Photobioreactor for culturing microorganisms

A photobioreactor, photosynthetic microorganism technology, applied in photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve the difficulty of tube wall cleaning, reactor cost and High operating cost, infection, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

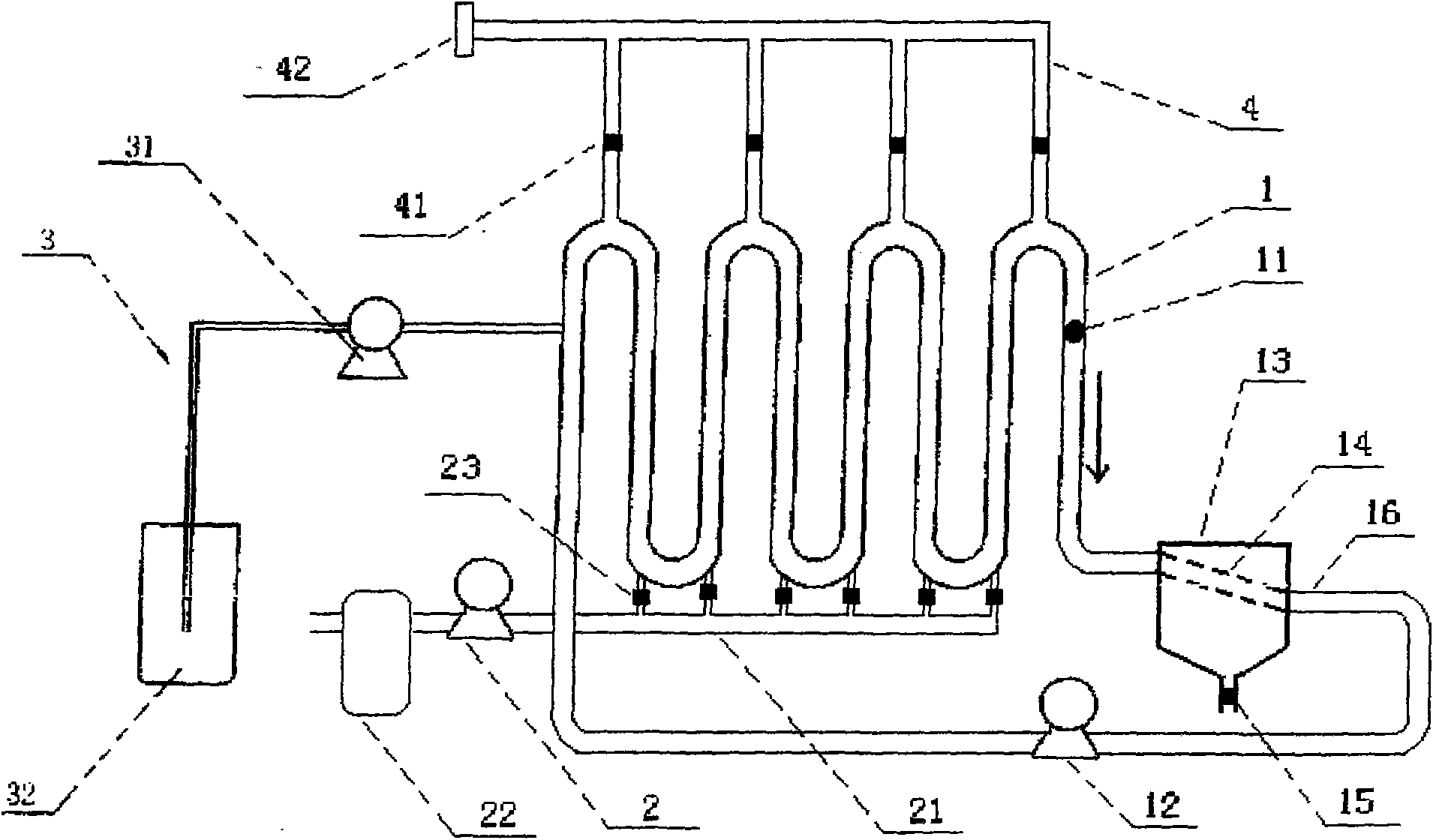

[0018] Embodiment one: see attached figure 1 .

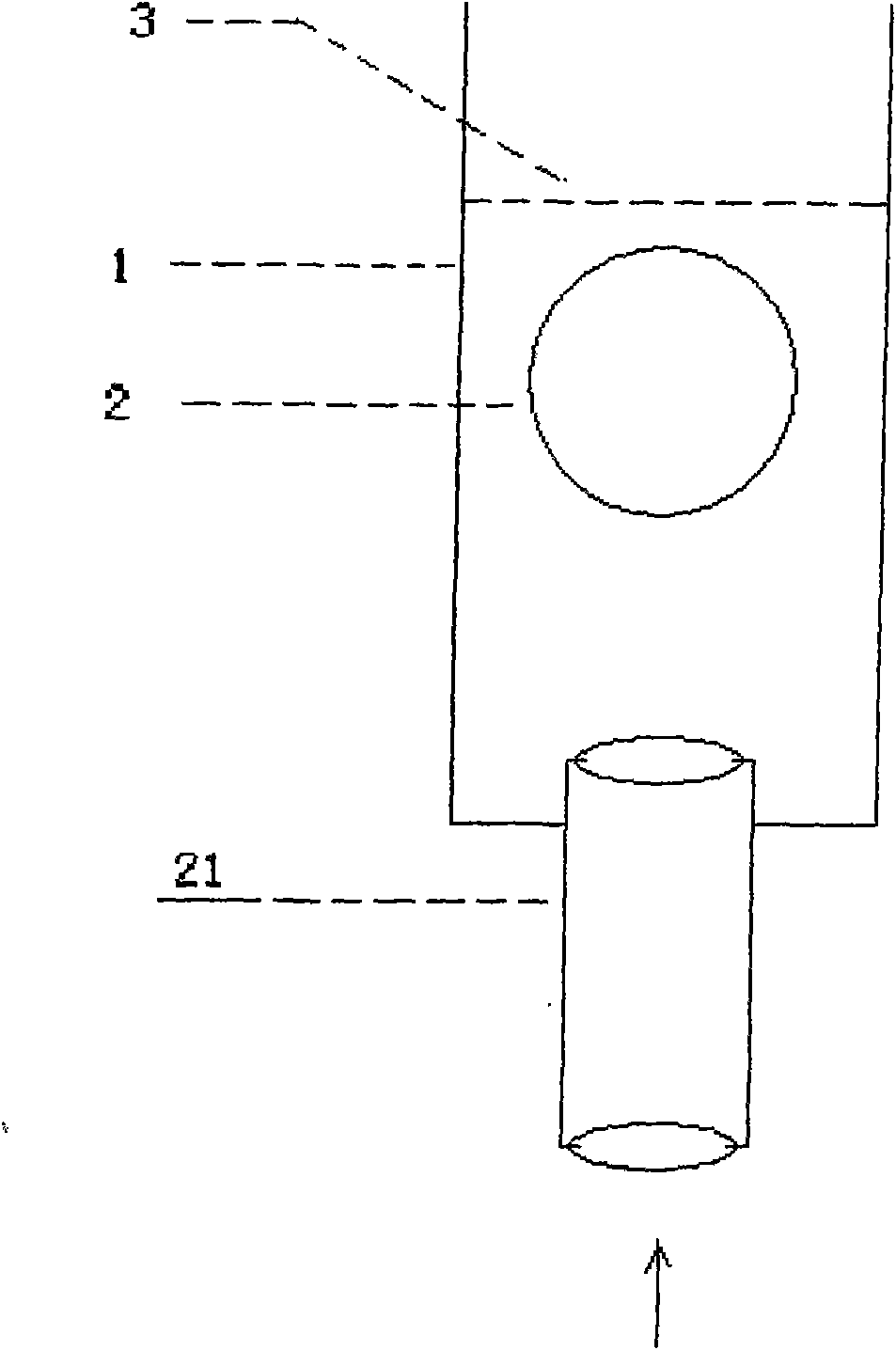

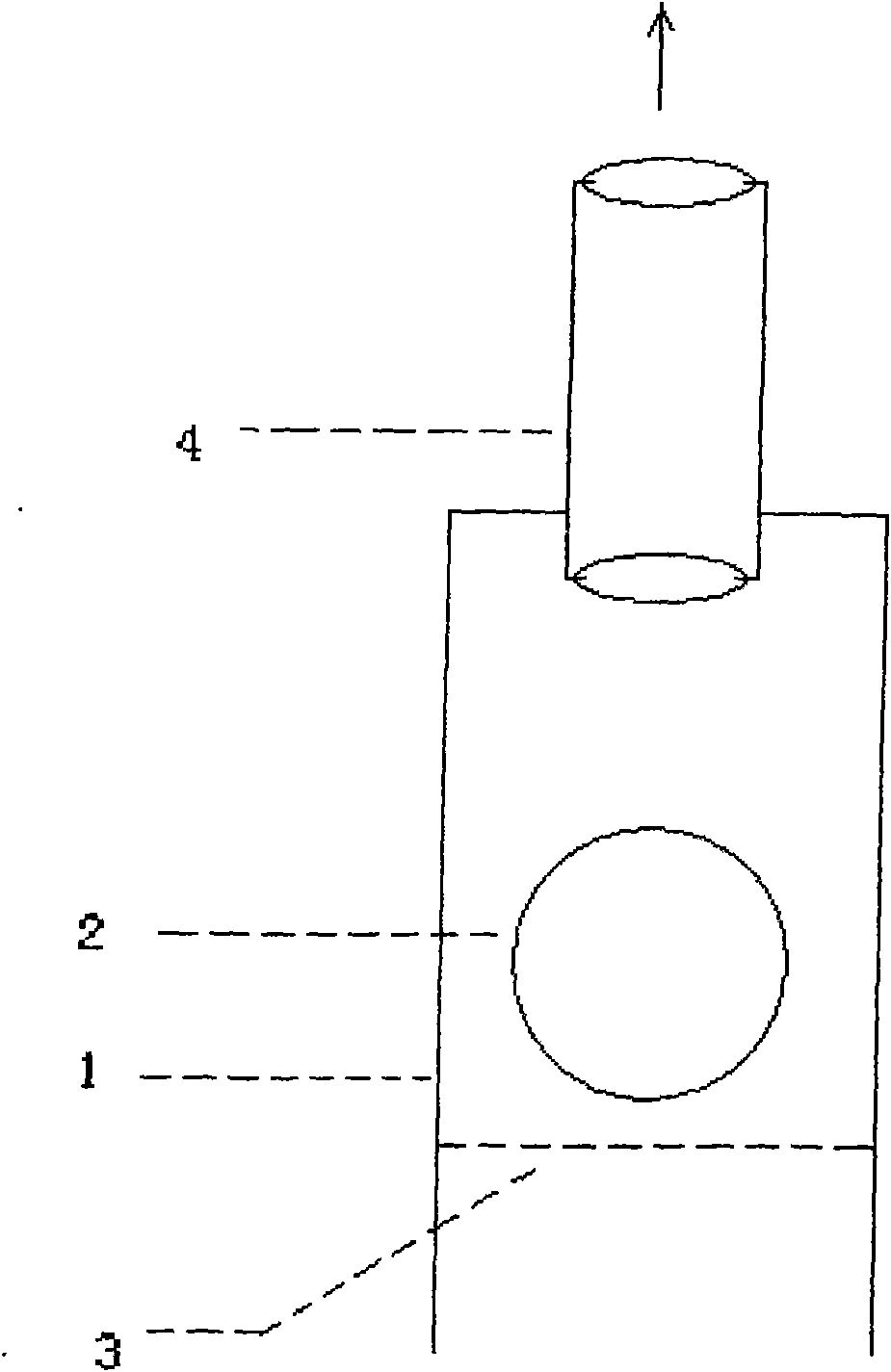

[0019] Preferably several "S" shaped glass hollow pipes 1 are connected in series with the pump 12, the algae liquid settlement tank 13, and the connecting conduit 16 to form a circulation pipe, and the "S" shaped pipe 1 is erected or obliquely arranged on a fixed frame (not shown), Built-in at least one spherical piston 11 made of sponge (its diameter is roughly equal to the inner diameter of the circulation pipeline), the pump 12 is preferably a screw pump, and the gas required by the algae liquid passes through the purification device 22, the air pump 2, the intake pipe 21, and the sinking ball type check The valve 23 enters the bottom of the "S"-shaped pipe, and the gas rises in the hollow pipe 1 to stir the culture solution and perform gas exchange. The exhaust gas is discharged through the exhaust pipe 4, and a float check valve 41 is installed on the exhaust pipe 4 to exhaust Isolation device 42 is installed at the mouth...

Embodiment 2

[0022] Embodiment 2: other structures are the same as Embodiment 1, the difference is that the perforated conduit 14 is canceled, a device is added at the water outlet end of the pump, and a plurality of pistons 11 are added one by one. Since the pistons do not pass through the pump, the pump can Choose from various types.

Embodiment 3

[0023] Embodiment 3: Other structures are the same as Embodiment 1, except that the pump is a peristaltic pump. Take Haematococcus pluvialls as an example to set forth the using method of above-mentioned embodiment below:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com