Process for producing natural gas by coal coking and pyrolysis coal gas thereof

A technology for pyrolysis of coal gas and natural gas, which is applied in the chemical industry, heating of coke ovens, sustainable manufacturing/processing, etc. Enhance product competitiveness, improve practical value, and increase the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

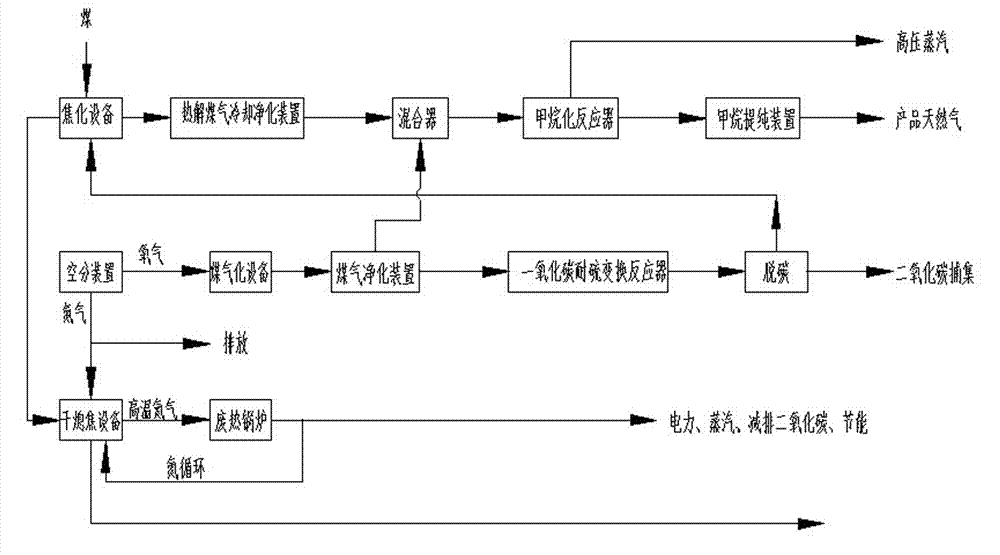

[0030] see figure 1 , implementing a coal coking and pyrolysis coal gas to natural gas process described in the present invention, including coal coking, coal gasification, gas purification, methanation, shift reaction, decarburization, carbon dioxide capture, air separation, CDQ and heat recovery process.

[0031] Among them, the utilization of gasification gas is divided into two parts, one part is used to replenish carbon in the pyrolysis gas methanation reaction system, and the other part is purified, transformed and decarbonized to produce hydrogen for coke oven heating.

[0032]In the process method, gasification coal gas is used as a carbon source to replenish carbon in the pyrolysis coal gas methanation reaction system.

[0033] The methanation reactor of this process is an isothermal bed reactor or an adiabatic bed reactor. The purification of methane adopts a pressure swing adsorption (PSA) device or a low-temperature methanol elution device. Because the methanati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com