Modified polyvinylidene fluoride (PVDF) hollow fibrous membrane and preparation method thereof

A polyvinylidene fluoride and fiber membrane technology, which is applied in chemical instruments and methods, membrane technology, and semi-permeable membrane separation, can solve problems such as dynamic membrane instability, achieve low membrane fouling growth rate, improve hydrophilicity and The effect of anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a modified polyvinylidene fluoride (PVDF) hollow fiber membrane, comprising the steps of:

[0037] (1), PVDF hollow fiber microfiltration membrane pretreatment

[0038] The PVDF hollow fiber microfiltration membrane with a membrane pore size of 0.05 μm is made into an MBR module, and then the membrane module is soaked in deionized water to wash off the glycerin on the surface of the membrane, and it is pre-pressed at a temperature of 20°C and a pressure of 0.1MPa for 1 hour before use. ;

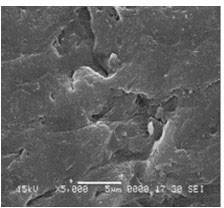

[0039] Figure 1a It is the SEM picture of the surface of the unmodified PVDF hollow fiber microfiltration membrane after pretreatment;

[0040] (2), TiO 2 Dynamically modified membrane preparation

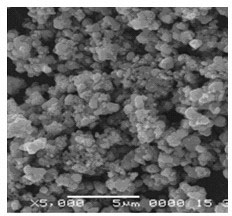

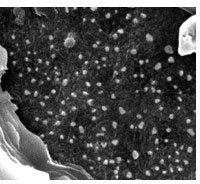

[0041] Place the pretreated hollow fiber microfiltration membrane module in TiO with an average particle size of 50nm and a concentration of 0.1%. 2 Ultrasonic treatment at room temperature for 2 minutes in the water suspension, then standing in the air, after n...

Embodiment 2

[0049] A method for preparing a modified polyvinylidene fluoride (PVDF) hollow fiber membrane, comprising the steps of:

[0050] (1) PVDF hollow fiber microfiltration membrane pretreatment

[0051] The PVDF hollow fiber microfiltration membrane with a membrane pore size of 0.10 μm is made into an MBR module, and the membrane module is soaked in deionized water to wash off the glycerin on the surface of the membrane, and it is pre-pressed at a temperature of 25 ° C and a pressure of 0.05 MPa for 1.5 hours before use. ;

[0052] (2) TiO 2 Dynamically modified membrane preparation

[0053] Put the pretreated hollow fiber microfiltration membrane module in 1.0%TiO 2 (TiO 2 The water suspension of nanoparticles with an average particle size of 100nm) is first subjected to ultrasound for 10 minutes, then left to stand in the air and dried, and then press-filtered. During the press-filtering process, the pressure is controlled at 0.50Mpa and the time is 1.0h to form an irreversib...

Embodiment 3

[0060] A method for preparing a modified polyvinylidene fluoride (PVDF) hollow fiber membrane, comprising the steps of:

[0061] (1), PVDF hollow fiber microfiltration membrane pretreatment

[0062] The PVDF hollow fiber microfiltration membrane with a membrane pore size of 0.2 μm is made into an MBR module, and the membrane module is soaked in deionized water to wash away the glycerol on the surface of the hollow fiber microfiltration membrane, and pre-pressed at a temperature of 30°C and a pressure of 0.5MPa Standby after 1.0h;

[0063] (2) TiO 2 Dynamically modified membrane preparation

[0064] Put the pretreated hollow fiber microfiltration membrane module in 0.8%TiO 2 (TiO 2 Nanoparticles with an average particle size of 200nm) were first subjected to ultrasonication for 15 minutes, then left to stand in the air, and after being dried, the pressure was controlled at 0.20Mpa, and the pressure was filtered for 4 hours to form an irreversible dynamic deposition layer; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com