Freeze-dried rice gruel and production technology thereof

A production process and freeze-drying technology, applied in application, food preparation, food science, etc., to achieve the effect of uniform color, convenient eating and soft taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The production process of the freeze-dried rice porridge comprises the steps of washing, soaking, steaming, stewing, slowly freezing and freeze-drying the cereal grains.

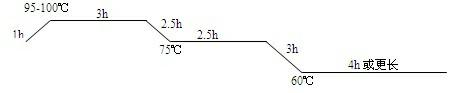

[0027] Soak the rice in water for 20-30 minutes, the water consumption for soaking is 2-4 times of the rice mass, and the water temperature is 50-60°C. The cooking is to add additives to the soaked cereal coarse grains to form a mixed material, then add boiling water, mix evenly, and cook. The composition and mass parts of the additives are: 10 parts of sodium bicarbonate, 10 parts of carbonic acid 15 parts of calcium, 3 parts of citric acid, 5 parts of vitamin C, 20 parts of brown rice flour. The added amount of boiling water is 7-8 times of the mass of coarse grains, and the amount of the additive accounts for 5-6‰ of the mass of coarse grains. The stewing is to stew the steamed mixed material for 10 minutes. The slow freezing is to place the stewed mixed material flatly in the mold, and slow free...

Embodiment 2

[0030] The coarse grains used in a freeze-dried rice porridge are corn and oats, soaked in water for 30 minutes, the water temperature is 50°C, the composition and mass parts of the additives are: 20 parts of sodium bicarbonate, 8 parts of calcium carbonate, 8 parts of citric acid 2 parts of vitamin C, 40 parts of brown rice flour, the added amount accounts for 6‰ of the quality of coarse grains.

[0031] The parts not mentioned above are the same as in Embodiment 1.

Embodiment 3

[0033] The coarse grains used in a freeze-dried rice porridge are barley and sorghum, soaked in water for 20 minutes, the water temperature is 60°C, the composition and mass parts of the additives are: 12 parts of sodium bicarbonate, 10 parts of calcium carbonate, 4 parts of citric acid parts, 4 parts of vitamin C, 30 parts of brown rice flour, the added amount accounted for 5‰ of the quality of coarse grains.

[0034] The parts not mentioned above are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com