Carbon-coated magneto-rheological fluid

A magnetorheological fluid and carbon coating technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor anti-settling resistance, high zero-field viscosity, and heavy weight of magnetorheological fluids, and achieves a reduction in quality and zero Field viscosity, the effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

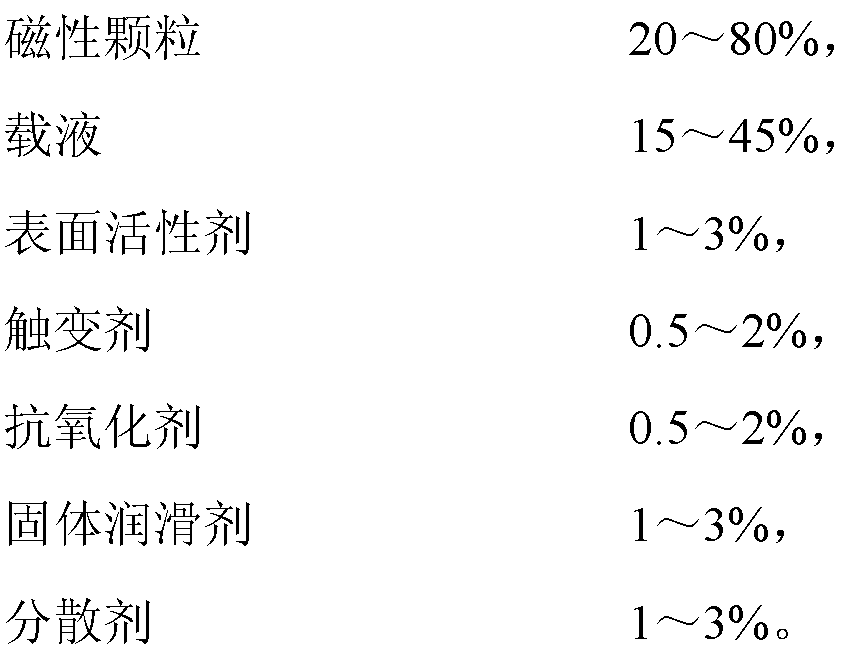

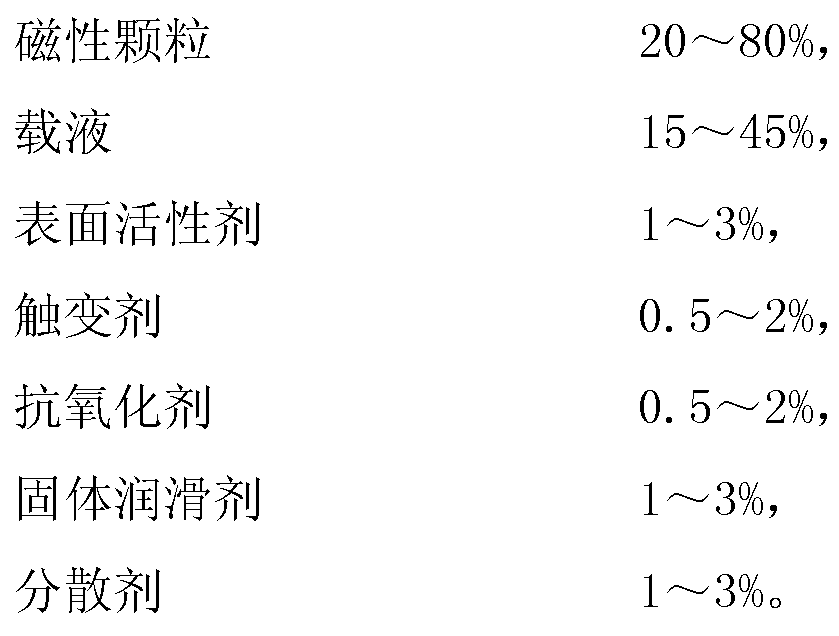

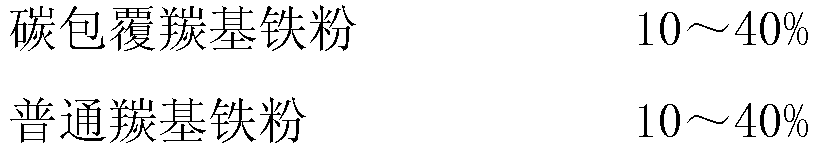

[0018] Example 1: Take 30 grams of carbon-coated carbonyl iron powder after surface treatment, 48 grams of ordinary grade carbonyl iron powder, and 48 grams of methyl silicone oil. 3.6 grams of solid lubricant graphite, 0.6 grams of thixotropic organic bentonite, 2.4 grams of sodium lauryl sulfate, 1.2 grams of antioxidant phenyl-α-naphthylamine, and 1.2 grams of liquid paraffin.

example 2

[0019] Example 2: Take 42 grams of carbon-coated carbonyl iron powder and 42 grams of ordinary carbonyl iron powder after surface treatment, and 54 grams of vegetable oil. 1.2 grams of solid lubricant graphite, 1.2 grams of thixotropic organic bentonite, 3.6 grams of sodium lauryl sulfate, 0.6 grams of antioxidant phenyl-α-naphthylamine, and 2.4 grams of liquid paraffin.

example 3

[0020] Example 3: Take 48 grams of carbon-coated carbonyl iron powder and 48 grams of ordinary carbonyl iron powder after surface treatment, and 54 grams of vegetable oil. 2.4 grams of solid lubricant graphite, 2.4 grams of thixotropic organic bentonite, 3.2 grams of sodium lauryl sulfate, 0.8 grams of antioxidant phenyl-α-naphthylamine, and 3.6 grams of liquid paraffin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com