Mesoporous material coating based open-tubular capillary chromatographic column and preparation method thereof

A mesoporous material and capillary technology, applied in the field of chromatographic columns, can solve the problems of limited development, small column capacity, cumbersome preparation process, etc., and achieve the effect of increasing phase and column capacity, simple preparation process, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

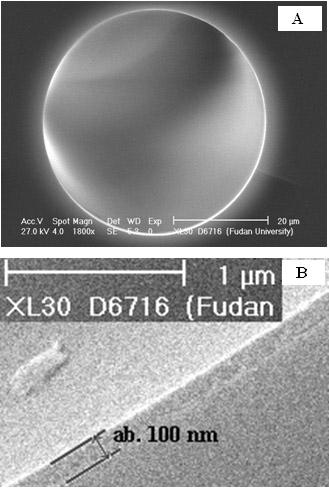

[0019] Example 1 Preparation and Characterization of Open-Tube Chromatographic Column

[0020] 1 mol / L sodium hydroxide, distilled water, 1 mol / L hydrochloric acid, and distilled water rinse the quartz capillary with an inner diameter of 50 μm (54 cm long) for 1 h each, 120 o The capillary was dried under nitrogen atmosphere for 1 h.

[0021] Dissolve 0.16 g of surfactant P123 in 2 mL of ethanol, then add 360 microliters of TEOS, 72 microliters of C8-TEOS, and finally add 250 microliters of water and 35 microliters of 1mol / L hydrochloric acid, 60 o C was heated and stirred for 1 h to obtain a sol.

[0022] The sol was poured into the treated quartz capillary by pressure, and left at room temperature for 10 min, 120 o Nitrogen under C drives away the unreacted sol, 120 o C continued to pass nitrogen gas for 1 h to complete the reaction. Surfactant was removed by ethanol-concentrated hydrochloric acid solution (20%, V / V) for 12 h. The concentrated hydrochloric acid solutio...

Embodiment 2

[0024] Example 2 Preparation and Characterization of Open-Tube Chromatographic Column

[0025] 1 mol / L sodium hydroxide, distilled water, 1 mol / L hydrochloric acid, and distilled water rinse the quartz capillary with an inner diameter of 25 μm (54 cm long) for 1 h each, 120 o The capillary was dried under nitrogen atmosphere for 1 h.

[0026] Dissolve 0.16 g of surfactant F127 in 2 mL of ethanol, then add 360 microliters of TEOS, 72 microliters of C8-TEOS, and finally add 250 microliters of water and 35 microliters of 1mol / L hydrochloric acid, 60 o C was heated and stirred for 1 h to obtain a sol.

[0027] The sol was poured into the treated quartz capillary by pressure, and left at room temperature for 10 min, 120 o Nitrogen under C drives away the unreacted sol, 120 o C continued to pass nitrogen gas for 1 h to complete the reaction. Surfactant was removed by ethanol-concentrated hydrochloric acid solution (20%, V / V) for 12 h.

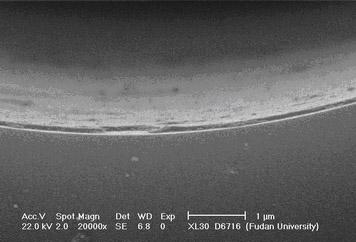

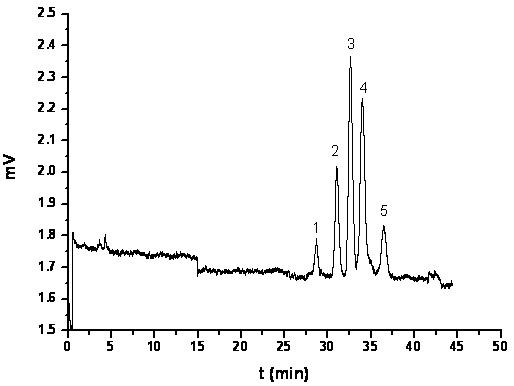

[0028] The resulting open-tubular column...

Embodiment 3

[0029] Example 3 Preparation and Characterization of Open-Tube Chromatographic Column

[0030] 1 mol / L sodium hydroxide, distilled water, 1 mol / L hydrochloric acid, and distilled water rinse the quartz capillary with an inner diameter of 50 μm (54 cm long) for 1 h each, 120 o The capillary was dried under nitrogen atmosphere for 1 h.

[0031] Dissolve 0.16 g of surfactant P123 in 2 mL of ethanol, then add 360 microliters of TEOS, 72 microliters of 3-aminopropyltriethoxysilane, and finally add 250 microliters of water and 35 microliters 1mol / L hydrochloric acid, 60 o C was heated and stirred for 1 h to obtain a sol.

[0032] The sol was poured into the treated quartz capillary by pressure, and left at room temperature for 10 min, 120 o Nitrogen under C drives away the unreacted sol, 120 o C continued to pass nitrogen gas for 1 h to complete the reaction. Surfactant was removed by ethanol-concentrated hydrochloric acid solution (20%, V / V) for 12 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com