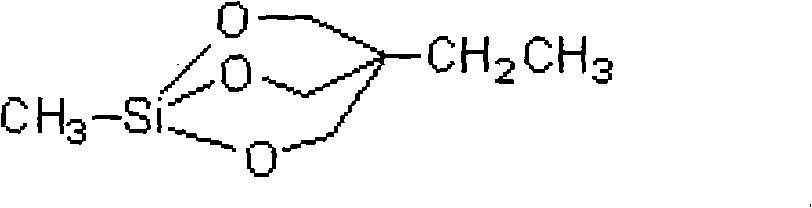

Organic silicon flame-retardant carbon-forming agent and preparation method thereof

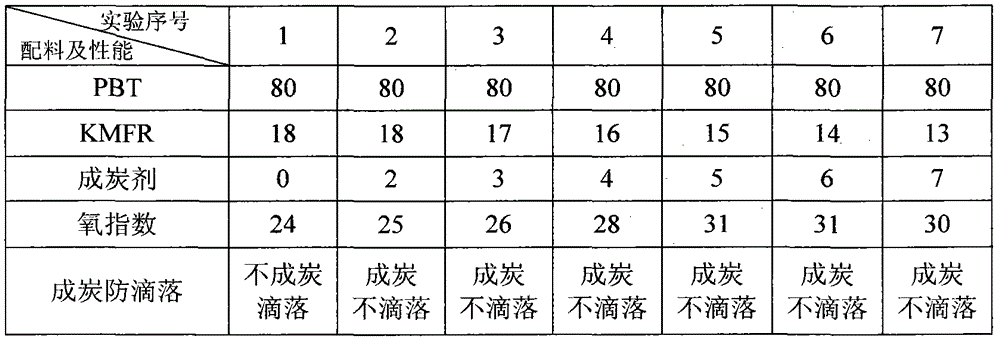

A char-forming agent and organosilicon technology, which is applied in the field of silicon-containing cage-like flame-retardant char-forming agent compounds and their preparation, can solve the problems of no cost-effective char-forming agent or flame-retardant char-forming agent, etc. The effect of good capacitance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

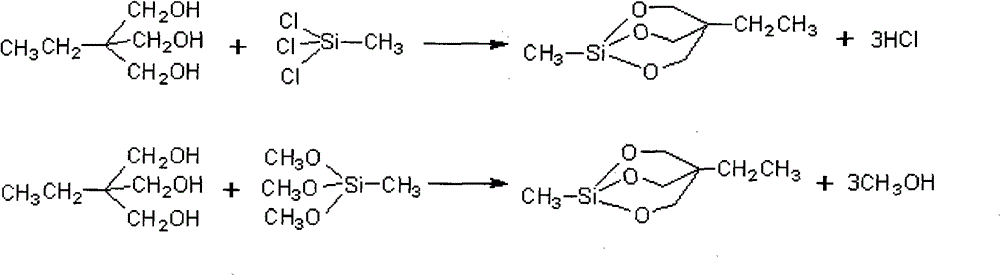

Method used

Image

Examples

Embodiment 1

[0046] Example 1 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device, add 0.1mol (13.42g) trimethylolpropane and 40ml acetonitrile, start stirring, and at 25 0.1 mol (14.95 g) of methyltrichlorosilane was added dropwise within about 30 minutes at ℃, and after the drop was completed, the temperature was raised to 65 ℃ and refluxed for 1 hour. Then the temperature was raised to 80°C for reflux reaction for 18 hours. After the hydrogen chloride was released, it was crystallized by cooling, filtered, and dried to obtain 1-methyl-4-ethyl-1-sila-2,6,7-trioxabicyclo [2,2,2]-Octane White solid. Its yield is 92%, and its decomposition temperature is 370±10°C.

Embodiment 2

[0047] Example 2 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device, add 0.1mol (13.42g) of trimethylolpropane and 40ml of dioxane, and start stirring , at 25°C, add 0.1mol (14.95g) methyltrichlorosilane dropwise within about 30min, and then raise the temperature to 65°C and reflux for 1h after the dropwise completion. Then the temperature was raised to 102°C for reflux reaction for 15 hours. After the hydrogen chloride was released, it was crystallized by cooling, filtered, and dried to obtain 1-methyl-4-ethyl-1-sila-2,6,7-trioxabicyclo [2,2,2]-Octane White solid. Its yield is 93%, and its decomposition temperature is 370±10°C.

Embodiment 3

[0048] Example 3 In a 100ml four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, a reflux condenser and a hydrogen chloride absorption device, add 0.1mol (13.42g) trimethylolpropane and 40ml toluene, start stirring, and at 25 0.1 mol (14.95 g) of methyltrichlorosilane was added dropwise within about 30 minutes at ℃, and after the drop was completed, the temperature was raised to 65 ℃ and refluxed for 1 hour. Then the temperature was raised to 112°C for reflux reaction for 15 hours. After the hydrogen chloride was released, it was crystallized by cooling, filtered, and dried to obtain 1-methyl-4-ethyl-1-sila-2,6,7-trioxabicyclo [2,2,2]-Octane White solid. Its yield is 93%, and its decomposition temperature is 370±10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com