Synthesis method of high-purity methyl 5-hydroxy-2-methyl benzoate

A technology of methyl toluate and a synthesis method, applied in the field of synthesis of methyl 5-hydroxy-2-methylbenzoate, can solve problems such as being difficult to enlarge, achieve easy operation, low production equipment requirements, and economical The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

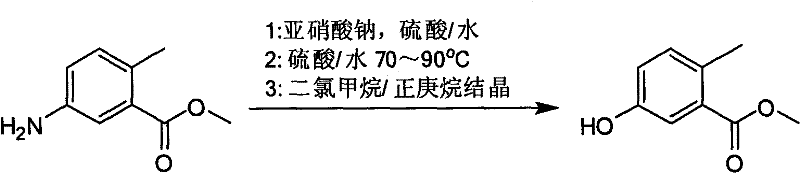

Image

Examples

example 1

[0011] Methyl 5-hydroxy-2-methylbenzoate

[0012] Dissolve methyl 5-amino-2-methylbenzoate (100g, 0.6mol) in 800mL (~2.55M) sulfuric acid solution at 5~10°C, stir for about 10min, all the solids are dissolved, and the temperature of the solution drops to 0~ 5°C, slowly add 334mL of 11.5% sodium nitrite solution dropwise, control the temperature at 0-5°C during the dropping process, react at 0-5°C for 1 hour after the dropwise addition, add the reaction solution to the Hydrolyze in 722mL (~0.86M) sulfuric acid solution, pay attention to the dropping speed, control the temperature at 70-80°C during the dropping process, react at 70-90°C for 35min after dropping, cool to 0-5°C to crystallize, Stir at ~5°C for 3h and filter.

[0013] Purification of methyl 5-hydroxy-2-methylbenzoate

[0014] Dissolve the crude product in 200mL of dichloromethane, wash with 300mL of water three times, slowly drop 400mL of heptane into dichloromethane to precipitate a solid, stir at 5-15°C for 12h...

example 2

[0016] Methyl 5-hydroxy-2-methylbenzoate

[0017] Dissolve methyl 5-amino-2-methylbenzoate (100g, 0.6mol) in 800mL (~2.55M) sulfuric acid solution at 5~10°C, stir for about 10min, all the solids are dissolved, and the temperature of the solution drops to 0~ 5°C, slowly add 334mL of 11.5% sodium nitrite solution dropwise, control the temperature at 0-5°C during the dropping process, react at 0-5°C for 1 hour after the dropwise addition, and add the reaction solution to the Hydrolyze in 720mL (~0.86M) sulfuric acid solution, pay attention to the dropping speed, control the temperature at 80-90°C during the dropping process, react at 70-90°C for 45min after dropping, cool to 0-5°C to crystallize, Stir at ~5°C for 3h and filter.

[0018] Purification of methyl 5-hydroxy-2-methylbenzoate

[0019] Dissolve the crude product in 200mL of dichloromethane, wash with 300mL of water three times, slowly drop 400mL of heptane into dichloromethane to precipitate a solid, stir at 5-15°C for...

example 3

[0021] Methyl 5-hydroxy-2-methylbenzoate

[0022] Dissolve methyl 5-amino-2-methylbenzoate (100g, 0.6mol) in 800mL (~2.55M) sulfuric acid solution at 5~10°C, stir for about 10min, all the solids are dissolved, and the temperature of the solution drops to 0~ 5°C, slowly add 334mL of 11.5% sodium nitrite solution dropwise, control the temperature at 0-5°C during the dropping process, react at 0-5°C for 1 hour after the dropwise addition, and add the reaction solution to the Hydrolyze in 720mL (~0.86M) sulfuric acid solution, pay attention to the dropping speed, control the temperature at 70-90°C during the dropping process, react at 70-90°C for 60min after dropping, cool to 0-5°C to crystallize, Stir at ~5°C for 3h and filter.

[0023] Purification of methyl 5-hydroxy-2-methylbenzoate

[0024] Dissolve the crude product in 150 mL of dichloromethane, slowly drop 300 mL of heptane into dichloromethane to precipitate a solid, stir at 5-15°C for 14 h, filter, and then use dichloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com