Method for extracting epsilon-polylysine

A polylysine and concentration technology, applied in animal feed, animal feed, animal husbandry, etc., can solve the problems of low yield, cumbersome extraction process, and low content, and achieve low cost, easy equipment and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

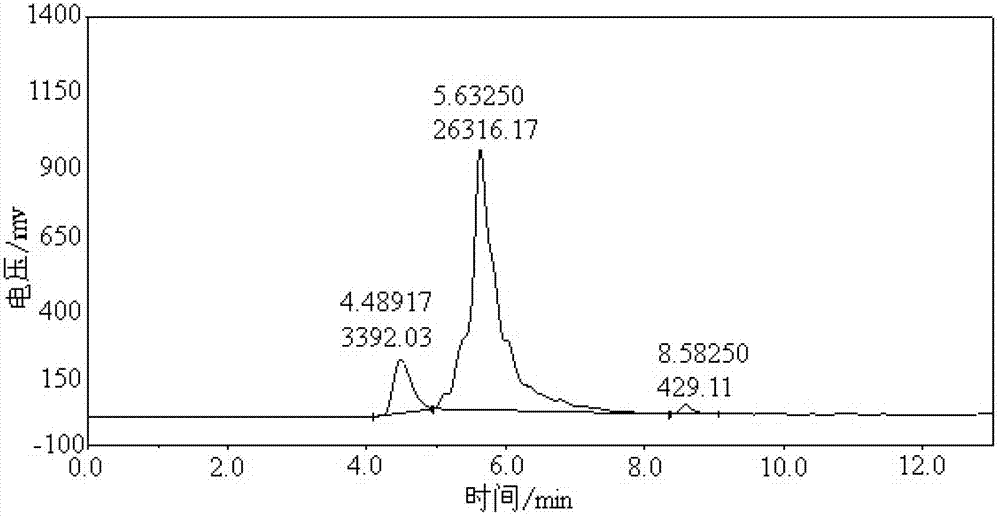

[0032] The fermented liquid just out of the tank has a pH of 3.0-5.0. First heat the fermented liquid to 80°C, keep it warm for 15 minutes, then cool it to 30°C, add diatomaceous earth for adsorption, first use a decanter centrifuge to centrifuge for the first time, and then use The tube centrifuge is used for second centrifugation, and after the bacterial cells are removed by centrifugation, a clear filtrate is obtained. Add a sodium hydroxide solution with a concentration of 5 mol / L to adjust the pH of the filtrate to 8.5 to obtain an alkalized solution. After cooling, put the alkalized hydraulic pressure into the weakly acidic cation exchange resin adsorption column for adsorption. In this embodiment, 152 resin is preferred. The height to diameter ratio of the adsorption column is 5:1. Sodium, to ensure that the pH value of the adsorption process remains at 8.5 until the resin adsorption reaches saturation. Wash with purified water and 0.2mol / L acetic acid solution twice r...

Embodiment 2

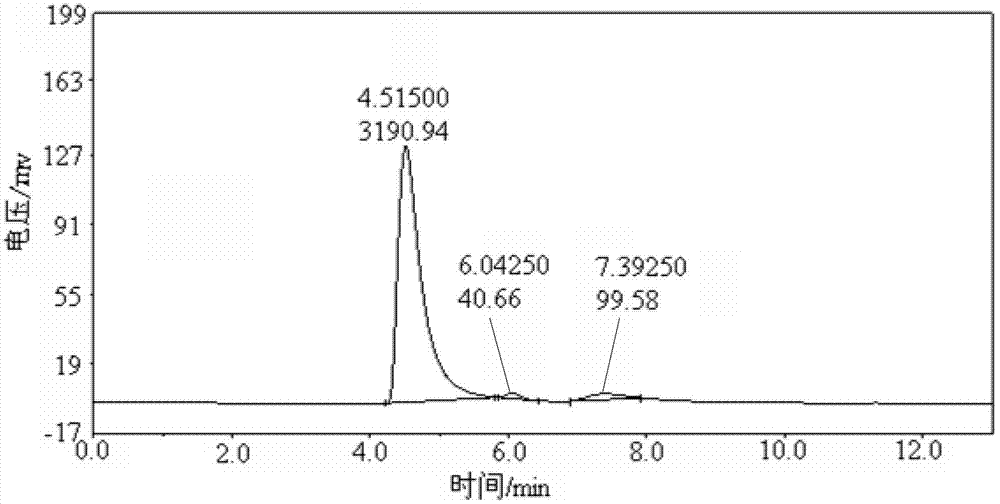

[0035] The fermented liquid just out of the tank has a pH of 3.0-5.0. First heat the fermented liquid to 60°C, keep it warm for 30 minutes, cool to 10°C, add diatomaceous earth for adsorption, first use a decanter centrifuge to centrifuge for the first time, and then use a tube Type centrifuge carries out the second centrifugation, and after centrifugation removes bacterium, obtains clear filtrate. Add a sodium hydroxide solution with a concentration of 5 mol / L to adjust the pH of the filtrate to 10.0 to obtain an alkalized solution. After cooling, put the alkalized hydraulic pressure into the weakly acidic cation exchange resin adsorption column for adsorption. In this embodiment, HD-2 resin is preferred. The height to diameter ratio of the adsorption column is 10:1. The adsorption process controls the flow rate to 4BV / h while continuously adding hydrogen Sodium oxide, to ensure that the pH value of the adsorption process remains at 10.0 until the resin adsorption reaches sat...

Embodiment 3

[0038] The fermented liquid just out of the tank has a pH of 3.0-5.0. First heat the fermented liquid to 100°C, keep it warm for 5 minutes, cool to 60°C, add diatomaceous earth for adsorption, first use a decanter centrifuge to centrifuge for the first time, and then use a tube Type centrifuge carries out the second centrifugation, and after centrifugation removes bacterium, obtains clear filtrate. Add a sodium hydroxide solution with a concentration of 5 mol / L to adjust the pH of the filtrate to 6.0 to obtain an alkalized solution. After cooling, put the alkalized hydraulic pressure into the weakly acidic cation exchange resin adsorption column for adsorption. In this embodiment, HD-2 resin is preferred. The height and diameter ratio of the adsorption column is 2:1. Sodium hydroxide is used to ensure that the pH value of the adsorption process remains at 6.0 until the resin adsorption reaches saturation. Wash with purified water and 0.5mol / L acetic acid solution twice respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com