Recycle system and recycle method of coked wastewater

A technology of coking wastewater and treatment methods, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve difficult and high-cost problems, reduce treatment costs, improve The effect of wastewater recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

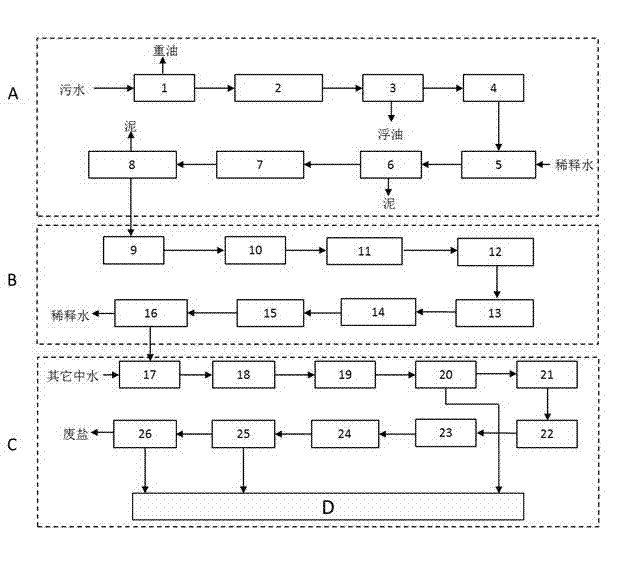

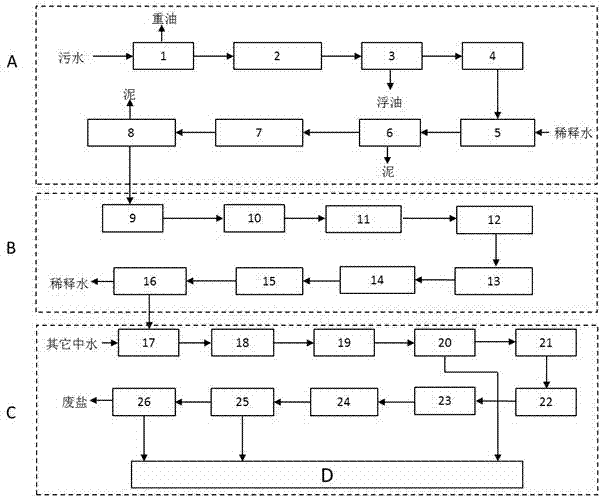

[0031] Example 1: After 280 t / h of coking wastewater is biochemically treated in the biochemical treatment section A, it is mixed with concentrated water and backwash water 28 t / h from the ultrafiltration equipment 12 in the advanced treatment section B in the coagulation reaction tank 7 Then directly enter the advanced treatment section B. Part of the effluent from the advanced treatment section B is sent to the A / O / O reaction tank 5 as dilution water, and the other part (about 110 t / h) directly enters the reclaimed water reuse section C. Reclaimed water such as advanced treatment effluent, circulating water effluent, desalination station reverse osmosis concentrated water, boiler effluent, etc. is mixed in the regulating tank 17 of reclaimed water reuse section C. After the mixed solution is subjected to lime + flocculation sedimentation and multi-media filtration, about 200 t / h of water is directly discharged to the circulating water system D, and the remaining about 100 t / ...

Embodiment 2

[0032] Example 2: After 280 t / h of coking wastewater is biochemically treated in the biochemical treatment section A, it is mixed with concentrated water and backwash water 28 t / h from the ultrafiltration equipment 12 in the advanced treatment section B in the coagulation reaction tank 7 Then directly enter the advanced treatment section B. Part of the water produced in the advanced treatment section B is sent to the A / O / O reaction tank 5 as dilution water, and the other part (about 110 t / h) directly enters the reclaimed water reuse section C. Reclaimed water such as advanced treatment effluent, circulating water effluent, desalination station reverse osmosis concentrated water, boiler effluent, etc. is mixed in the regulating tank 17 of reclaimed water reuse section C. After the mixed solution is subjected to lime + flocculation sedimentation and multi-media filtration, about 200 t / h of water is directly discharged to the circulating water system D, and the remaining about 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com