Method for extracting gamma-polydiaminobutyric acid and polylysine from fermentation liquor

A technology of polydiaminobutyric acid and polylysine, which is applied in the field of separation engineering, can solve the problems that plague the industrial production of ε-PL, low product concentration, and low production efficiency, and achieve low cost, high purity, and product yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

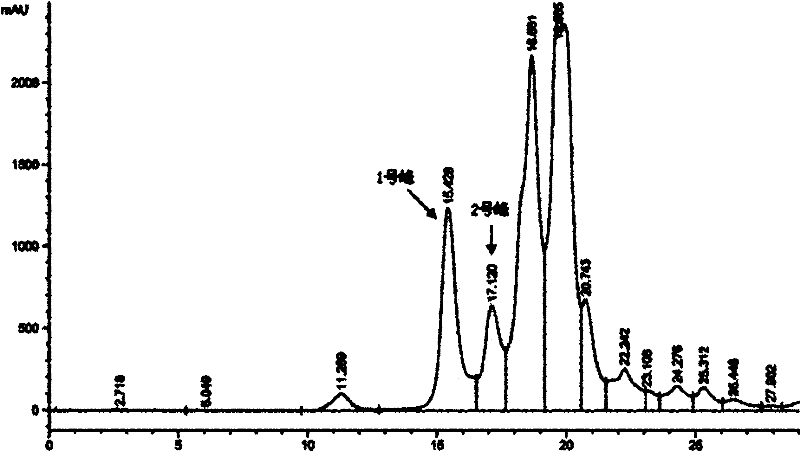

Image

Examples

Embodiment 1

[0041] Example 1: Free fermentation of S.albulus PD-1 in a 5L tank to produce polylysine and polydiaminobutyric acid

[0042] Incline medium: glucose 10g / L, beef extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 0.5g / L, agar 20g / L, pH 7.0.

[0043] Seed medium: glucose 10g / L, beef extract 5g / L, yeast extract 5g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O0.5g / L, utilize 6mol / LNaOH solution to adjust pH 7.0

[0044] Fermentation medium: glucose 50g / L, yeast extract 5g / L, (NH 4 ) 2 SO 4 5g / L, Na 2 HPO 4 12H 2 O 1.58g / L, K 2 HPO 4 ·7H 2 O 0.82g / L, MgSO 4 ·7H 2 O 0.1g / L, use 6mol / L NaOH solution to adjust the pH to 7.0.

[0045] Cultivate Streptomyces albus S. albulus PD-1 (CCTCC NO: M2011043) in the seed medium, 28°C, 200r / min shaker conditions for 24h, and 300mL of seed liquid was mixed with 10% (v / v) seed The amount of inoculation was carried out in a fermenter pre-installed with 2.7L sterilized fermentation medium for free culture. The culture conditions were: 28°C, 400...

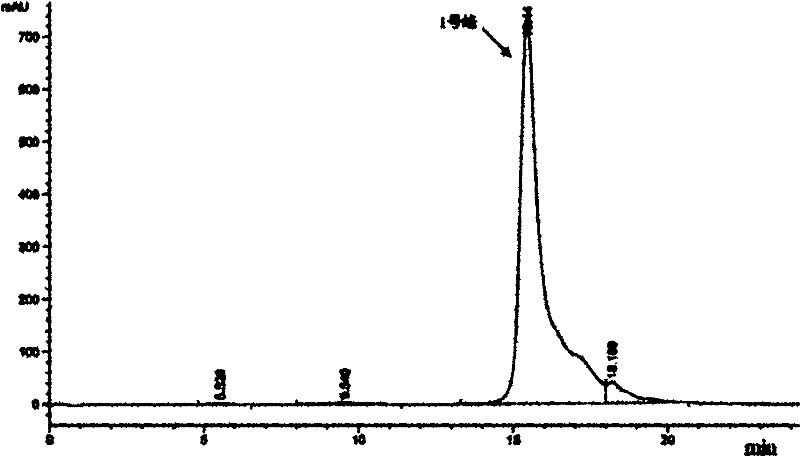

Embodiment 2

[0048] In the acidification tank, use 3mol / L hydrochloric acid to adjust the pH value of the fermentation broth to 2.0, then heat it to 60°C, keep it warm for 20 minutes, cool the acidification solution to room temperature, filter it through a plate and frame, and obtain a clear filtrate after repeated filtration. Use 6mol / L sodium hydroxide solution to adjust the pH value of the filtrate to 9.0 to obtain a pretreatment solution.

[0049] Pump the pretreatment liquid into the adsorption column of weakly acidic cation exchange resin (110) with an aspect ratio of 20:1 for adsorption. During the adsorption process, the flow rate is controlled at 4mL / min (about 2BV / h) until the resin adsorption reaches saturation. Wash the saturated resin with deionized water, control the flow rate to 6mL / min (about 3BV / h), and wash the volume to 3 column volumes. Analyze with pre-prepared 3mol / L hydrochloric acid, control the flow rate at 1mL / min (about 0.5BV / h), and collect polydiaminobutyric ac...

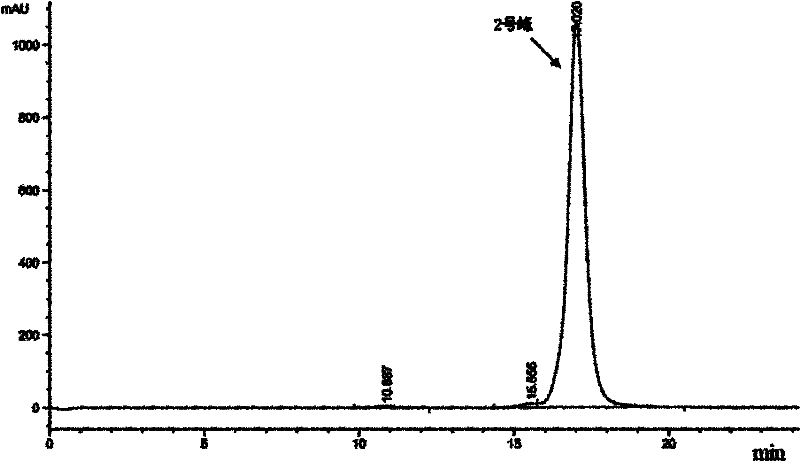

Embodiment 3

[0053] In the acidification tank, use 2mol / L hydrochloric acid to adjust the pH value of the fermentation broth to 5.0, then heat the acidification solution to 100°C, keep it warm for 10 minutes, cool the acidification solution to room temperature, filter it through a plate frame, and obtain a clear filtrate after repeated filtration. Add 6mol / L sodium hydroxide to the clear filtrate, adjust the pH of the clear filtrate to 7.2 to obtain a pretreatment solution.

[0054] Pump the pretreatment solution into the macroporous strong acid ion exchange resin (D001) adsorption column (height-to-diameter ratio: 10:1) for adsorption. During the adsorption process, the flow rate should be controlled at 4mL / min (about 4BV / h) until the resin adsorbs reach saturation. Wash the saturated resin with 5 times the column volume of deionized water at a flow rate of 5 mL / min (about 5 BV / h). Use pre-prepared 1mol / L acetic acid aqueous solution for analysis, control the analysis rate of 1mL / min (ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com