Hot roller warm-rolling device and method for metal plates and strips

A technology of metal strips and heating devices, applied in metal rolling, metal rolling, metal processing equipment, etc., to achieve the effects of low cost, good application prospects, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The size of the upper and lower rolls of the two-roll strip mill used is Φ180mm×300mm, the material of the rolls is 9Cr2Mo forged steel, the rolling force of the rolling mill is 50 tons, and the rolling speed is controllable;

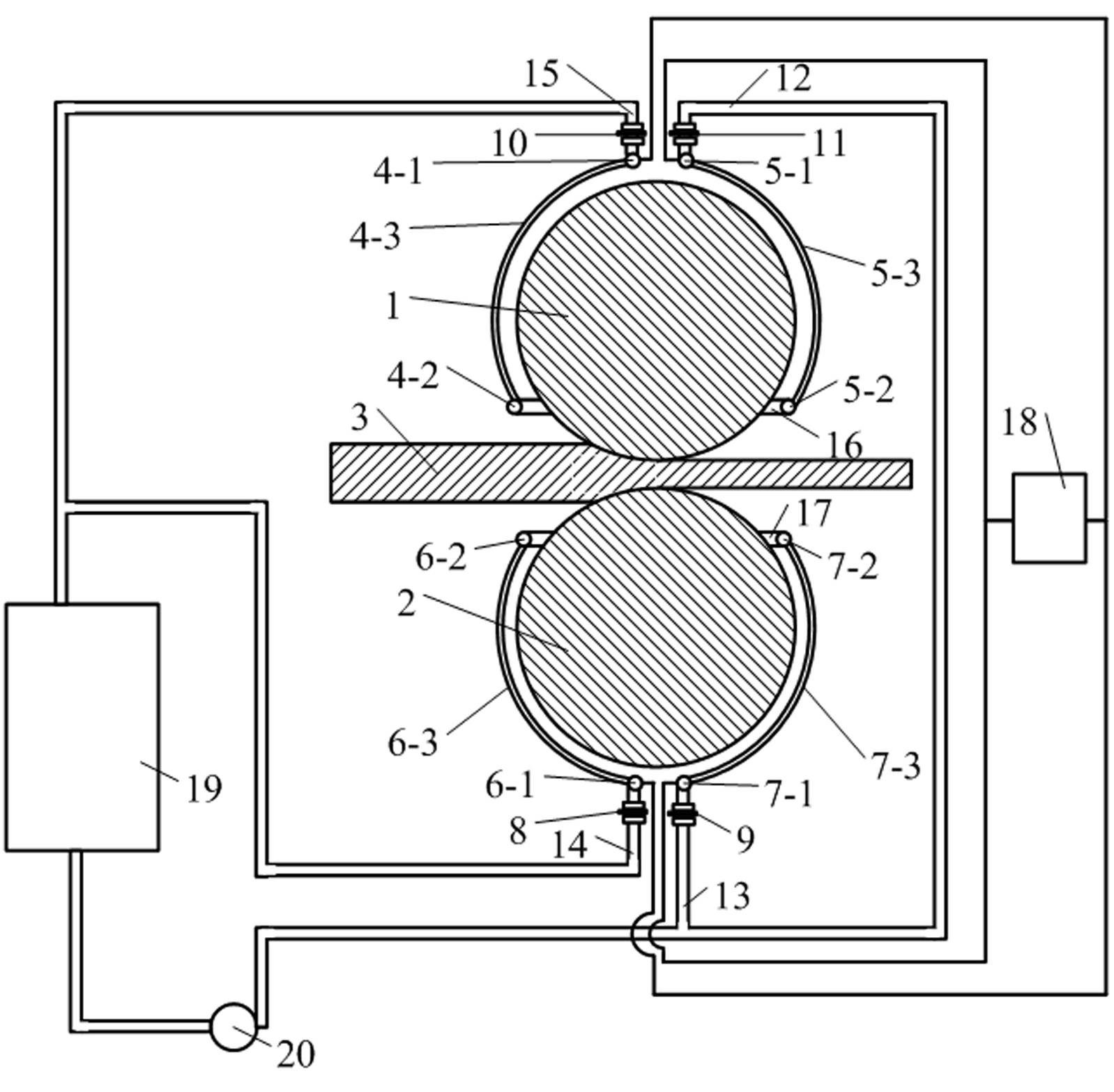

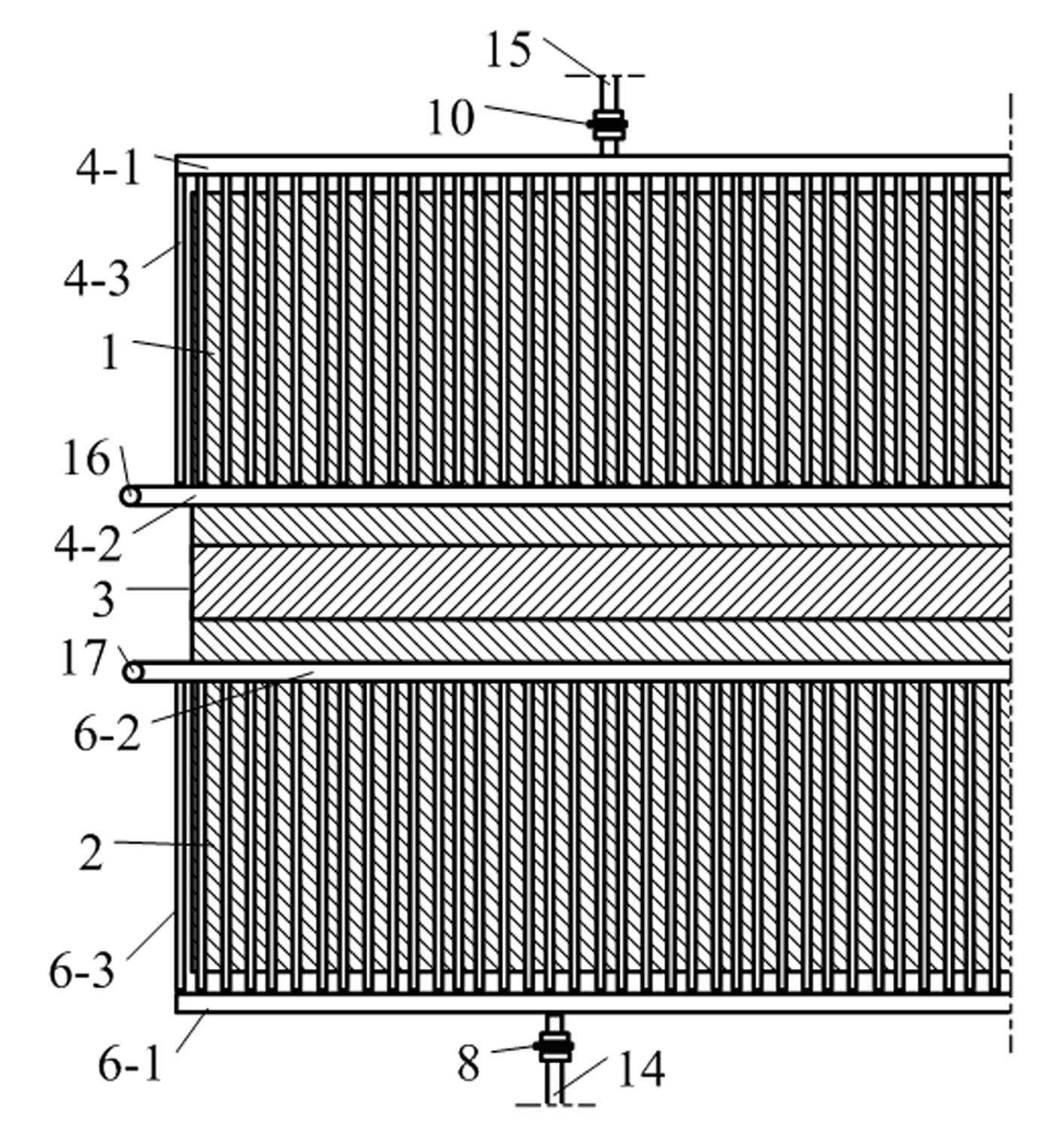

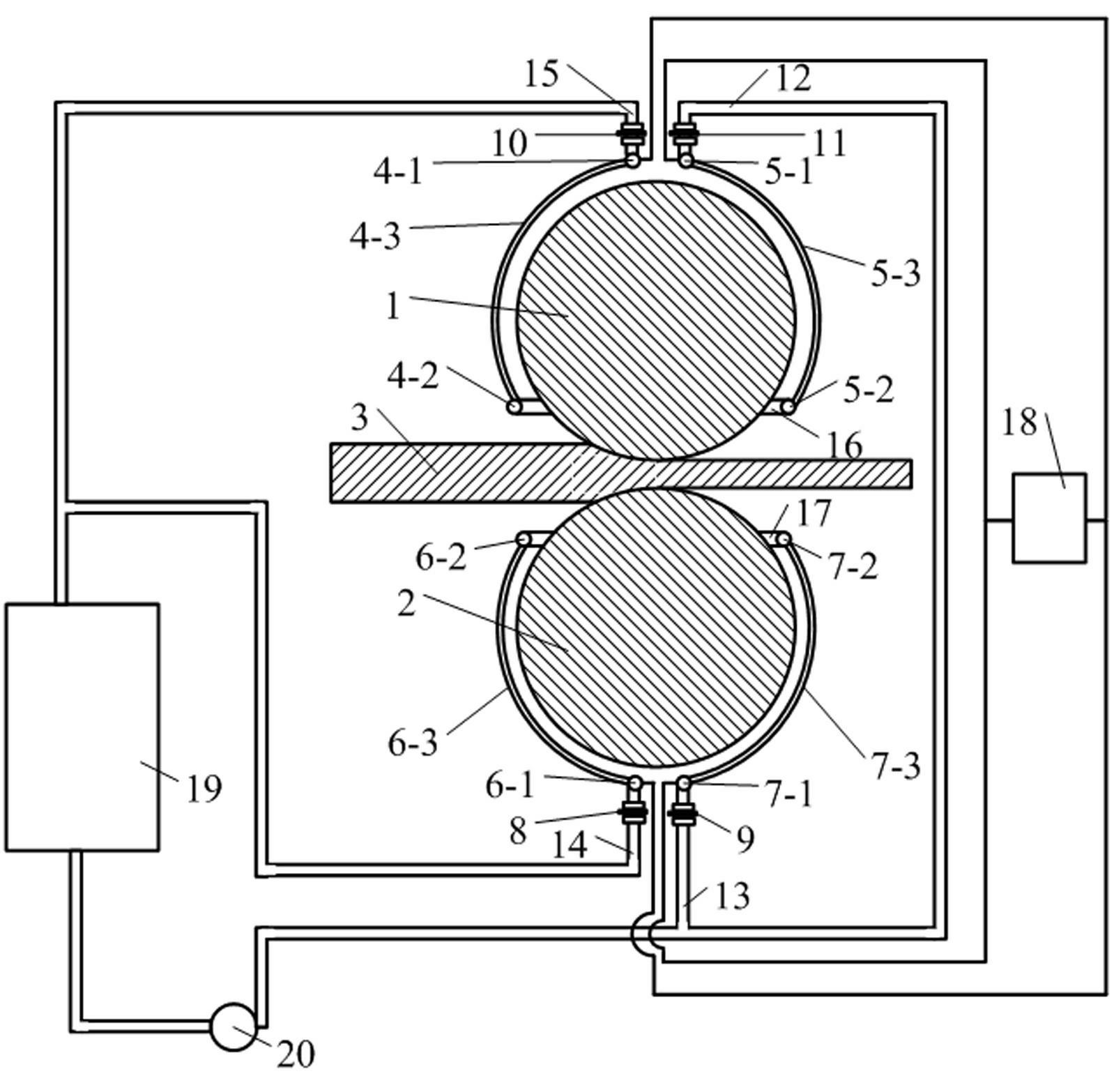

[0025] The structure of the hot rolling and warm rolling device for metal plates and strips is as follows: figure 1 As shown, the side-view local structure is as figure 2 As shown, the two-roll rolling mill includes an upper roll 1 and a lower roll 2; a metal pipe frame is respectively provided at a close distance between the two rolls, and the metal pipe frame is composed of two symmetrically arranged metal pipe groups and a connecting pipe; each metal The pipe group is composed of upper collecting pipe, lower collecting pipe and multiple arc-shaped metal pipes;

[0026] In the metal pipe rack on the outer side above the upper roller 1, the first arc-shaped metal pipe 4-3 of the upper roller, the first upper collecting pipe 4-1 of the upper ro...

Embodiment 2

[0044] The roll material of the two-roll strip mill is chilled cast iron;

[0045] The structure of the hot roll warm rolling device of metal plate and strip is the same as embodiment 1, and the difference is:

[0046] (1) The radian of each arc-shaped metal tube is 125°, and the distance between adjacent arc-shaped metal tubes in each metal tube group is 4mm; the distance between the metal tube group and the roll surface is 10mm; The inner diameter of the tube is 12mm and the wall thickness is 1.5mm;

[0047] (2) The width of each metal tube group is 90% of the axial length of the roll;

[0048] Adopt above-mentioned device to carry out the hot roll warm rolling of metal sheet and strip; The material of the metal sheet and strip raw material that adopts is TC4 titanium alloy, and the thickness of material is 2.5mm, and width is 130mm, and length is 300mm;

[0049] When rolling TC4 titanium alloy, the surface temperature of the roll is 865±5°C, the thickness of the titanium ...

Embodiment 3

[0051] The two-roll strip mill that adopts is the same as embodiment 1,

[0052] The structure of the hot rolling and warm rolling device of metal plate and strip is the same as that of embodiment 1, the difference is that:

[0053] (1) The arc of each arc-shaped metal tube is 130゜, and the distance between adjacent arc-shaped metal tubes in each metal tube group is 5mm; the distance between each arc-shaped metal tube and the surface of the roll is 20mm; the arc The inner diameter of the shaped metal tube is 12mm, and the wall thickness is 1.5mm;

[0054] (2) The width of each metal tube group is equal to the axial length of the roll;

[0055] Adopt above-mentioned device to carry out the hot roll warm rolling of metal sheet and strip; The material of the metal sheet and strip raw material that adopts is Mo-1 molybdenum; The thickness of material is 2.5mm, and width is 135mm, and length is 300mm;

[0056] When rolling molybdenum, the roll surface temperature is 835±5°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com