Environment-friendly textile printing pearlescent adhesive cement and preparation method and application thereof

An environmentally friendly printing technology, applied in the field of printing, to improve the microcirculation of the human body, broaden the use, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Manual platen pearlescent glue printing process:

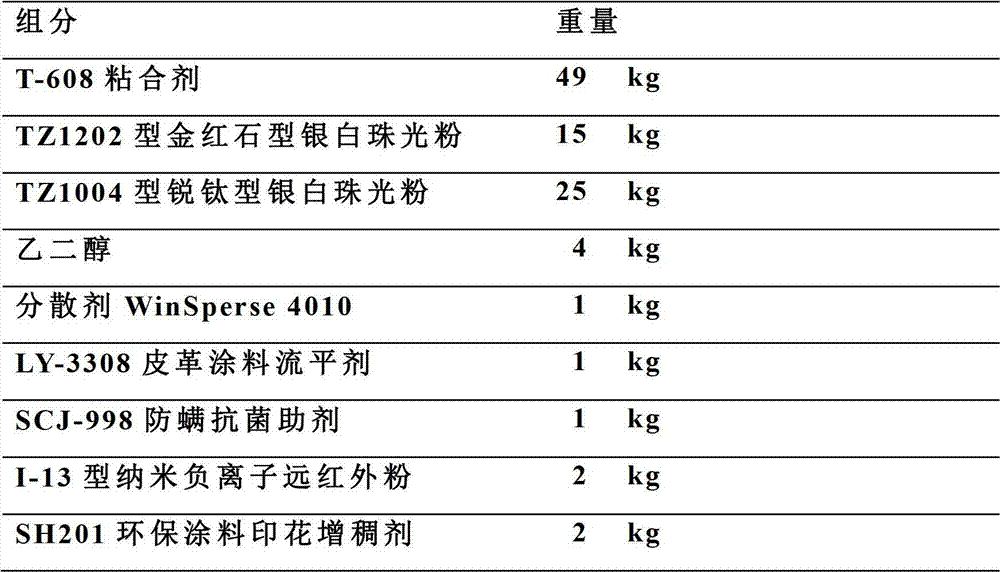

[0030]The formula of the environment-friendly type textile printing pearlescent glue that the present embodiment adopts:

[0031]

[0032] After adjusting the pH value of the environment-friendly adhesive, pour anatase silver-white pearl powder, rutile silver-white pearl powder, ethylene glycol, dispersant, leveling agent, anti-mold and antibacterial additives, and nano-anion far-infrared powder into the adjusted In the adhesive with a good pH value, first stir at a low speed of 1400 rpm for 5 minutes, with a gap of 5 minutes, then add the thickener while stirring at a high speed of 2850 rpm, stop adding the thickener when the required consistency is reached, and continue to high speed After stirring at 2850 rpm for 8 / min, it was confirmed that the surface of the slurry was bright and delicate, and the finished glue of this embodiment was obtained.

[0033] The printed fabric based on 14656 plain crepe ...

Embodiment 2

[0034] Embodiment 2 Synchronous printing process of hand-made plate pearlescent glue and acid dyes

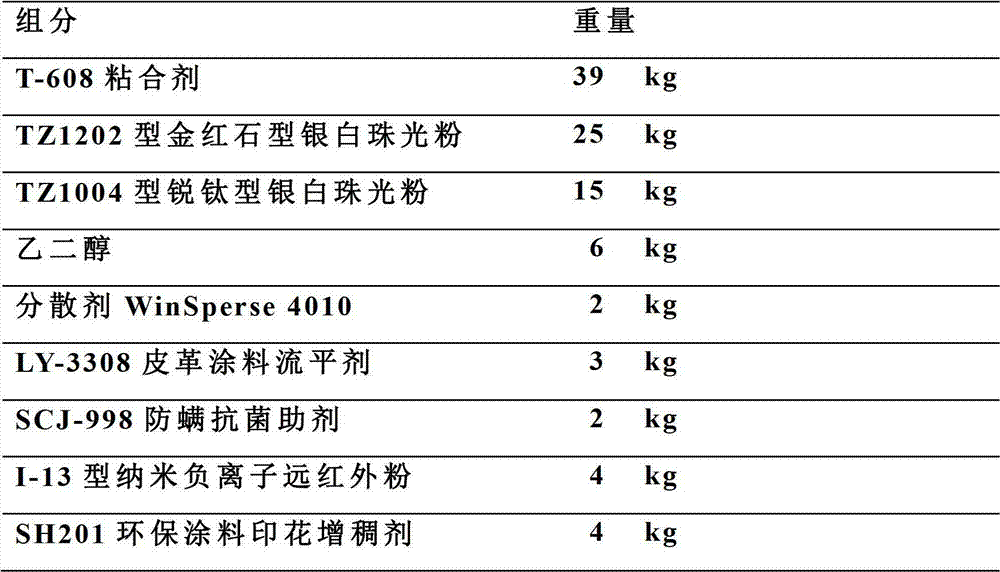

[0035] The formula of the environment-friendly type textile printing pearlescent glue that the present embodiment adopts:

[0036]

[0037] After adjusting the pH value of the environment-friendly adhesive, pour anatase silver-white pearl powder, rutile silver-white pearl powder, ethylene glycol, dispersant, leveling agent, anti-mold and antibacterial additives, and nano-anion far-infrared powder into the adjusted In the adhesive with a good pH value, first stir at a low speed of 1400 rpm for 5 minutes, with a gap of 5 minutes, then add the thickener while stirring at a high speed of 2850 rpm, stop adding the thickener when the required consistency is reached, and continue to high speed After stirring at 2850 rpm for 8 / min, it was confirmed that the surface of the slurry was bright and delicate, and the finished glue of this embodiment was obtained.

[0038] Printing fabric...

Embodiment 3

[0039] Example 3 Machine printing flat screen pearl glue and disperse dye synchronous printing process circuit

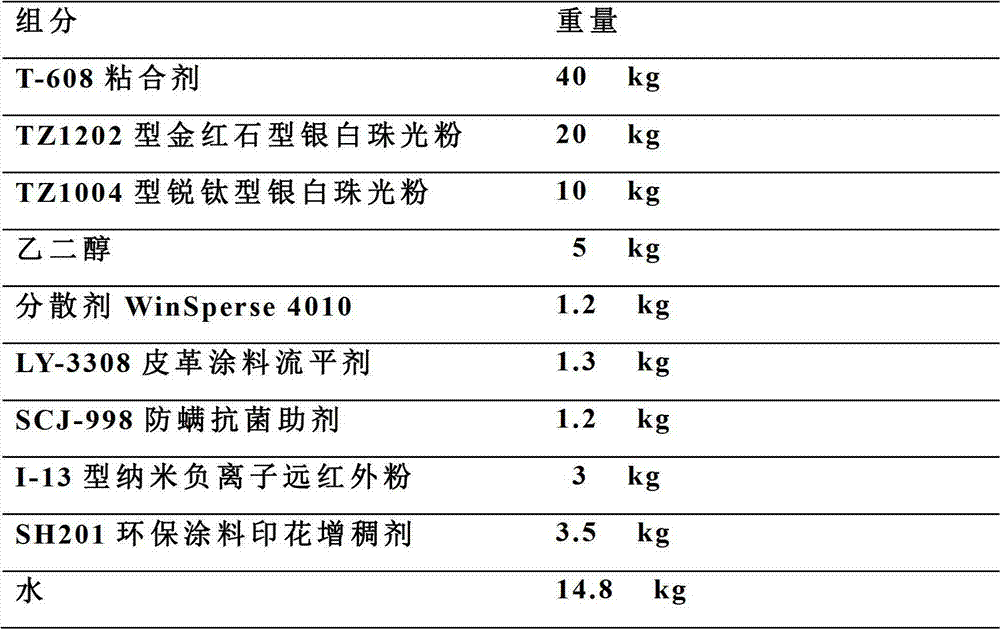

[0040] The formula of the environment-friendly type textile printing pearlescent glue that the present embodiment adopts:

[0041]

[0042] After adjusting the pH value of the environment-friendly adhesive, pour anatase silver-white pearl powder, rutile silver-white pearl powder, ethylene glycol, dispersant, leveling agent, anti-mold and antibacterial additives, and nano-anion far-infrared powder into the adjusted In the adhesive with a good pH value, first stir at a low speed of 1400 rpm for 5 minutes, with a gap of 5 minutes, then add the thickener while stirring at a high speed of 2850 rpm, stop adding the thickener when the required consistency is reached, and continue to high speed After stirring at 2850 rpm for 8 / min, it was confirmed that the surface of the slurry was bright and delicate, and the finished glue of this embodiment was obtained.

[0043] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com