Self-cleaning washing bottle

A bottle washing and bottle cap technology, which is applied in the field of bottle washing to achieve the effect of prolonging the service life, reducing the risk of pollution and reducing the consumption of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

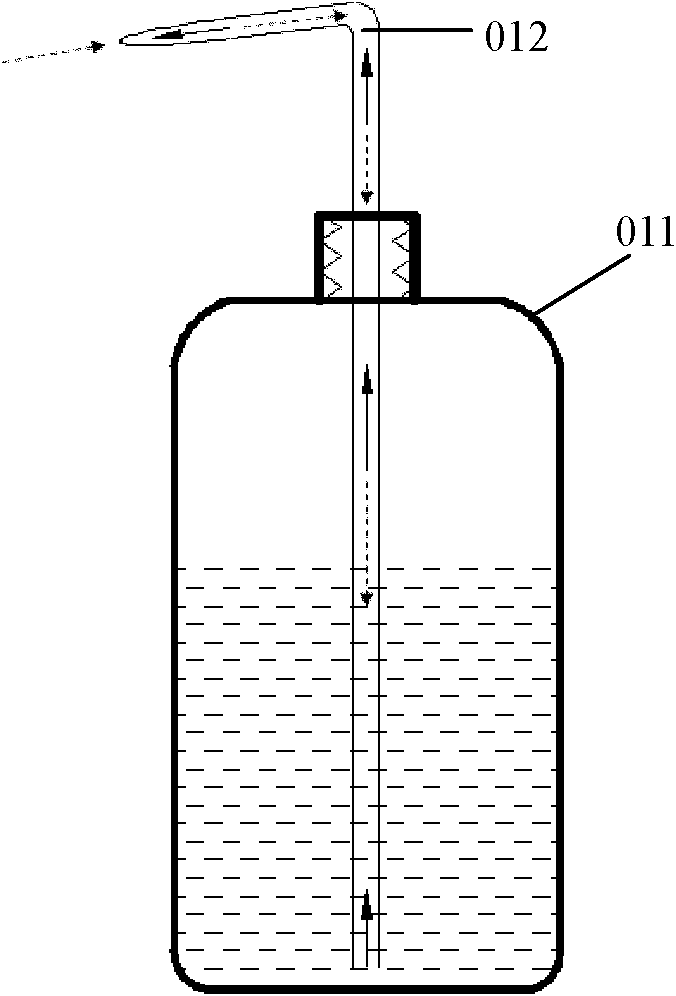

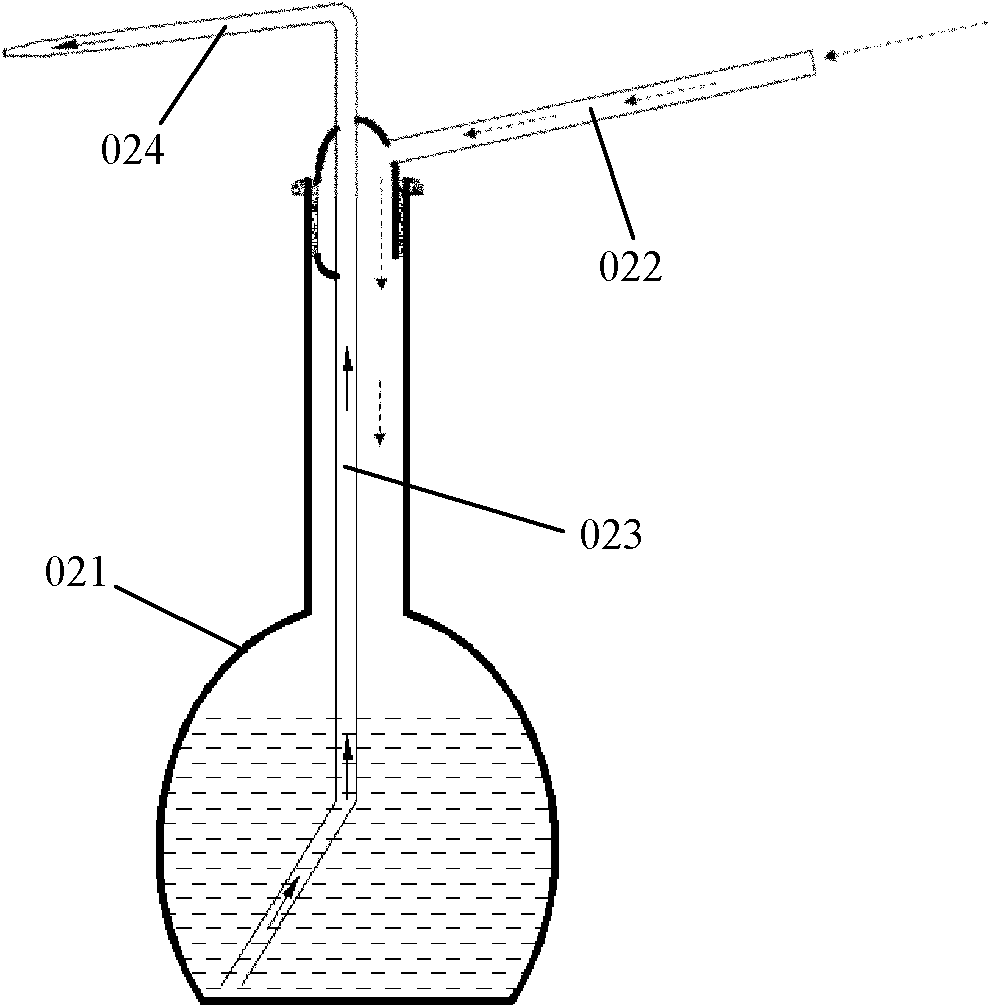

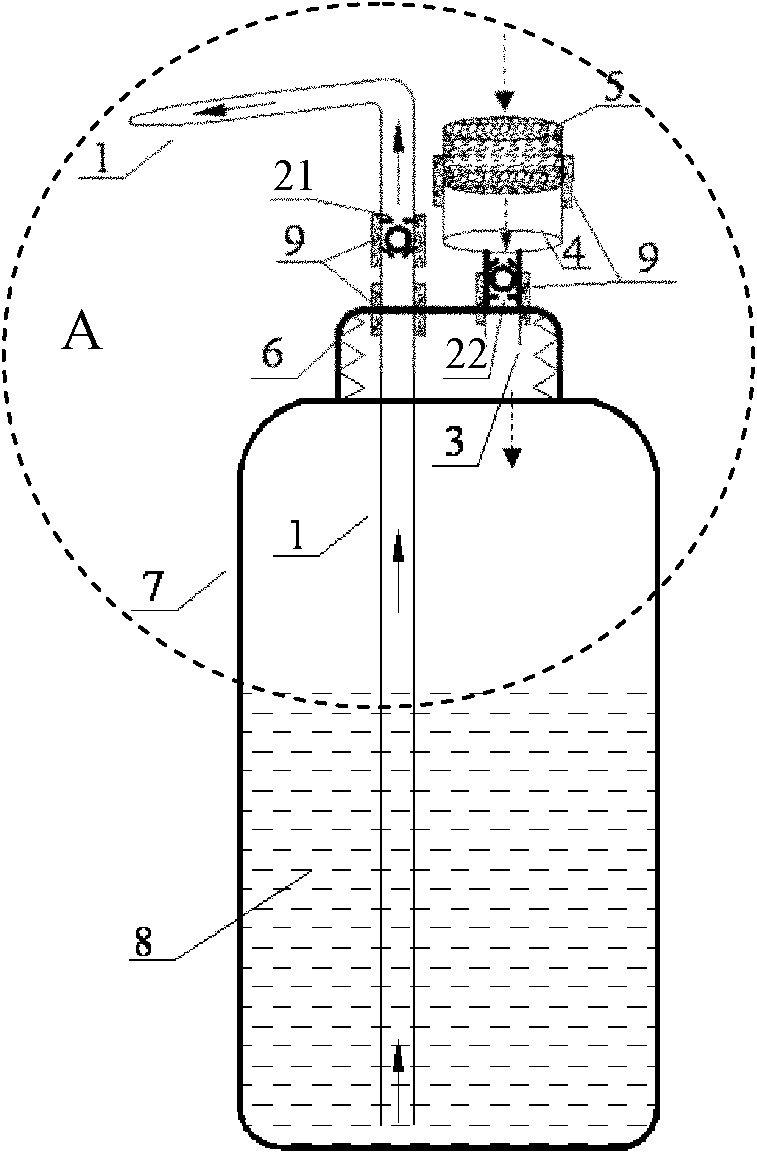

[0032] Embodiment 1 self-cleaning bottle washing with gas filtering function

[0033] 1) if image 3 and Figure 4 As shown, the embodiment of the present invention is provided with plastic bottle (adopting the 500mL polyethylene bottle with good airtightness) 7, bottle cap 6, spray pipe 1, suction pipe 3 and purifying device (adopting needle type filter purifying device) 5 , the bottle cap 6 is matched with the mouth of the plastic bottle 7, the liquid spray pipe 1 is provided with a check valve or a one-way valve 21, the liquid spray pipe 1 passes through the bottle cap 6 and is inserted into the plastic bottle 7, and the suction pipe 3 Insert the top of the plastic bottle 7 through the bottle cap 6, the suction pipe 3 is provided with a check valve or a one-way valve 22, the inlet of the check valve or the one-way valve 22 is connected to the purification device 5, the check valve or the one-way valve The outlet of 22 connects suction pipe 3. The liquid spray pipe 1 has ...

Embodiment 2

[0037] Embodiment 2 Purification device capable of adsorbing impurity gas

[0038] Such as Figure 5 and 6 As shown, the purification device with polypropylene plastic pipe as the main body is composed of an outer pipe 14 with an inner diameter of 5 mm and two inner pipes 10 with an outer diameter of 4 mm and an inner diameter of 3 mm. The inner pipe and the outer pipe are connected, and a jacket is placed between the two Layer the tubing with silicone rubber 9 to ensure a tight seal. When in use, first connect a section of the inner tube to one end of the outer tube, insert a certain amount of glass wool into the interface, fill the outer tube with a gas adsorbent (such as 4A molecular sieve) until it is nearly full, then insert a certain amount of glass wool and connect it. The upper part of the inner tube is a purification device that can absorb impurity gases. When the purification device with the syringe barrel as the main body is implemented, a circular polyethylene s...

Embodiment 3

[0039] Embodiment 3 self-cleaning bottle washing with gas adsorption function

[0040] Such as image 3 and 4 As shown, the purification device in embodiment 1 is changed into the purification device in embodiment 2 (filling 4A type molecular sieve), and the plastic bottle is then replaced with Teflon fluorinated polyethylene propylene (FEP) material with equivalent specifications, and the inner diameter and purification ratio are selected. The equivalent polytetrafluoroethylene tube of device external diameter is as suction pipe 3, and the manufacture method of liquid spray pipe 1 and suction pipe 3 is with embodiment 1. The thus prepared self-cleaning washing bottle can effectively remove acid gases such as carbon dioxide, hydrogen sulfide and sulfur dioxide in the air, and can be used for containing alkaline solutions such as sodium hydroxide solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com