Preparation method of high-purity breviscapinun material used by breviscapinun injection

A high-purity technology of breviscapine, which is applied in the preparation of sugar derivatives, chemical instruments and methods, and medical preparations containing active ingredients, etc., can solve the high-level problems of related substances, achieve enhanced curative effect, reduce the content of related substances, and ensure safety sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

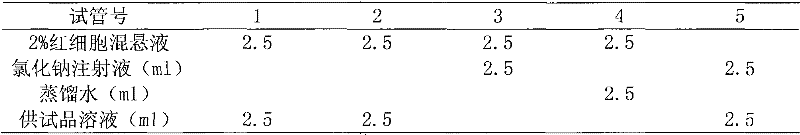

Image

Examples

Embodiment 1

[0022] Take the crude product of breviscapine and fully dissolve it with an appropriate amount of water, adjust the pH value of the solution to 4, and dissolve it completely, then add ethanol solution to make the ethanol concentration reach 50%, let it stand overnight, precipitate and filter, and then dissolve it with ethanol solution to make it The concentration of ethanol reaches 20%, the pH value is adjusted to 1, the precipitate is fully stirred and precipitated, the precipitate is precipitated after standing, filtered, the precipitate is washed with purified water to neutrality, and then ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 10,000, the ultrafiltration The filtrate was concentrated under reduced pressure and dried in vacuo to obtain high-purity scutellarin.

[0023] The high-purity breviscapine raw material is compatible with glucose or sodium chloride to prepare breviscapine glucose injection and breviscapine sodium chloride inj...

Embodiment 2

[0026] Take the crude product of breviscapine and fully dissolve it with an appropriate amount of water, adjust the pH value of the solution to 5, and dissolve it completely, then add ethanol solution to make the ethanol concentration reach 55%, let it stand overnight, precipitate and filter, and then dissolve it with ethanol solution to make it The concentration of ethanol reaches 25%, the pH value is adjusted to 1-3, the precipitate is fully stirred and precipitated, the precipitate is precipitated after standing, filtered, the precipitate is washed with purified water to neutrality, and then ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 20,000. Concentrate the ultrafiltrate under reduced pressure and dry it in vacuum to obtain high-purity scutellarin.

[0027] The high-purity breviscapine raw material is compatible with glucose or sodium chloride to prepare breviscapine glucose injection and breviscapine sodium chloride injection. The spe...

Embodiment 3

[0030] Take the crude product of breviscapine and fully dissolve it with an appropriate amount of water, adjust the pH value of the solution to 6, and make it completely dissolved, then add ethanol solution to make the ethanol concentration reach 60%, let it stand overnight, precipitate and filter, and then dissolve it with ethanol solution to make it The concentration of ethanol reaches 30%, the pH value is adjusted to 2, the precipitate is fully stirred and precipitated, the precipitate is precipitated after standing, filtered, the precipitate is washed with purified water to neutrality, and then ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 30,000, the ultrafiltration The filtrate was concentrated under reduced pressure and dried in vacuo to obtain high-purity scutellarin.

[0031] The high-purity breviscapine raw material is compatible with glucose or sodium chloride to prepare breviscapine glucose injection and breviscapine sodium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com