Method for preparing indium-enriched CuInSe2 membrane by adjusting pH value and electrodepositing

A technology of electrodeposition and thin film, which is applied in the field of new energy sources of optoelectronic materials, can solve problems such as being unable to get rid of high vacuum conditions, and achieve the effect of reducing cost, low cost, and smooth and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

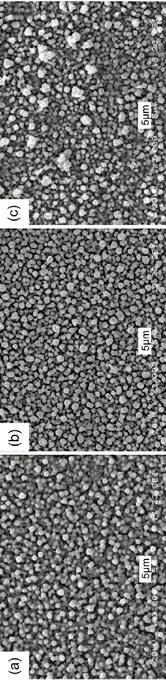

[0021] A preparation of indium-rich CuInSe by adjusting the pH value electrodeposition 2 The method of thin film, this method is: in the electrolyte solution that contains copper, indium, selenium ion (electrolyte solution composition is 6.48mmol / L CuSO 4 、50mmol / L In 2 (SO4) 3 , 20mmol / L H 2 SeO 3 , 0.5mol / L KCl and 0.5mol / L sodium citrate, deionized water is used when preparing the electrolyte); at room temperature, the pH value of the electrolyte is adjusted to 2.0 with 10% sulfuric acid by mass percentage, and then the cathode substrate Copper indium selenium prefabricated film was prepared by constant potential electrodeposition (electrodeposition adopts three-electrode electrodeposition system, using Pt mesh as counter electrode (anode), saturated calomel electrode as reference electrode, ITO conductive glass as working electrode (cathode) ), the deposition potential is -0.6 V, and the deposition time is 30 minutes). After drying, the prefabricated film is placed in ...

Embodiment 2

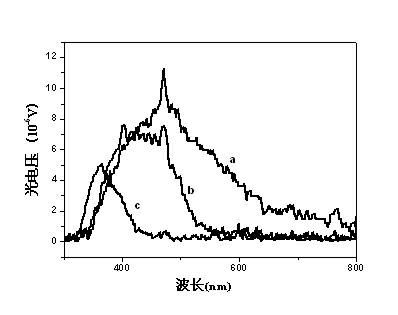

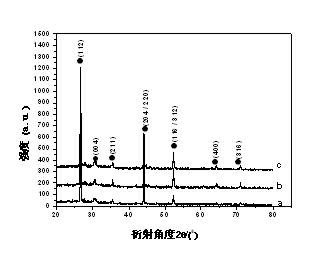

[0023] The pH value of the electrolyte was changed from 2.0 to 1.7, and other preparation conditions were the same as in Example 1. The surface of the prepared copper indium selenide thin film is smooth and dense (see figure 1 In b), Cu / In=0.97, Se / (Cu+In) =0.85, see specific performance figure 2 and image 3 .

Embodiment 3

[0025] The pH value of the electrolyte was changed from 2.0 to 1.5, and other preparation conditions were the same as in Example 1. The smoothness of the copper indium selenium thin film that makes is compared with embodiment 1 and embodiment 2 slightly worse (see figure 1 Middle c), Cu / In=1.03, Se / (Cu+In) =0.82, see specific performance figure 2 and image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com