H-shaped carbonization furnace and method for producing biomass activated carbon and carbonized combustion gas by using same

A technology of carbonization furnace and gas, which is applied in the direction of chemical instruments and methods, biofuels, carbon compounds, etc. It can solve the problem that the quality of carbonization products cannot be guaranteed, the strict sealing of the gasification furnace cannot be guaranteed, and the furnace mouth cannot be sealed and fed, etc. problems, to achieve the effect of improving farmers' living conditions, improving farmers' living conditions, and increasing farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

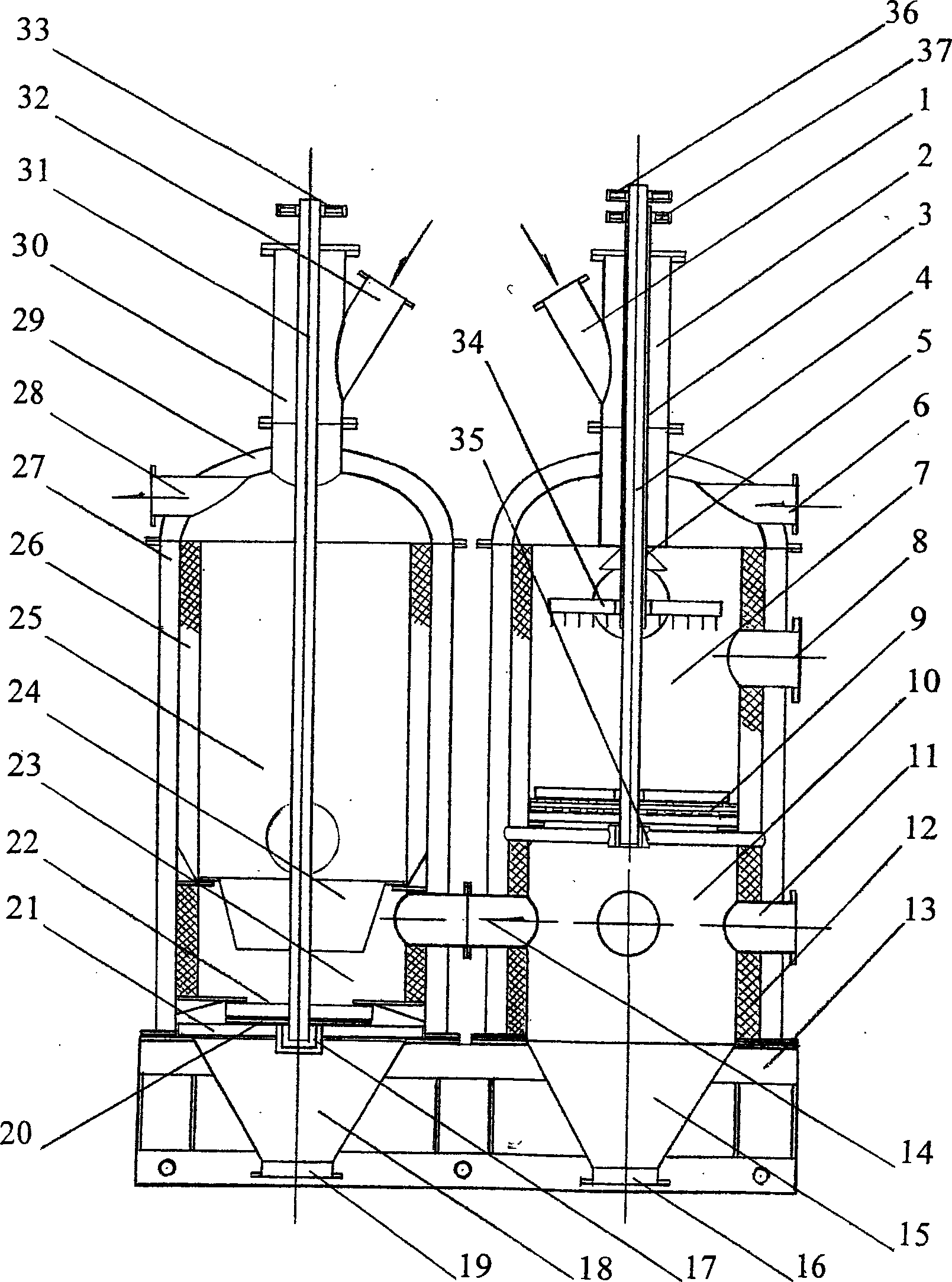

Embodiment 1

[0016] The bamboo waste, nut shells, wood chips and other materials are crushed into a cylindrical granular material with a diameter of 6-10mm and a length of 30-50mm. The gasified material is added through the middle feeding port 1 of the feeding pipe 2 on the upper furnace roof. The upper part of the furnace gasification chamber 7 with a diameter of 1.2 meters in the furnace and a furnace body height of 4.8 meters, and then the carbonized material is fed into the furnace through the middle sealed feeding port 32 of the sealed feeding pipe 30 arranged at the upper part of the furnace top 29 of the carbonization chamber in the furnace In the inner carbonization chamber 25, after the carbonization material is filled, the sealed feeding port 32 is closed, and the negative pressure Roots blower set outside the furnace is started during operation, and the ignition furnace door 8 set on the upper part of the gasification chamber 7 in the furnace is opened. Ignite the gasification mat...

Embodiment 2

[0023] Rice straw, wheat stalks, corn stalks and other materials are pulverized into small cylindrical particles with a diameter of 6-10 mm and a length of 30-50 mm. The materials are gasified through the middle feeding port 1 of the feeding pipe 2 on the upper furnace roof. Add into the upper part of the furnace gasification chamber 7 with a diameter of 1.8 meters in the furnace and a furnace body height of 5.3 meters, and then add the carbonized materials through the middle sealed feeding port 32 of the sealed feeding pipe 30 arranged at the upper part of the top 29 of the carbonization chamber in the furnace In the furnace carbonization chamber 25, after the carbonization material is filled, the sealed feeding port 32 is closed, and the negative pressure Roots blower set outside the furnace is started during operation, and the ignition furnace door 8 set on the upper part of the gasification chamber 7 in the furnace is opened. Ignite the gasification material in the upper par...

Embodiment 3

[0030] The materials such as cotton stalks, bean stalks, branches and other materials are crushed and formed into cylindrical granular materials with a diameter of 6-10mm and a length of 30-50mm. The gasified materials are added through the middle feeding port 1 of the feeding pipe 2 on the upper furnace roof. The upper part of the furnace gasification chamber 7 with a diameter of 2.4 meters in the furnace and a furnace body height of 5.3 meters, and then the carbonized materials are fed into the furnace through the middle sealed feeding port 32 of the sealed feeding pipe 30 arranged at the upper part of the top 29 of the carbonization chamber in the furnace In the inner carbonization chamber 25, after the carbonization material is filled, the sealed feeding port 32 is closed, and the negative pressure Roots blower set outside the furnace is started during operation, and the upper ignition furnace door 8 set in the gasification chamber 7 in the furnace is opened. Ignite the gasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com