Method for separating and purifying kainic acid through controllable multichannel electroosmosis

An electrodialysis and multi-channel technology, applied in electrodialysis, organic chemistry, etc., can solve the problems of high price, difficulty in ensuring activity, and high cost, and achieve the effects of increasing speed, realizing separation, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

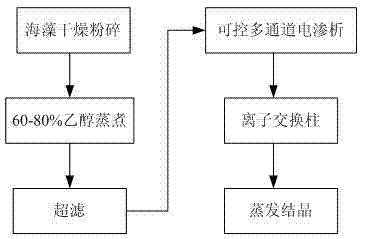

[0027] Example 1: A method for separating and purifying kainic acid by controllable multi-channel electrodialysis, comprising the steps of:

[0028] A. Collect partridge or sea algae, dry and crush into seaweed particles;

[0029] B, the seaweed particles are reflux cooked twice with 60% ethanol with a mass concentration, and the filtrate is combined; the mass ratio of ethanol to seaweed particles is 2:1

[0030] C, the filtrate is filtered with ultrafiltration to remove particulate impurities;

[0031] D. Use controllable multi-channel electrodialysis to remove salts, polysaccharide compounds and other impurities in the filtrate;

[0032] E. Use an ion exchange resin column for further separation and purification to remove impurities similar in nature to kainic acid;

[0033] F. Vacuum drying and crystallization to obtain kainic acid.

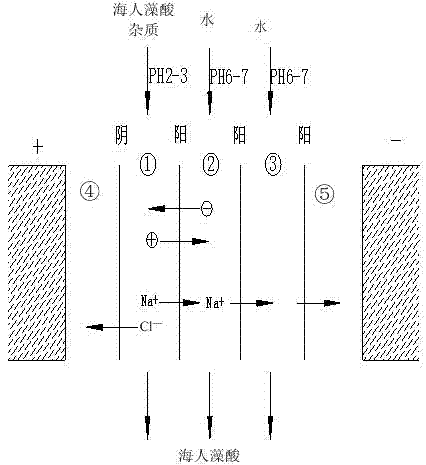

[0034] Controllable multi-channel electrodialysis consists of a plate, a separator, an anion exchange membrane, and a cation exchange me...

Embodiment 2

[0035] Example 2: The method for separating and purifying kainic acid with controllable multi-channel electrodialysis is different from the example in that in step B, the seaweed particles are refluxed and cooked 4 times with ethanol with a mass concentration of 80%, and the filtrate is combined; the ethanol and seaweed particles Mass ratio is 4:1, and others are with embodiment 1. The difference from Example 1 is that the controllable multi-channel electrodialysis channel ① enters the unpurified stock solution containing kainic acid, the pH value is controlled at 2.5, and the channel ② enters NaNO 3 Solution, pH 7, channel ③ into NaNO 3 solution, pH 7. Adjust the pH value of the channel by adding hydrochloric acid or NaOH solution, and add it while measuring the pH value until the pH reaches the requirement.

Embodiment 3

[0036] Example 3: Method for separating and purifying kainic acid by controllable multi-channel electrodialysis: figure 2 It is a schematic diagram of the structure of controllable multi-channel electrodialysis. Controllable multi-channel electrodialysis is composed of plate, separator, anion exchange membrane and cation exchange membrane. Chamber ④ and cathode chamber ⑤, channel ① enters unpurified stock solution containing kainic acid, the pH value is controlled at 2.0, channel ② enters NaNO 3 solution, pH 6.5, channel ③ into NaNO 3 solution, pH 6.5. Channel ① is filled with cation exchange resin (001x7, purchased from Nankai University Chemical Plant), channels ② and ③ are added with mixed bed ion exchange resin (anion exchange resin is 201x7, purchased from Nankai University Chemical Plant), and the mass ratio of anion and cation exchange resins is 1:1. figure 1 It is a process flow diagram of the present invention. It can be seen from this figure that the partridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com