Modularized multilevel flexible DC (direct current) transmission valve base control equipment

A valve-based control equipment and flexible DC technology, which is applied in the direction of parallel operation of DC power supplies, DC network circuit devices, electrical components, etc., can solve the problem of not meeting the control and protection requirements of modular flexible DC transmission valves, and not having real-time control of different sub-modules Capacitance, capacitor voltage balance control is difficult to achieve and other issues, to shorten the transmission and processing time, improve the reliability of power supply, and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

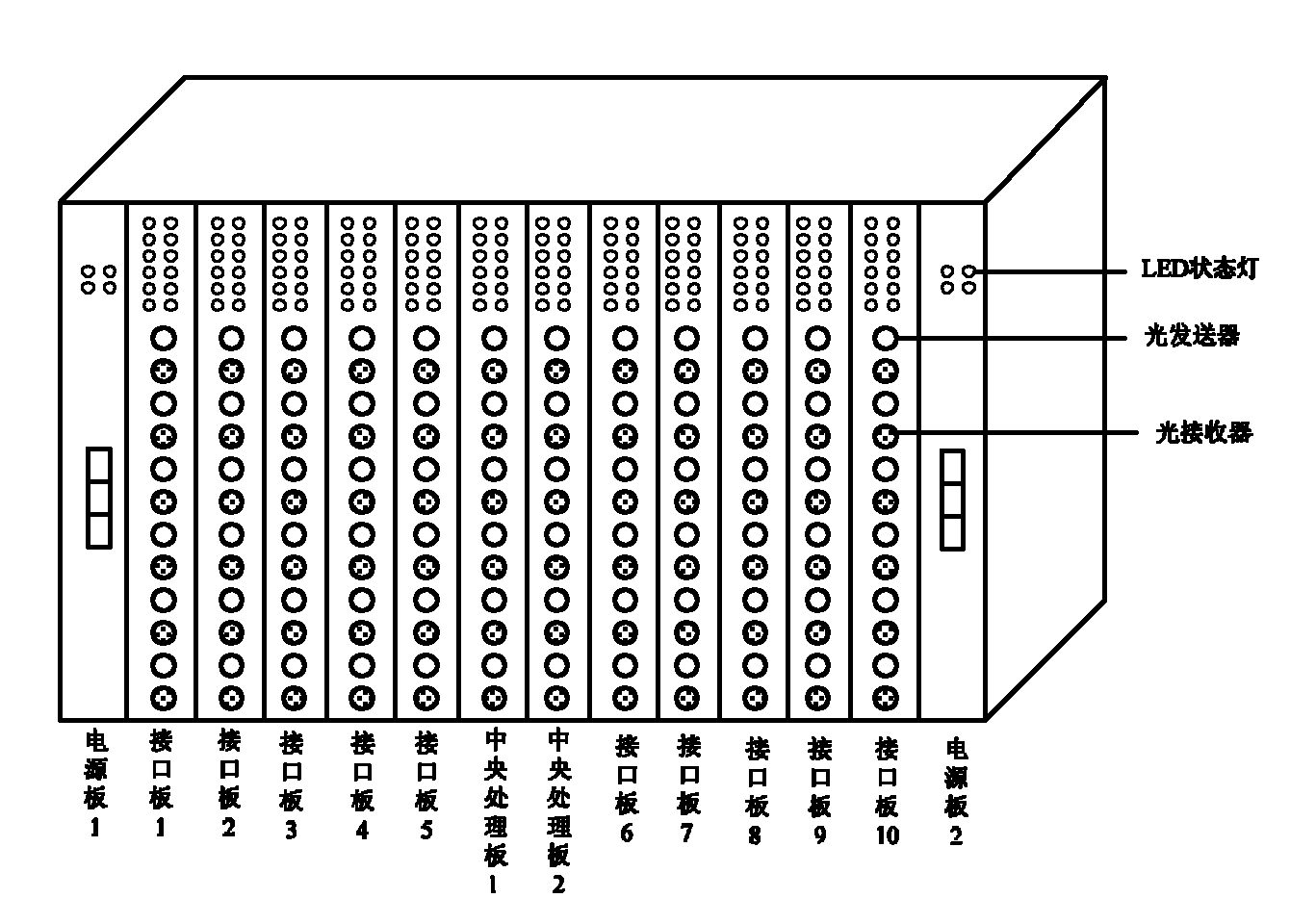

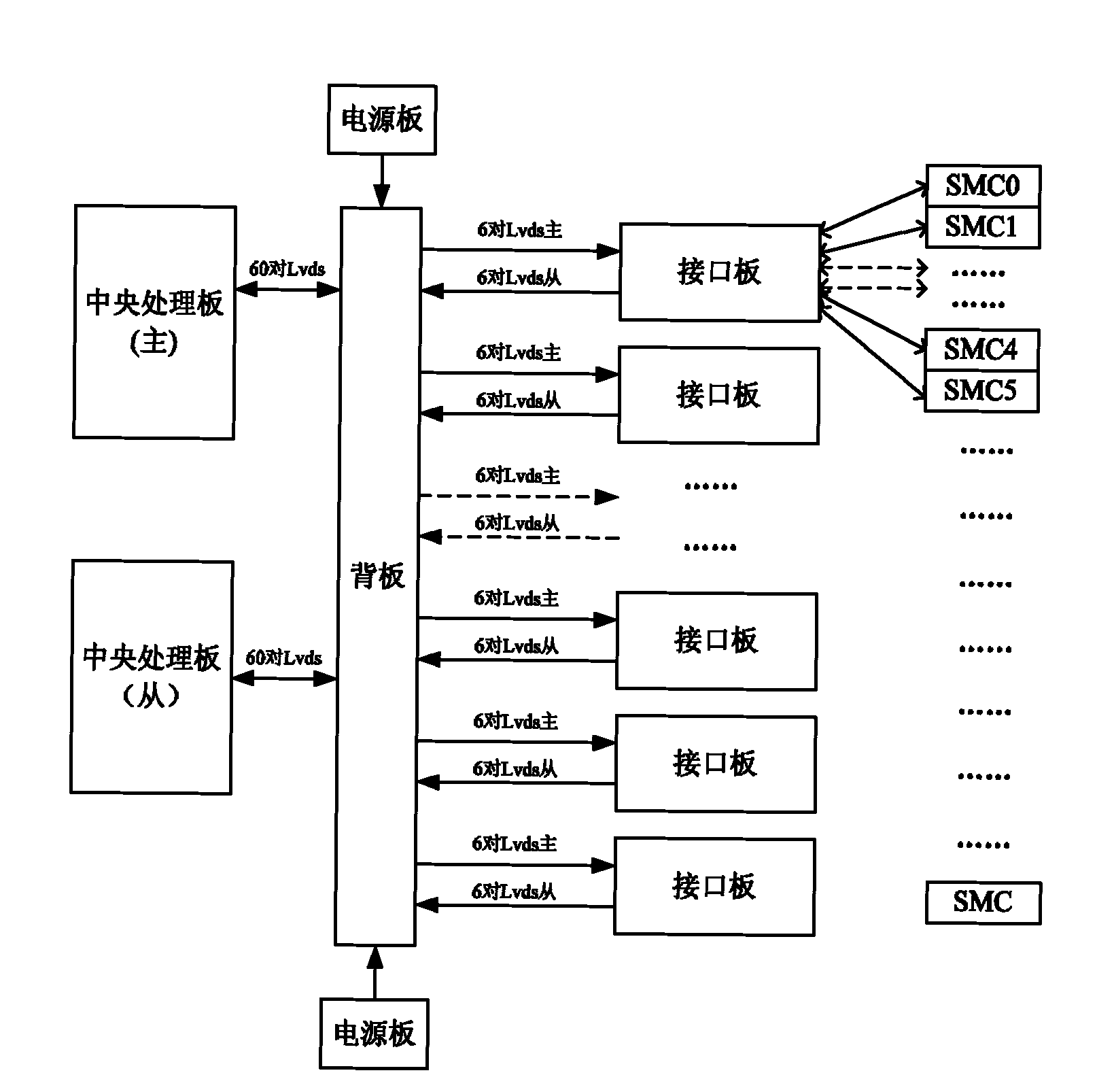

[0027] figure 1 Among them, the VBC control box hardware adopts the configuration mode of 2 power supply boards, 2 central processing boards, and 10 interface boards, and all boards transmit voltage and signals through the backplane. The functions of each board are as follows:

[0028] Power board: Convert DC110V or DC220V power supply of converter station to 5V or 15V power supply for central processing board and interface board. Wherein, the power board is hot-swappable, that is, in the power-on state, if the power board fails, the power board can be directly pulled out from the chassis.

[0029] Central processing board: realize valve control and protection algorithm, data collection and data communication functions.

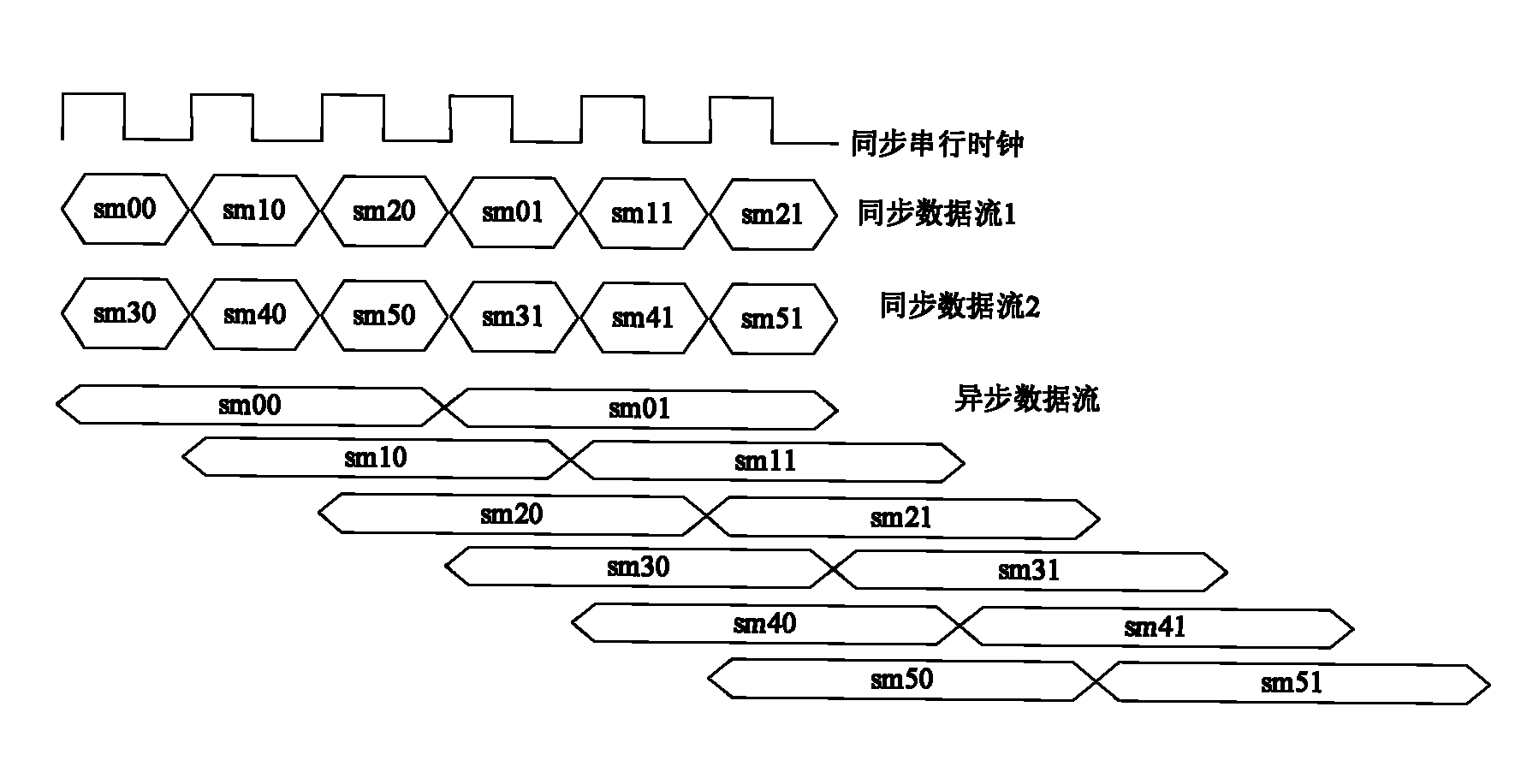

[0030] Interface board: realize the data collection and preprocessing of the sub-module of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com