Method for performing quick anaerobic fermentation on chicken manure by supplying carbon source by using straws

A technology for anaerobic fermentation and carbon source supplementation, which is applied in the fields of fermentation, application, and preparation of organic fertilizers. It can solve the problems of insufficient gas production in chicken manure fermentation and easy acidification in the fermentation process. It achieves good results, is easy to popularize, and uses methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

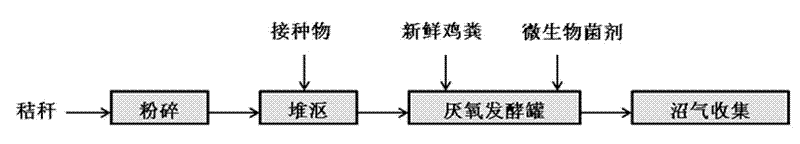

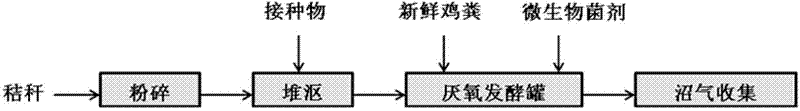

[0041] (1) Choose 160kg of rice straw without toxic substance pollution, and crush it manually or mechanically, with a length of 1-2cm. Wet the crushed stalks with inoculum according to the weight ratio of material to water 1:2, mix the ingredients and seal the stack for 5-6 days.

[0042] (2) Put the mixture of stacked straw and inoculum into the fermenter, add 1300 kg of fresh chicken manure with a moisture content of 80%, add water to prepare a mixture with a moisture content of about 94%, and adjust the pH to 7.2.

[0043] (3) Add 2‰ (volume) of the compound high-efficiency microbial agent, the microbial agent consists of 3 parts by weight of E. coli fermentation broth, 5 parts by weight of Trichoderma fermentation broth, 2 parts by weight of Pseudomonas fluorescens fermentation broth, subtilis 8 parts by weight of bacillus fermented liquid are combined. Stir evenly, seal the lid, anaerobic fermentation at 35±1°C, record gas production with an anti-corrosion gas flow mete...

Embodiment 2

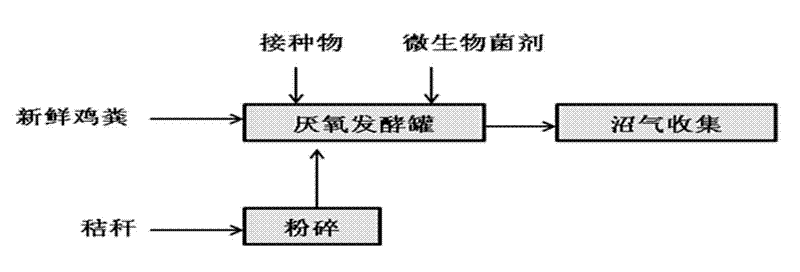

[0047] (1) Take 1200 kg of fresh chicken manure from the chicken farm, add water to make a mixture with a moisture content of about 94%, and add it to the fermenter.

[0048] (2) Add an inoculum accounting for 10% of the volume of the mixture of chicken manure and water, and adjust the pH to 7.3.

[0049] (3) After 3 days of anaerobic fermentation at 35±1°C, add 240 kg of crushed straw with a length of 1-2 cm, add water to adjust the moisture content to 91-92%, and mix well.

[0050] (4) Add 3‰ (volume) of compound high-efficiency microbial agent, which can be composed of 5 parts by weight of Escherichia coli fermentation broth, 8 parts by weight of Trichoderma fermentation broth, 9 parts by weight of Pseudomonas fluorescens fermentation broth, 6 parts by weight of bacillus fermented liquid are combined. Stir well and cover. Anaerobic fermentation at 35±1°C, with regular stirring, anti-corrosion gas flow meter to record gas production, and connect air bag to collect biogas. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com