Composite slagging agent for making semisteel, and preparation method and using method thereof

A composite slagging agent and slagging agent technology, applied in the field of metallurgy, can solve the problems of easy slag splashing, re-drying, and poor dephosphorization effect, and achieve the effects of reducing pressure, good effect, and reducing consumption of steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

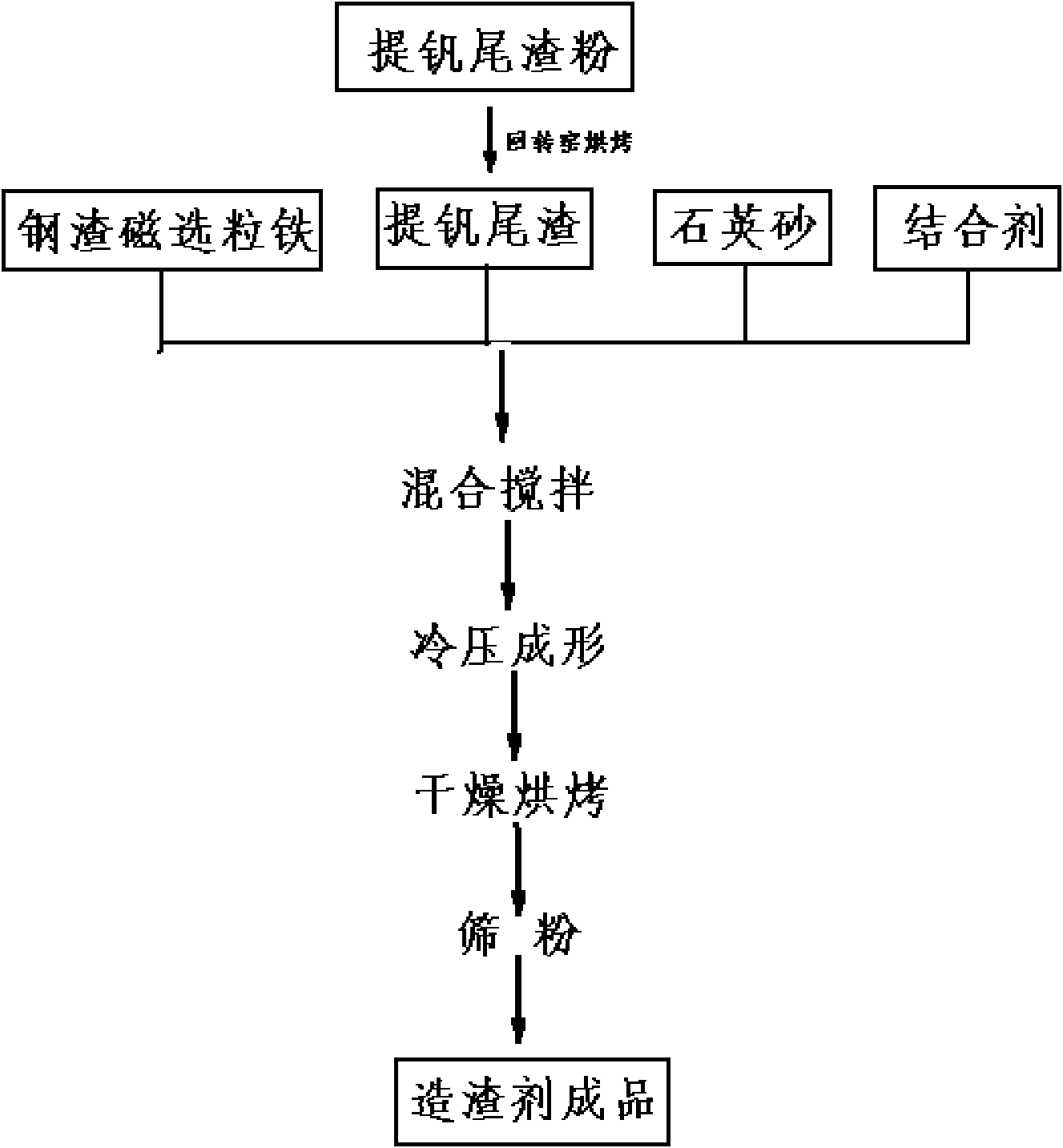

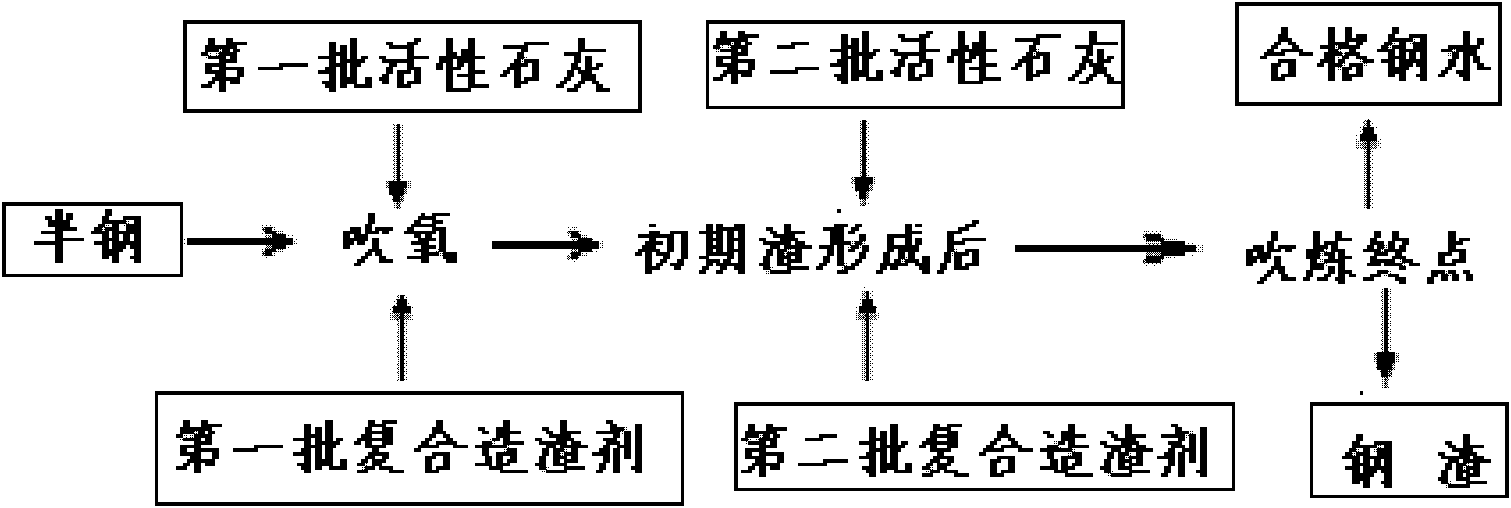

Method used

Image

Examples

Embodiment 1

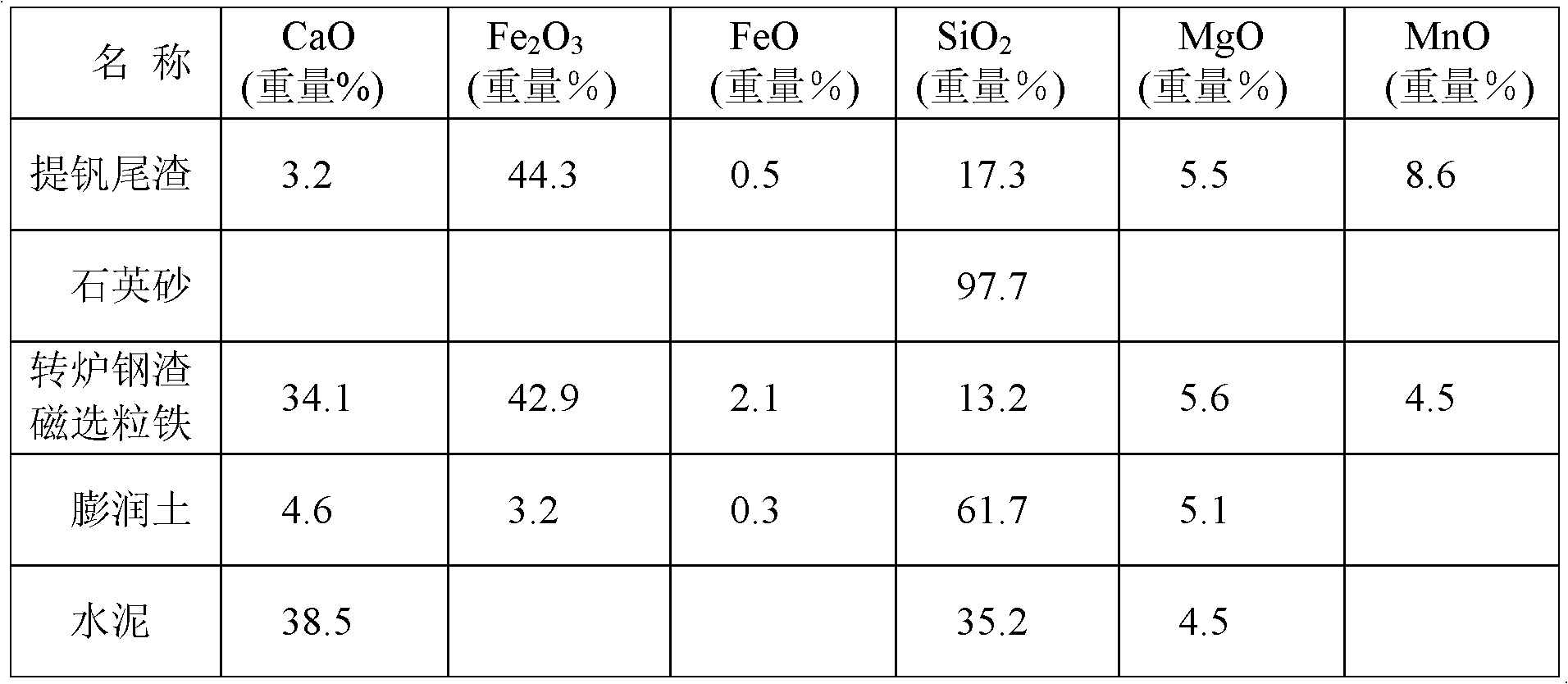

[0055] Put the vanadium extraction tailings, quartz sand, converter steel slag magnetically separated granulated iron, bentonite, and cement in Table 1 into the roller sand mixer at a mass ratio of 60:12:18:6:4, mix and stir, stir evenly and add to In the symmetrical ball press machine, adjust the pressure of the symmetrical ball press machine to 30Mpa to extrude spherical particles with a diameter of 20-50mm. The spherical particles are baked with a belt dryer at a baking temperature of 175°C and after baking for 78 minutes A composite slagging agent for pellets and semi-steel steelmaking is obtained. After testing, Fe in the obtained pellet semi-steel steelmaking composite slagging agent 2 O 3 Content, FeO content, MnO content, SiO 2 The content, CaO content and MgO content are shown in Table 3. It can be seen that the iron oxide content of the composite slagging agent prepared by the present invention is appropriate, thereby overcoming the defect that the slag is easy to spl...

Embodiment 2

[0058] Put the vanadium extraction tailings, quartz sand, converter steel slag magnetically separated granular iron, bentonite, and cement in the above table 1 into the roller sand mixer at a mass ratio of 70:10:10:6:4, mix and stir, stir evenly and then add In the symmetrical ball press, adjust the pressure of the symmetrical ball press to 35Mpa, extrude spherical particles with a diameter of 20-50mm, and bake the spherical particles with a belt dryer at a baking temperature of 180°C and baking for 85 minutes After that, the pellets and semi-steel steelmaking composite slagging agent are obtained. After testing, Fe in the obtained pellet semi-steel steelmaking composite slagging agent 2 0 3 Content, FeO content, MnO content, SiO 2 The content, CaO content and MgO content are shown in Table 3. It can be seen that the iron oxide content of the composite slagging agent prepared by the present invention is appropriate, thereby overcoming the defect that the slag is easy to splash ...

Embodiment 3

[0061] Put the vanadium extraction tailings, quartz sand, converter steel slag magnetically separated granular iron, bentonite, and cement in the above table 1 into the roller sand mixer at a mass ratio of 65:15:10:6:4, mix and stir, stir evenly and then add In the symmetrical ball press, adjust the pressure of the symmetrical ball press to 40Mpa, and extrude spherical particles with a diameter of 20-50mm. The spherical particles are baked with a belt dryer at a baking temperature of 130°C and baking for 70 minutes Then the pellets, semi-steel steelmaking composite slag-making agent are obtained. After testing, Fe in the obtained pellet semi-steel steelmaking composite slagging agent 2 O 3 Content, FeO content, MnO content, SiO 2 The content, CaO content and MgO content are shown in Table 3. It can be seen that the iron oxide content of the composite slagging agent prepared by the present invention is appropriate, thereby overcoming the defect that the slag is easy to splash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com