Preparation method for highly-efficient nickel-graphite powder and special device

A graphite powder, graphite powder technology, applied in coating, fusion spraying, metal material coating process and other directions, can solve the problem that the coating coverage and coating thickness cannot be controlled more accurately, and a large amount of waste water and waste liquid cannot be realized. production and other problems, to achieve the effect of prolonging the coating reaction time, increasing the coverage rate, improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

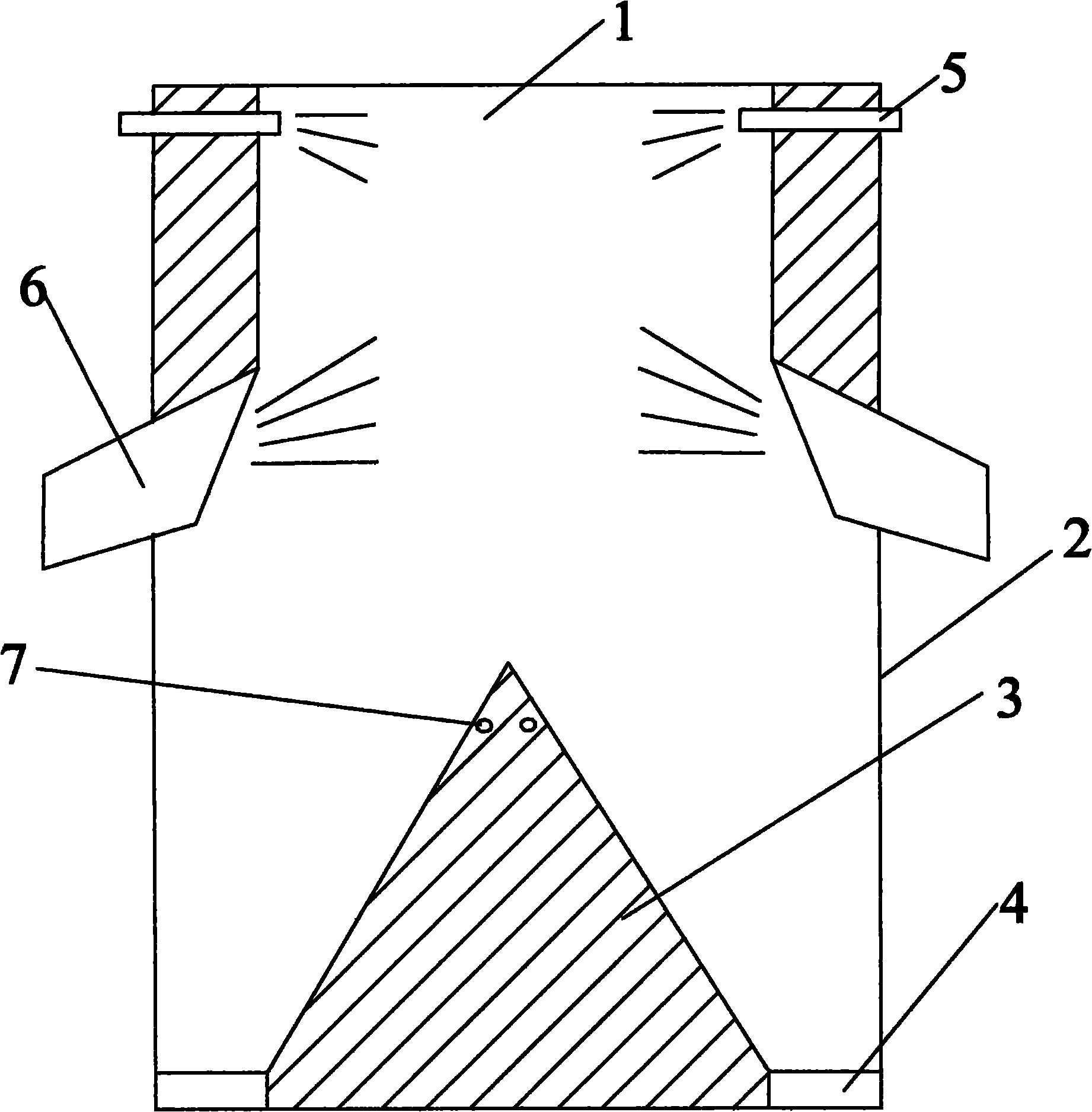

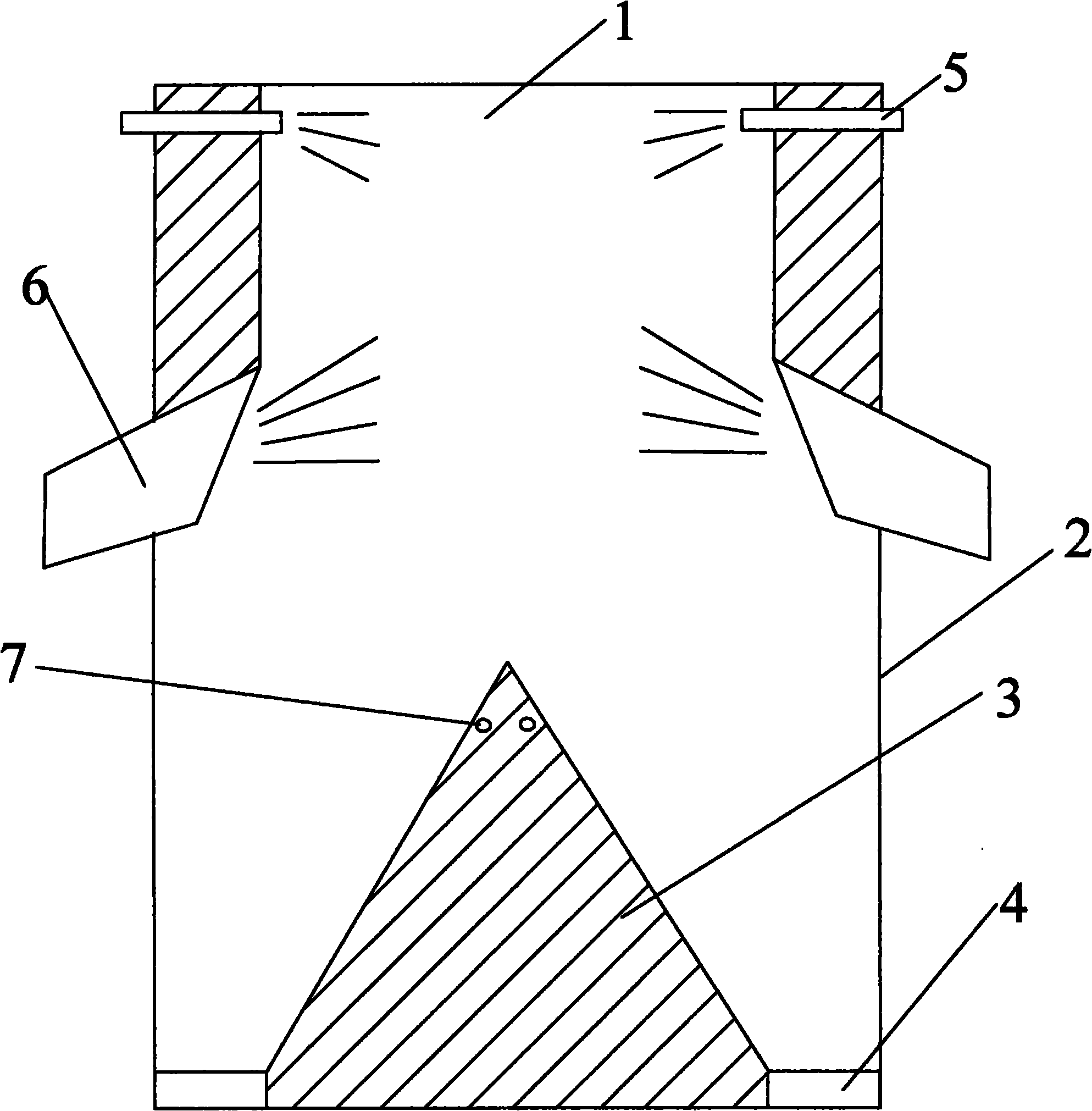

[0050] Example: see figure 1 , the preparation method of a kind of efficient nickel-graphite powder provided by the invention, comprises the following steps:

[0051] (1) Prepare the reaction device:

[0052] Prepare a cylindrical airtight container 1, its interior is hollow, as graphite powder nickel plating reaction space;

[0053] A plurality of powder injection ports 5 are arranged on the upper part of the side wall 2 of the container, and the powder injection ports 5 are connected to a powder feeding device;

[0054] At least one arc injection port 6 is arranged in the middle part of the side wall 2 of the container, and an arc injection gun and a compressed air gun are arranged in the injection port 6. What this embodiment adopts is a high-pressure nitrogen gun;

[0055] A pressure valve 4 for gas and powder discharge is arranged at the bottom of the container 1; what this embodiment adopts is an automatic one-way single-opening pressure valve, which only opens from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com