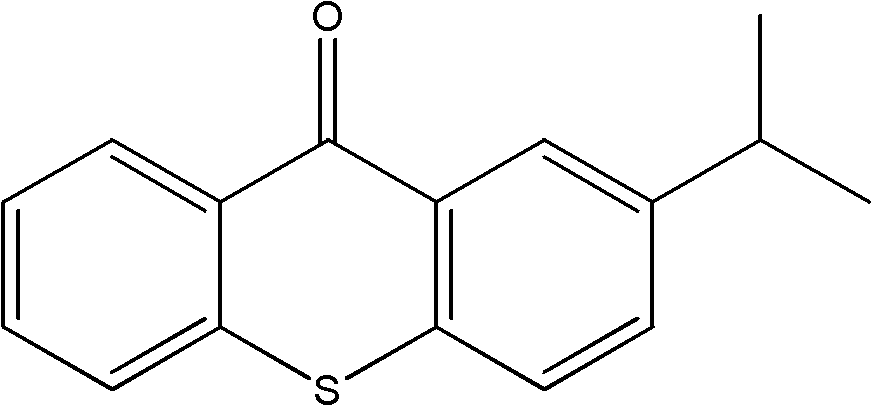

Preparation method of 2-isopropylthioxanthone

A technology of isopropylthioxanthone and propylthiophenol is applied in the field of preparation of 2-isopropylthioxanthone, and can solve the problems of high energy consumption, low efficiency, and unsuitability for large-scale popularization and use. , to achieve the effect of low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

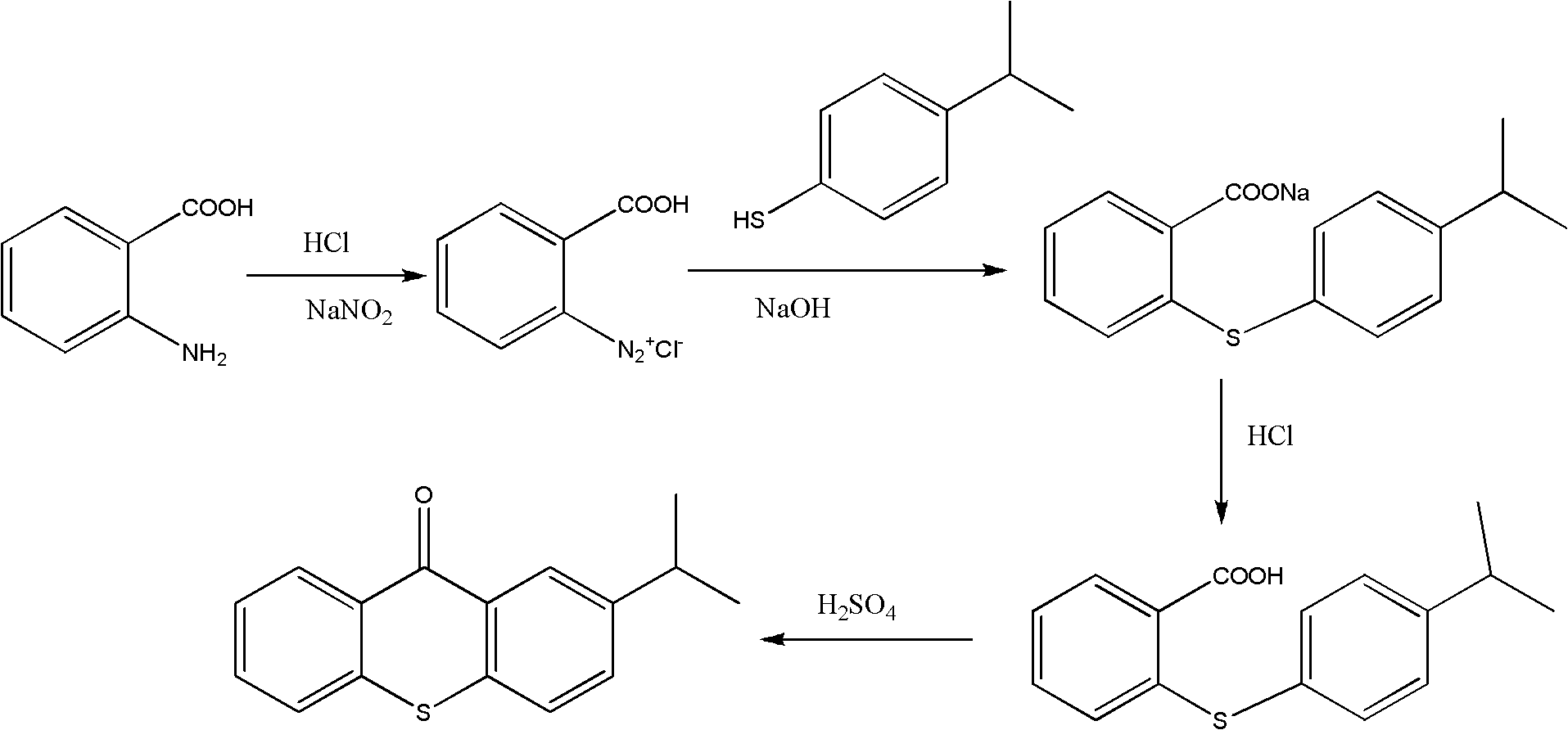

[0023] Embodiment 1, a kind of preparation method of 2-isopropylthioxanthone, carries out following steps successively:

[0024] 1), diazotization reaction: add 30ml water, 13.7g (0.1mol) anthranilic acid, 30.4g (0.25mol, mass concentration 30%) industrial hydrochloric acid under stirring in 250ml three-necked flask, cool to 0 ℃, control 7.4g (0.107mol) of sodium nitrite in 20ml of aqueous solution was added dropwise at 0-5°C. After the dropwise addition was completed, the temperature was controlled at 0-5°C for 30 minutes to obtain the diazonium salt for later use.

[0025] 2), Condensation etherification reaction: Add 80ml of water, 12g (0.3mol) sodium hydroxide, 15.2g (0.1mol) 4-isopropylthiophenol into a 500ml three-necked flask with stirring, stir to dissolve, and control the temperature for 5- Add all the diazonium salt obtained in step 1) dropwise at 15°C, after the dropwise addition is completed, heat up to room temperature at 30-35°C and react for 3h, slowly add 25g (...

Embodiment 2

[0028] The preparation method of embodiment 2,2-isopropylthioxanthone, carries out the following steps successively:

[0029] 1), diazotization reaction: add 30ml water, 13.7g (0.1mol) anthranilic acid, 30.4g (0.25mol, mass concentration 30%) industrial hydrochloric acid under stirring in 250ml three-necked flask, cool to 0 ℃, control 7.4g (0.107mol) of sodium nitrite in 20ml of aqueous solution was added dropwise at 0-5°C. After the dropwise addition was completed, the temperature was controlled at 0-5°C for 30 minutes to obtain the diazonium salt for later use.

[0030] 2) Condensation etherification reaction: Add 80ml of water, 12g (0.3mol) of sodium hydroxide, 15.2g (0.1mol) of 4-isopropylthiophenol into a 500ml three-necked flask with stirring, stir to dissolve, and control the temperature at room temperature for 30 Add dropwise the diazonium salt obtained in step 1) at -35°C, after the dropwise addition, react at room temperature for 3h at 30-35°C, slowly add 25g (mass c...

Embodiment 3-6

[0033] Embodiment 3-6: Change reaction temperature T1 and reaction time t1, 4-isopropylthiophenol addition n1, step 3) in step 2) reaction time t2 in reaction temperature T1, obtain 2-odor propyl thioxanthone The total molar yield of is y, and the specific data results are shown in Table 1.

[0034] Example

[0035] n1,mol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com