Low-loss medium loaded surface plasmon excimer optical waveguide

A surface plasmon, dielectric loading type technology, applied in the field of optical waveguide, can solve the problems of unfavorable waveguide and device integration, increased transmission loss, long transmission distance, etc., and achieves the effect of size reduction, transmission loss reduction, and low transmission loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

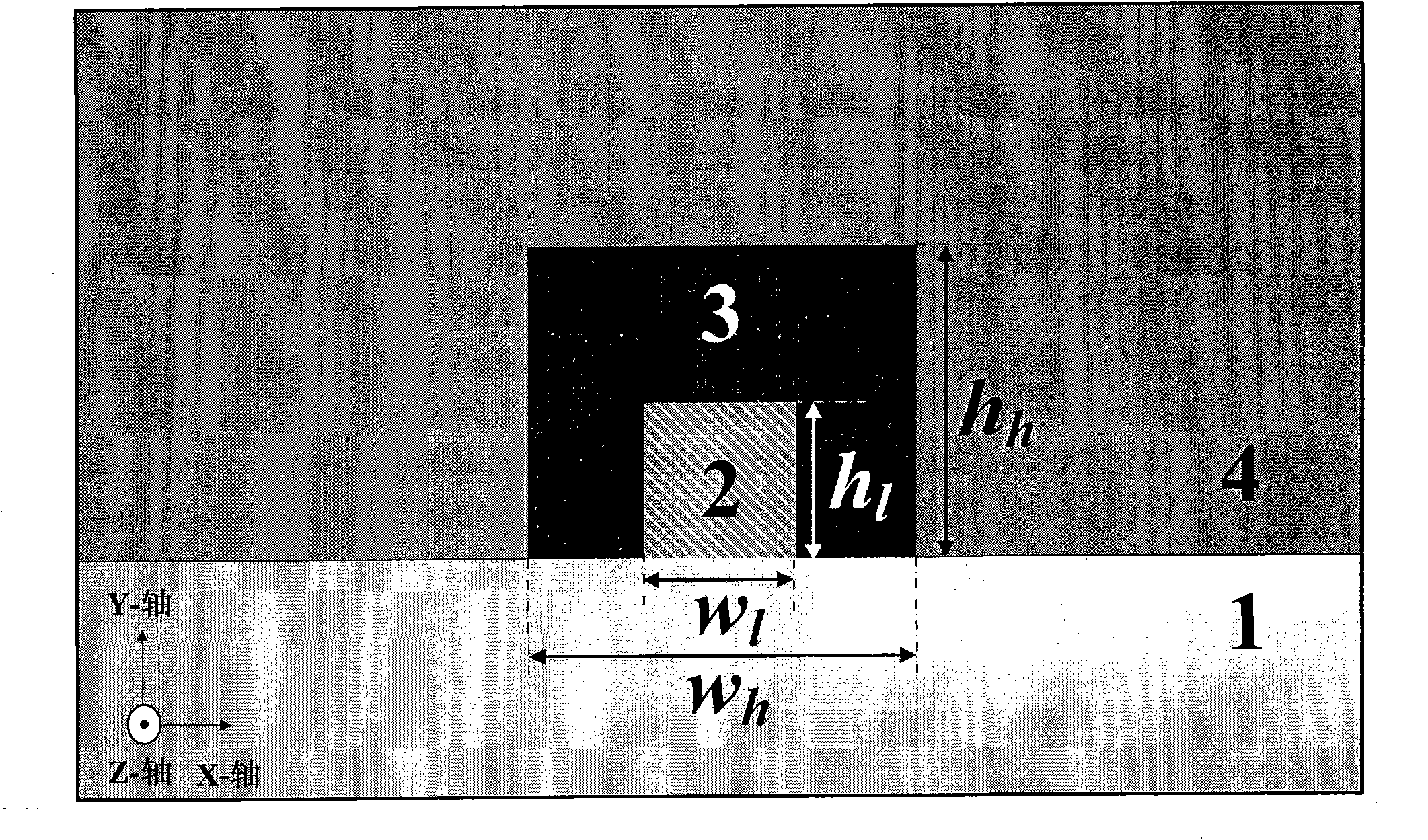

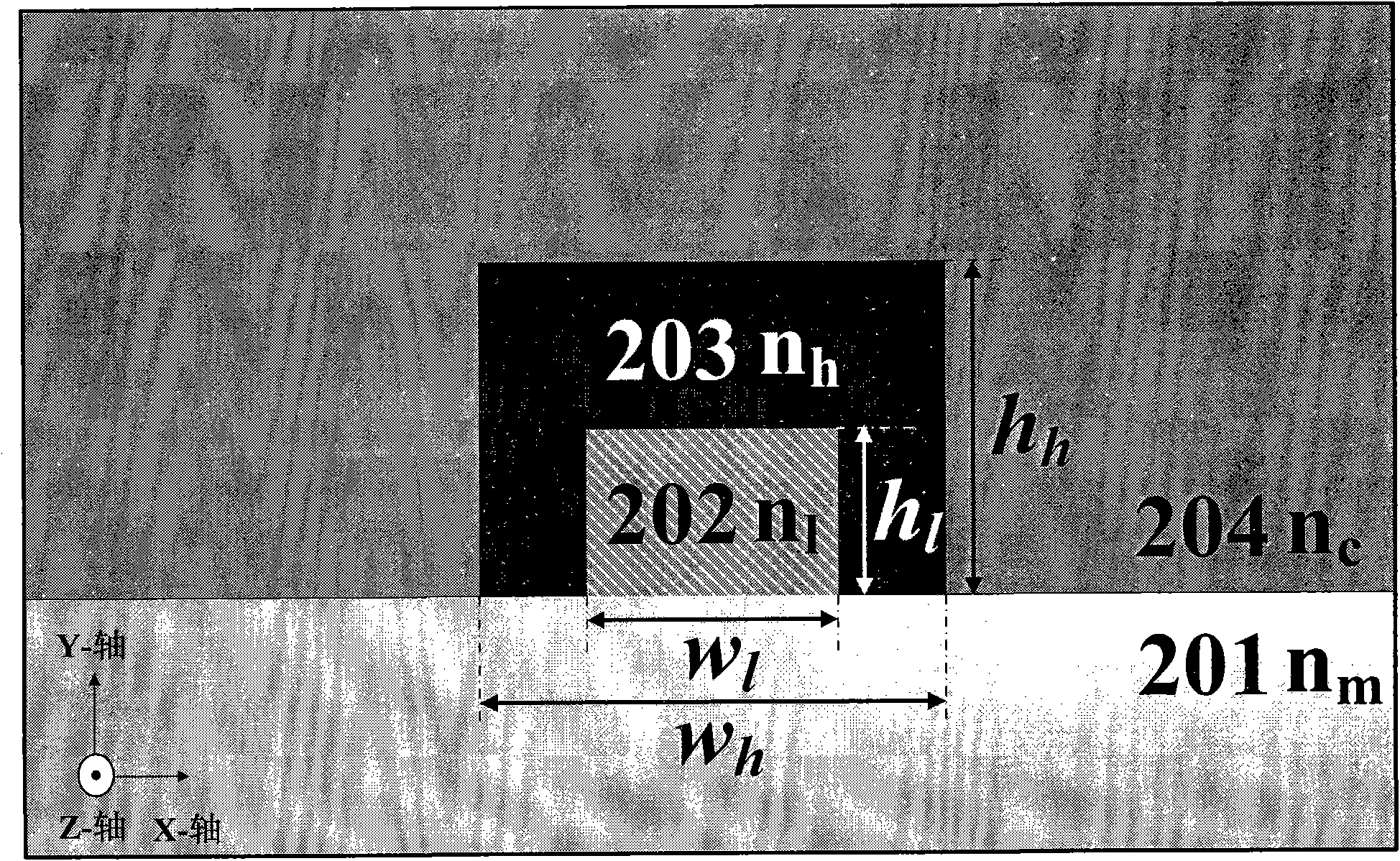

[0036] Example 1: Optical waveguide structure with large difference in refractive index of materials in high and low refractive index medium regions

[0037] figure 2 It is the structural diagram of the dielectric-loaded surface plasmon optical waveguide described in Example 1. 201 is the metal base layer, n m Its refractive index; 202 is the low refractive index medium area, n 1 is its refractive index, W l its width, h l Its height; 203 is the high emissivity medium area, n h is its refractive index, W h its width, h h Its height; 204 is cladding, n c for its refractive index.

[0038] In this example, the wavelength of the transmitted optical signal is selected as 1.55 μm, the material of 201 is silver, and the refractive index at the wavelength of 1.55 μm is 0.1453+i*11.3587; the material of 202 is set as air, and its refractive index is 1 ; The material of 203 is silicon, whose refractive index is 3.5; the material of 204 is silicon dioxide, whose refractive ind...

example 2

[0045] Example 2: Optical waveguide structure with small difference in refractive index of materials in high and low refractive index medium regions

[0046] The structural diagram of the dielectric-loaded surface plasmon optical waveguide described in Example 2 is shown in figure 2 . 201 is the metal base layer, n m Its refractive index; 202 is the low refractive index medium area, n 1 is its refractive index, W l its width, h l Its height; 203 is the high emissivity medium area, n h is its refractive index, W h its width, h h Its height; 204 is cladding, n c for its refractive index.

[0047] In this example, the wavelength of the transmitted optical signal is selected as 1.55 μm, the material of 201 is silver, and the refractive index at the wavelength of 1.55 μm is 0.1453+i*11.3587; the material of 202 is silicon nitride, and its refractive index 2; the material of 203 is silicon, whose refractive index is 3.5; the material of 204 is silicon dioxide, whose refrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com