Lighting inspection device of organic EL display substrate and method thereof

A technology for lighting inspection and display panels, which is applied to instruments, electric solid-state devices, semiconductor devices, etc., can solve the problems of time-consuming and difficult to realize automation, and achieve the effect of ensuring luminous life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] Figure 9 It is a plan view of a main substrate on which dedicated wiring for power supply to pixels and electrode pads are formed according to an embodiment of the present invention. In the backplane process, when manufacturing the main substrate 320 on which the TFTs and wiring are made, in order to be able to supply power together in units of the main substrate, the electrode pads 305 for power supply to the gate portion and the power supply wiring for the gate portion are simultaneously fabricated on both sides of the substrate. Wire 306 , electrode pad 307 for source portion power supply, source portion power supply wiring 308 , EL element second electrode power supply pad 309 , EL element second electrode power supply wiring 310 . At the same time, other wiring required for panel lighting is produced. In addition, in the present embodiment, a structure in which power is supplied from both sides of the main substrate is adopted, but a structure in which power is s...

Embodiment 2

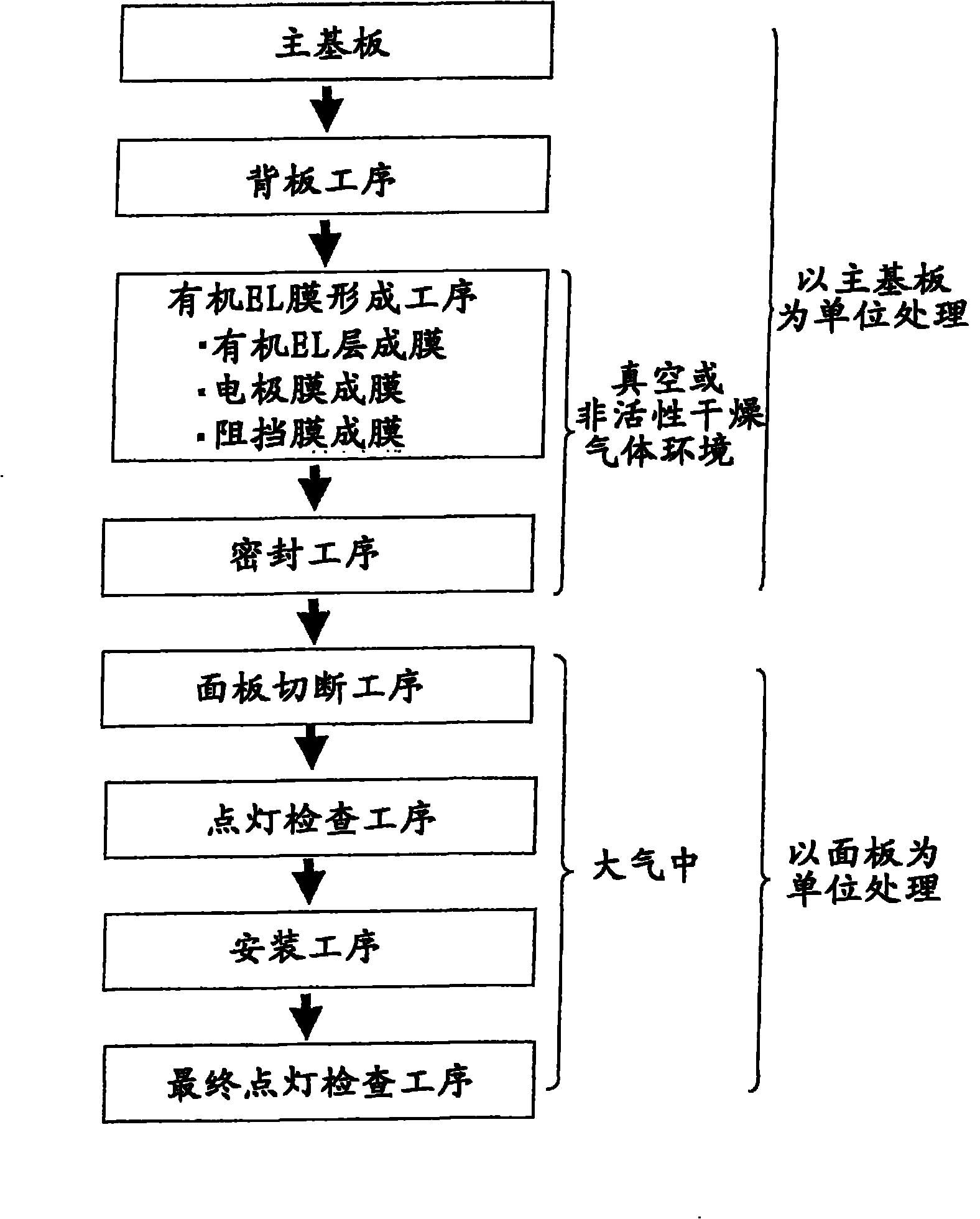

[0159] Figure 16 An example of the manufacturing process of the active-type organic EL panel when the lighting inspection and correction device according to the embodiment of the present invention is used is shown. with in figure 1 In the conventional process shown, the lighting inspection process is processed in units of panels, since the lighting inspection process can be performed in units of main substrates that have not undergone the sealing process, so it is easy to automate. In addition, regardless of the sealing structure of the panel , can take in the correction process that can correct pixel defects, so the yield rate of the panel with the resin sealing structure required in the large panel can be improved.

[0160] Figure 17 An example of the configuration of an organic EL display manufacturing system according to an embodiment of the present invention is shown. Here, an example in which the organic EL film forming process is performed by a vacuum film forming ...

Embodiment 3

[0164] In order to ensure the light-emitting life of the organic EL panel, in the inspection and correction equipment according to the embodiment of the present invention, the dew point is managed below -70°C by inert dry gas such as dry nitrogen. In order to easily manage the dew point and save the inert dry gas, It is desirable to minimize the space within the inspection and correction equipment. Since the inspection and correction device of this embodiment is an optical device, it uses a frame structure with a glass plate as a window, and by arranging the detection system and laser irradiation system outside the glass plate, it is possible to greatly reduce the consumption of the inert dry gas. space.

[0165] Figure 18 An example of a lighting inspection device that lowers the space 801 filled with inert dry gas is shown. The stage 805, the main substrate 320, and the probe 802 of the lighting inspection device 806 are connected to the transfer chamber 804, and are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com