Pressure-sensitive material and preparation method thereof

A technology of pressure-sensitive materials and ball abrasives, applied in the field of pressure-sensitive materials and their preparation, can solve the problems of reducing sintering temperature, high sintering temperature, and reducing leakage current, so as to save energy, improve pressure-sensitive characteristics, and reduce leakage current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

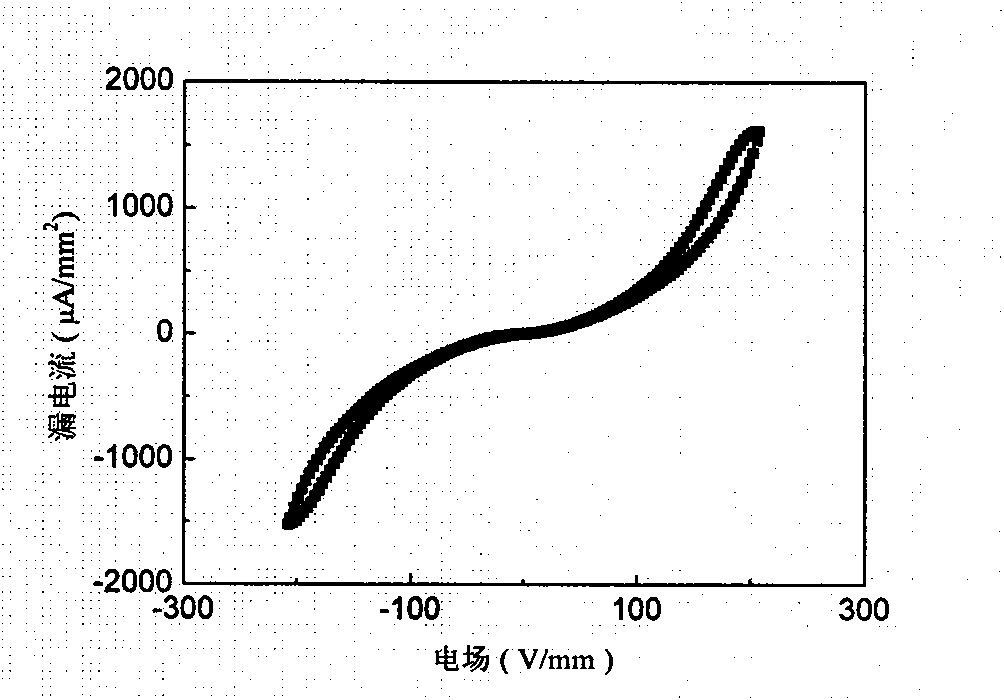

Embodiment 1

[0018] 1. Choose CaCu whose quality is more than 98% 3 Ti 4 o 12 Powder and mass are more than 98% CuO-Bi 2 o 3 -B 2 o 3 Glass powder, CuO-Bi 2 o 3 -B 2 o 3 Glass powder added to CaCu 3 Ti 4 o 12 In powder, CuO-Bi 2 o 3 -B 2 o 3 The amount of glass powder added is CaCu 3 Ti 4 o 12 17% of powder mass.

[0019] 2. Put the prepared materials in step (1) into a ball mill and mix them evenly to obtain a ball mill.

[0020] 3. Add the ball mill, deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder into the ball mill and mix again, of which: the amount of deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder They are 17%, 1.2%, and 6% of the mass of the ball abrasive, and they are required to be mixed evenly; airflow spray granulation is used to obtain powder particles with a particle diameter of 0.001 to 1 mm.

[0021] 4. Put the powder particles obtained in step (3) into a press and press into a ceramic g...

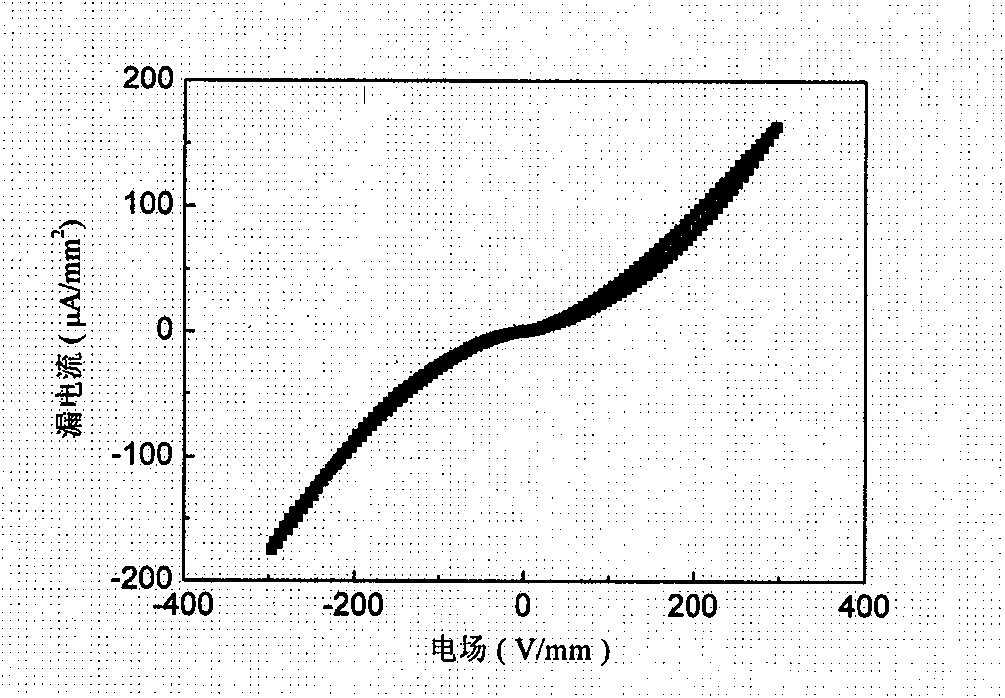

Embodiment 2

[0026] 1. Choose CaCu whose quality is more than 98% 3 Ti 4 o 12 Powder and mass are more than 98% CuO-Bi 2 o 3 -B 2 o 3 Glass powder, CuO-Bi 2 o 3 -B 2 o 3 Glass powder added to CaCu 3 Ti 4 o 12 In powder, CuO-Bi 2 o 3 -B 2 o 3 The amount of glass powder added is CaCu 3 Ti 4 o 12 10% of powder mass.

[0027] 2. Put the prepared materials in step (1) into a ball mill and mix them evenly to obtain a ball mill.

[0028] 3. Add the ball mill, deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder into the ball mill and mix again, of which: the amount of deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder They are 40%, 3%, and 11% of the mass of the ball abrasive, and they are required to be mixed evenly; airflow spray granulation is used to obtain powder particles with a particle diameter of 0.001-1 mm.

[0029] 4. Put the powder particles obtained in step (3) into a press and press into a ceramic green...

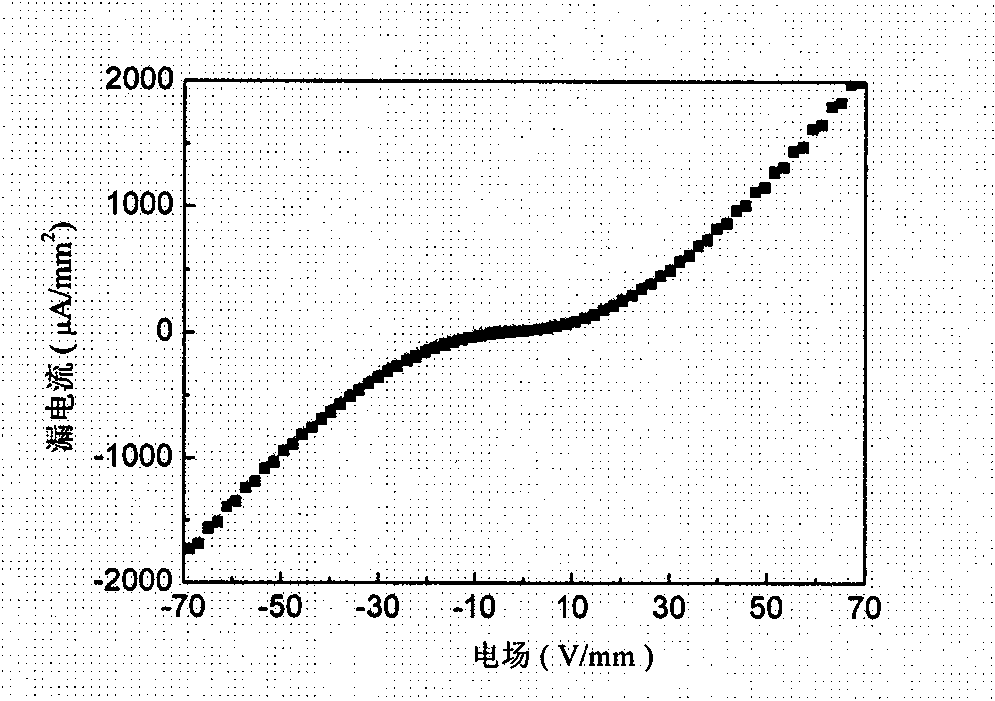

Embodiment 3

[0034] 1. Choose CaCu whose quality is more than 98% 3 Ti 4 o 12 Powder and mass are more than 98% CuO-Bi 2 o 3 -B 2 o 3 Glass powder, CuO-Bi 2 o 3 -B 2 o 3 Glass powder added to CaCu 3 Ti 4 o 12 In powder, CuO-Bi 2 o 3 -B 2 o 3 The amount of glass powder added is CaCu 3 Ti 4 o 12 1% of powder mass.

[0035] 2. Put the prepared materials in step (1) into a ball mill and mix them evenly to obtain a ball mill.

[0036] 3. Add the ball mill, deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder into the ball mill and mix again, of which: the amount of deionized water, polyacrylic acid ammonia dispersant and polyvinyl alcohol binder They are 15%, 0.2%, and 5% of the mass of the ball abrasive respectively, and they are required to be mixed evenly; airflow spray granulation is used to obtain powder particles with a particle diameter of 0.001-1 mm.

[0037] 4. Put the powder particles obtained in step (3) into a press and press into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com