Anti-static device

An anti-static and device technology, applied in the direction of electric solid devices, electrical components, piezoelectric devices/electrostrictive devices, etc., can solve the problems of not being able to withstand high temperature, pollution, restricting product promotion, etc. Improve thixotropy and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

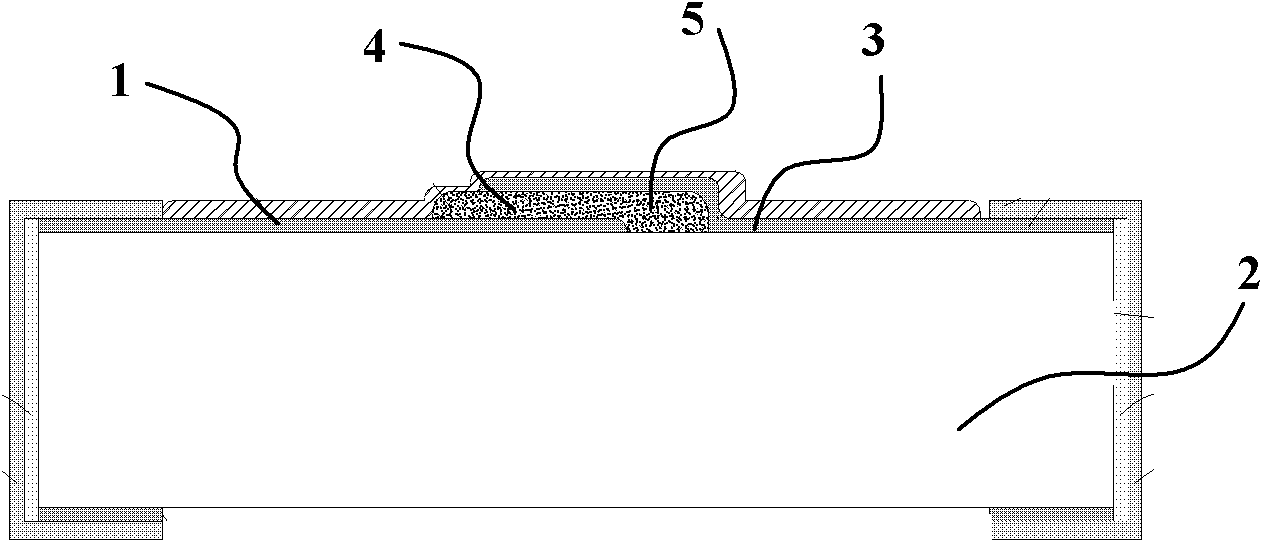

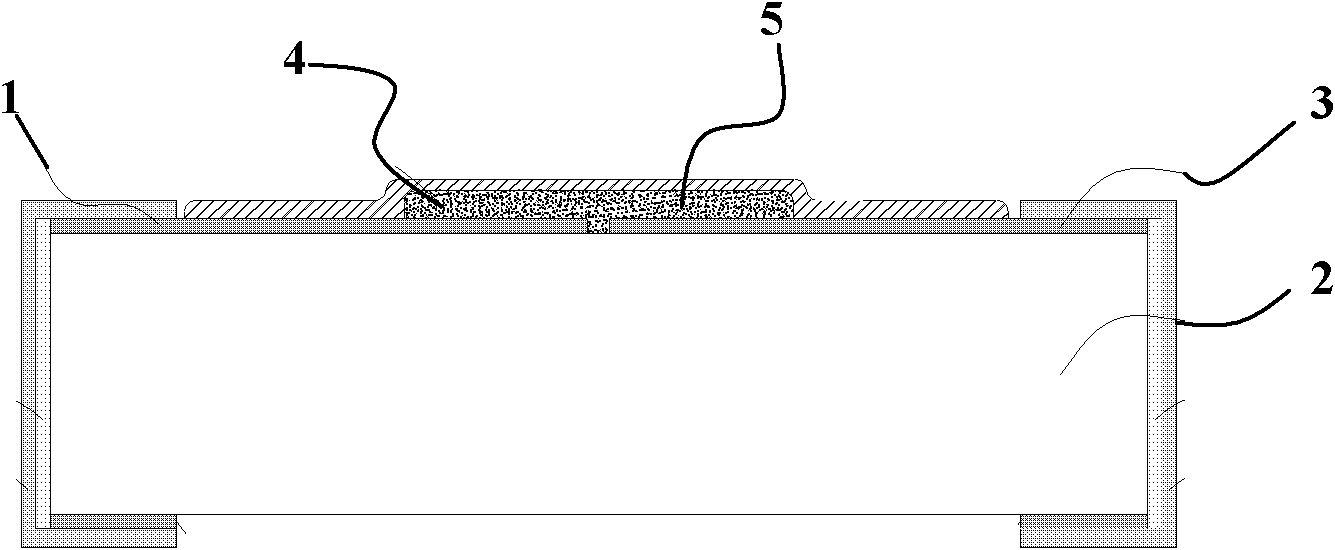

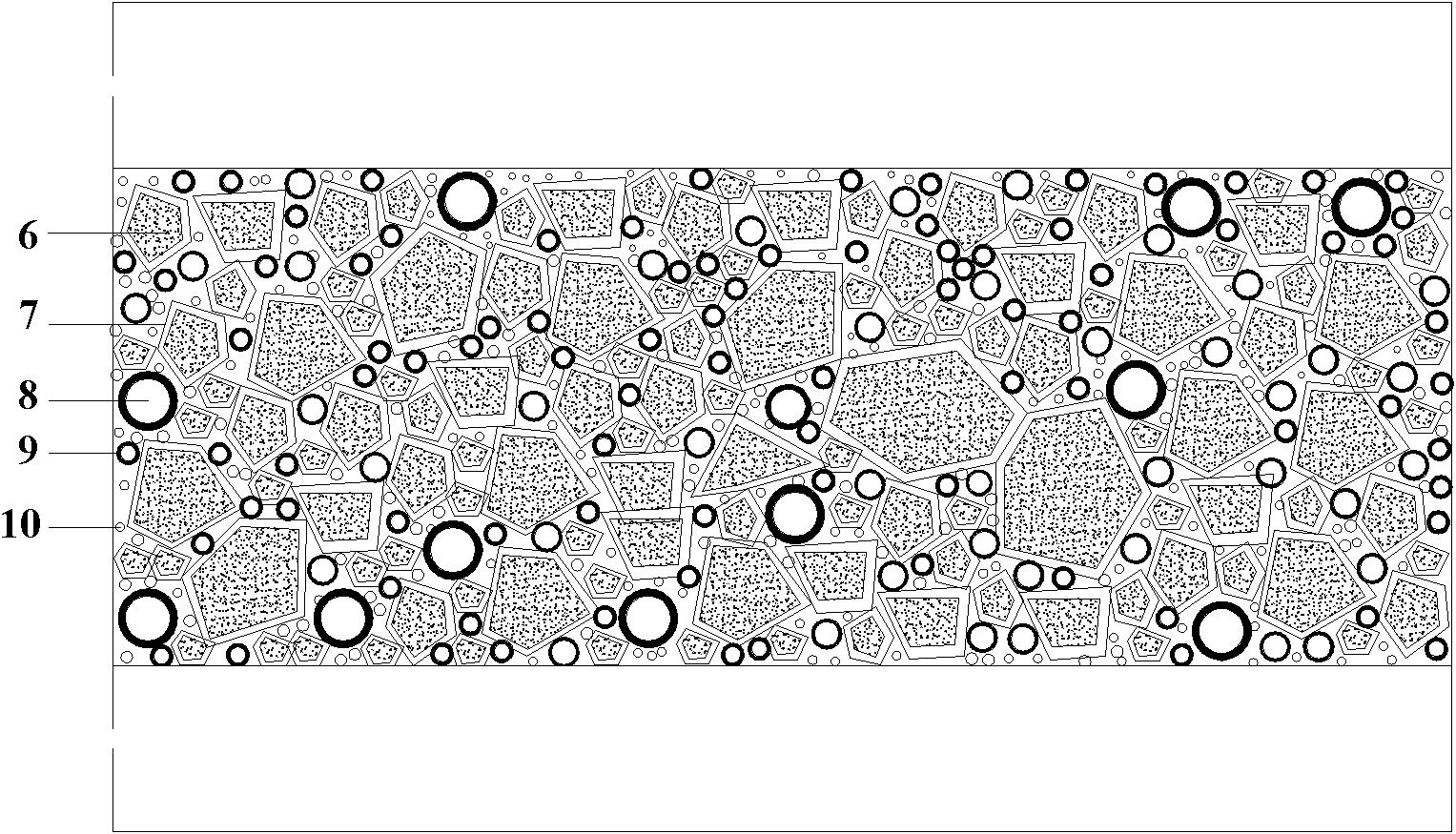

[0059] Embodiments 1 to 5: a kind of antistatic device, such as the attached Figure 1-3 , the antistatic device is provided with a substrate 2 printed with a first metal layer 1 and a second metal layer 3 encapsulated by a protective layer, and a micro gap 4 is left between the substrate 2 of the first metal layer 1 and the second metal layer 3 , the micro-gap 4 is coated with a pressure-sensitive material layer 5, and the first metal layer 1 and the second metal layer 3 are connected through the pressure-sensitive material layer 5; the protective layer is an epoxy layer or a glass layer; The pressure-sensitive material layer 5 is prepared by the following process: including the following steps:

[0060] Step 1. Prepare the glass-coated raw material. The formula of the glass-coated raw material is mainly composed of the following materials in percentage by mass, as shown in Table 1:

[0061] Table 1

[0062]

calcium isopropoxide

Tributyl borate

Aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com