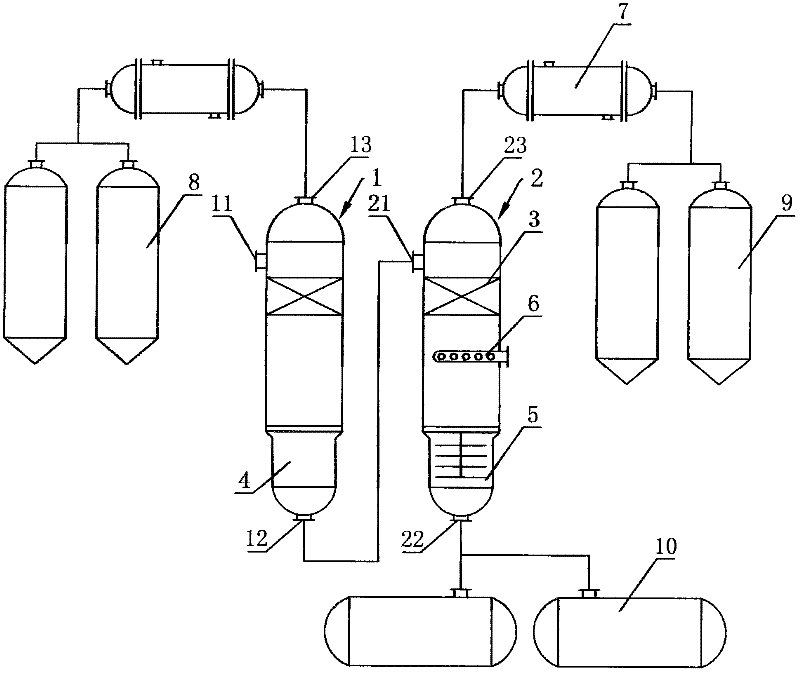

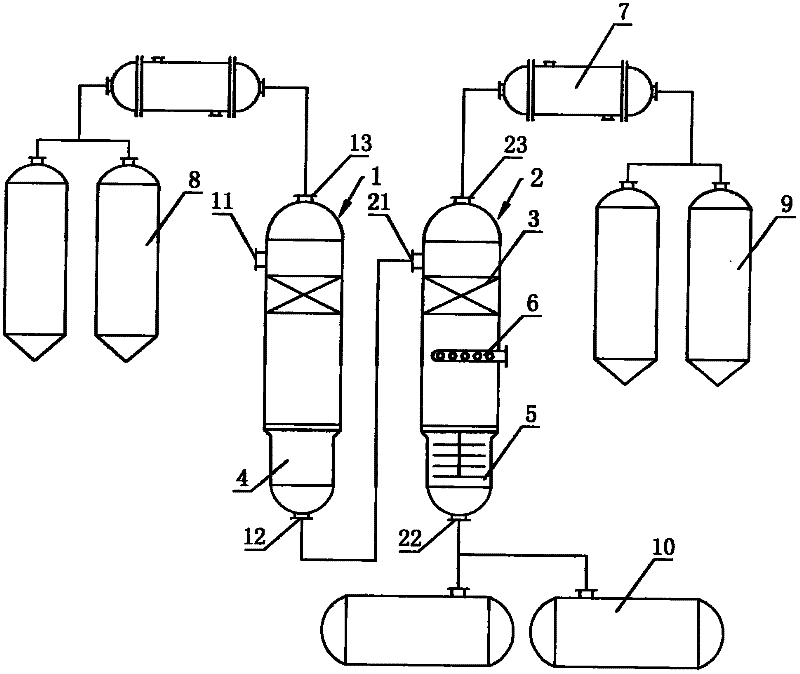

Continuous alcohol-removing device and alcohol-removing method of di-sec-octyl phthalate

A technology of di-sec-octyl phthalate and dealcoholization, which is applied in the continuous dealcoholization device and the field of continuous dealcoholation, can solve the problem of restricting the development of di-sec-octyl phthalate, unable to realize large-scale production and intermittent de-alcoholization. The problem of high energy consumption of alcohol can achieve the effect of stable and uniform product quality, smooth process operation and good dealcoholization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Open the vacuum system of the dealcoholization tower and the stripping tower, open the heating valve to heat the evaporator of the dealcoholization tower, and the materials obtained by the esterification reaction (including di-sec-octyl phthalate and unreacted sec-octyl alcohol) Enter from the material inlet on the upper part of the dealcoholization tower, the feed amount is from small to large, the material temperature in the dealcoholization tower is 170°C, the relative pressure is -0.083MPa, the gas phase temperature at the top of the dealcoholization tower is >90°C, and the relative pressure is -0.084 Pre-dealcoholization is carried out at MPa, and the released secondary octanol is discharged through the outlet of the dealcoholization gas phase, and is condensed by the condenser and then recovered to the dealcoholization receiving tank. reaction. The two dealcoholization receiving tanks and the two stripping receiving tanks connected in parallel are switched for use...

Embodiment 2

[0038]Open the vacuum system of the dealcoholization tower and the stripping tower, open the heating valve to heat the evaporator of the dealcoholization tower, and the materials obtained by the esterification reaction (including di-sec-octyl phthalate and unreacted sec-octyl alcohol) Enter from the material inlet on the upper part of the dealcoholization tower, the feed amount is from small to large, the material temperature in the dealcoholization tower is 172°C, the relative pressure is -0.085MPa, the gas phase temperature at the top of the dealcoholization tower is >90°C, and the relative pressure is -0.086 Pre-dealcoholization is carried out at MPa, and the released secondary octanol is discharged through the outlet of the dealcoholization gas phase, and recovered to the dealcoholization receiving tank after being condensed by the condenser. After the recovered secondary octanol is recovered, it returns to the esterification process to participate in the esterification reac...

Embodiment 3

[0041] Open the vacuum system of the dealcoholization tower and the stripping tower, open the heating valve to heat the evaporator of the dealcoholization tower, and the materials obtained by the esterification reaction (including di-sec-octyl phthalate and unreacted sec-octyl alcohol) Enter from the material inlet on the upper part of the dealcoholization tower, the feed amount is from small to large, the material temperature in the dealcoholization tower is 176°C, the relative pressure is -0.08MPa, the gas phase temperature at the top of the dealcoholization tower is >90°C, and the relative pressure is -0.084 Pre-dealcoholization is carried out at MPa, and the released secondary octanol is discharged through the outlet of the dealcoholization gas phase, and recovered to the dealcoholization receiving tank after being condensed by the condenser. After the recovered secondary octanol is recovered, it returns to the esterification process to participate in the esterification reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com