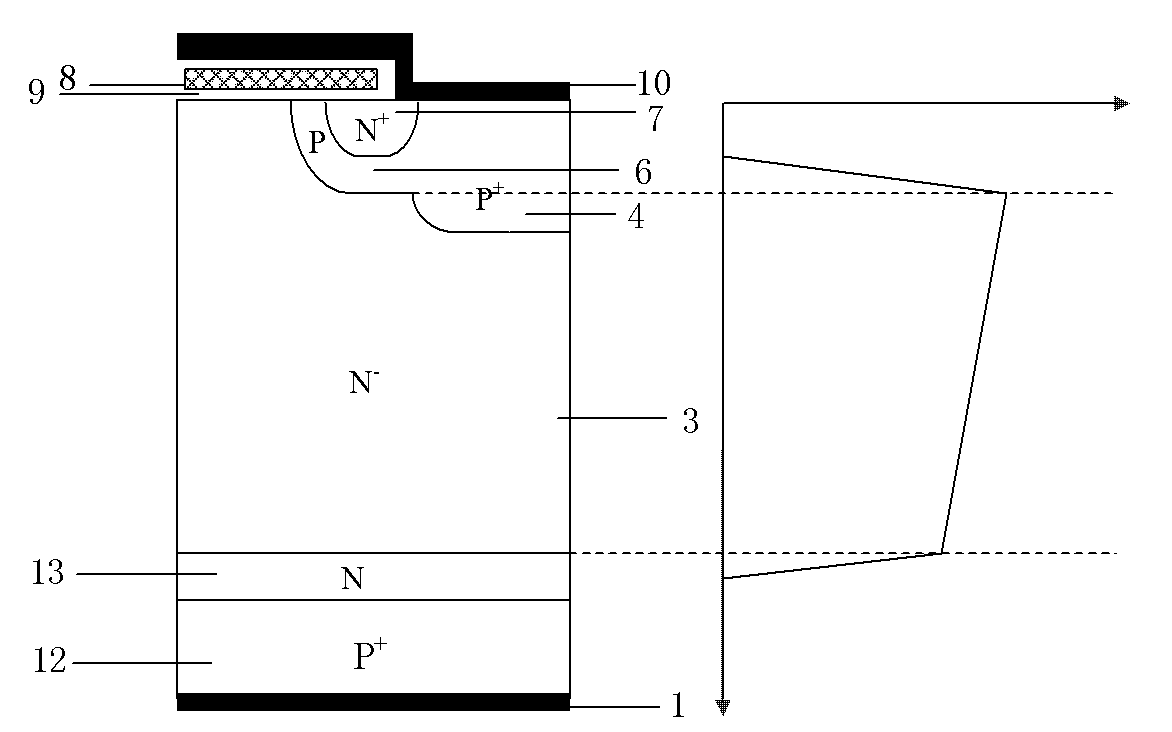

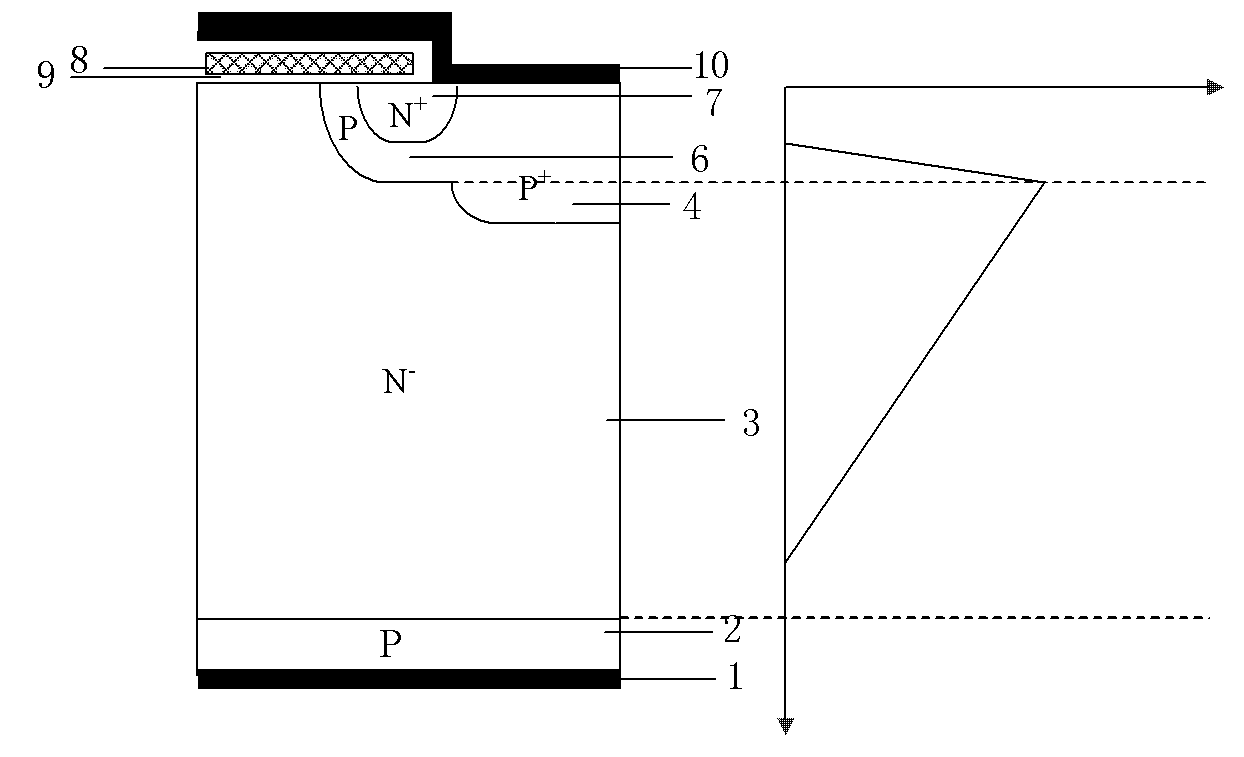

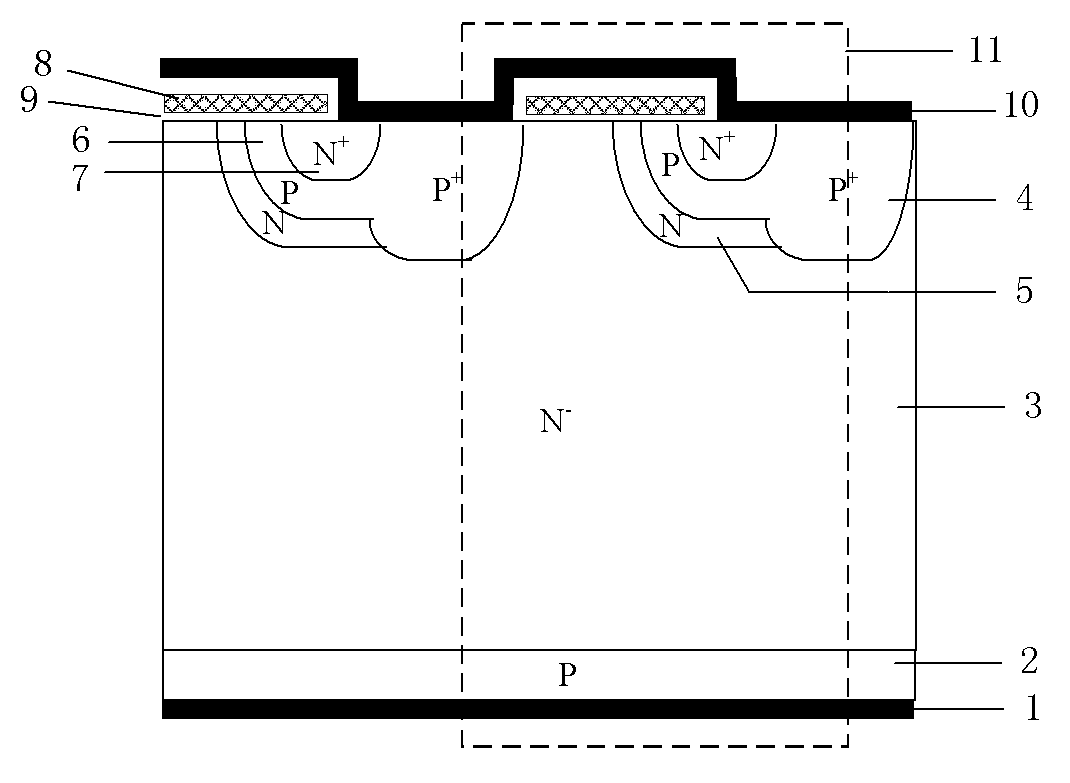

[0032] An IGBT with a carrier storage layer and an additional hole path, such as image 3 As shown, its single cell includes metallized collector electrode 1 on the back of P-type collector region 2, P-type collector region 2, N - Drift zone 3; including those located at N - The top of the drift region 3, the N part in contact with both the metallized emitter 10 and the gate oxide layer 9 + type source region 7, which is in contact with the gate oxide layer 9 and half surrounds the N + The P-type base region 6 of the source region 7; also includes the N-type carrier storage layer 5 that is in contact with the gate oxide layer 9 and half surrounds the P-type base region 6; also includes a P + body region 4, the P + The body region 4 is located below the metallized emitter 10, and the metallized emitter 10, N + Type source region 7, P type base region 6, N type carrier storage layer 5 and N type - P + body region 4; the P + The volume of body region 4 and N + The sum of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com