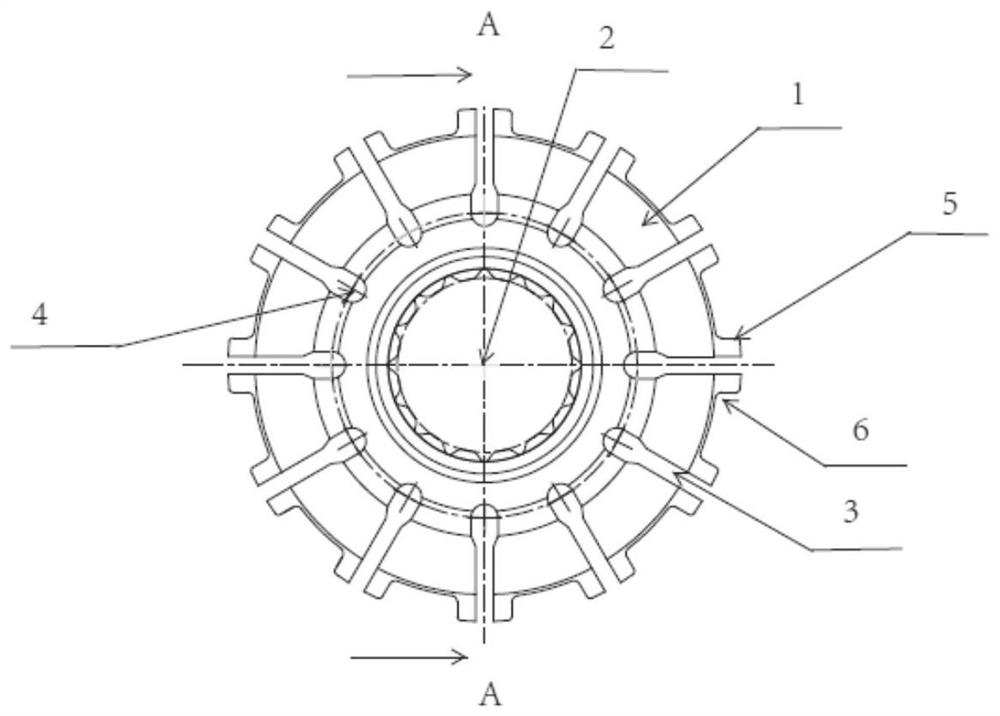

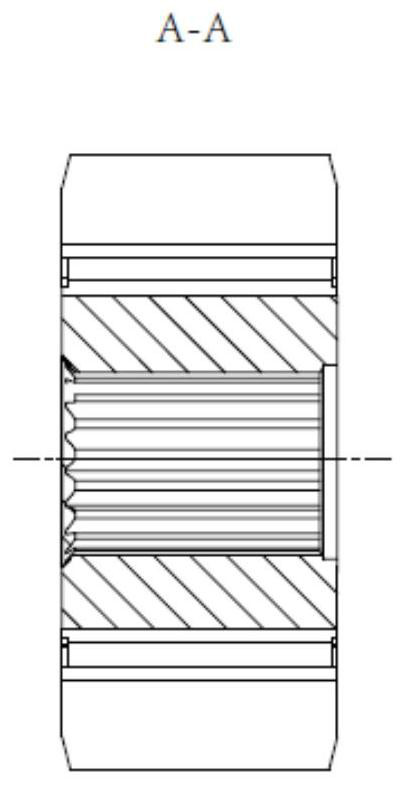

Vane type gearbox oil pump rotor and preparation method thereof

A vane type and rotor technology, which is applied in the field of vane type gearbox oil pump rotor and its powder metallurgy preparation, can solve the problems of increased vehicle weight, low efficiency, low material utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A powder metallurgy preparation method for a blade type gearbox oil pump rotor, comprising the following steps:

[0037] Step 1: Mixing: Design raw material composition and mixing; mix the raw materials evenly according to the above mass percentage.

[0038] Step 2: Warm mold pressing: Put the prepared powder metallurgy raw materials into the forming machine, put the cylindrical heating rod and thermocouple into the female mold, heat the mold to a temperature of 93°C±5°C, and the forming density is ≥7.10g / cm 3 , There is no crack at the junction of each part of the green body.

[0039] The third step: sintering hardening and tempering: sintering adopts a mesh belt type sintering hardening furnace, the sintering temperature is 1120°C, and the 2 :H 2 = Sintering in 90:10 sintering atmosphere for 30~40min, using hydrogen H in an oxygen-free environment 2 as a shielding gas. Specifically described air cooling adopts nitrogen N 2 As a cooling medium, the cooling rate is...

Embodiment 1

[0047] A powder metallurgy preparation method for a vane type transmission oil pump rotor, comprising the following steps:

[0048] (1) Mixing: design raw material composition and mixing; mix the following raw materials evenly by mass percentage: C: 0.59%; Cu: 2.2%; Mo: 1.52%, special lubricant H: 0.4%; the rest is Fe and unavoidable impurities.

[0049] (2) Warm mold compaction: Put the prepared powder metallurgy raw materials into the forming machine, put the cylindrical heating rod and thermocouple into the female mold, heat the mold to a temperature of 93°C±5°C, and the forming density is 7.10g / cm 3 , There is no crack at the junction of each part of the green body.

[0050] (3) Sintering hardening and tempering: Sintering adopts a mesh belt type sintering hardening furnace, the sintering temperature is 1120 ° C, in N 2 :H 2 = Sintering in a 90:10 sintering atmosphere for 40 minutes, using hydrogen as a protective gas in an oxygen-free environment. Specifically, the air ...

Embodiment 2

[0058] A powder metallurgy preparation method for a blade type gearbox oil pump rotor, comprising the following steps:

[0059] (1) Mixing: design raw material composition and mixing; mix the following raw materials evenly by mass percentage: C: 0.72%; Cu: 1.8%; Mo: 1.62%, special lubricant H: 0.5%; the rest is Fe and unavoidable impurities.

[0060] (2) Warm mold compaction: Put the prepared powder metallurgy raw materials into the forming machine, put the cylindrical heating rod and thermocouple into the female mold, heat the mold to a temperature of 93°C±5°C, and form a green body with a density of 7.15g / cm3. There are no cracks at the joints of each part.

[0061] (3) Sintering hardening and tempering: Sintering adopts a mesh belt type sintering hardening furnace, the sintering temperature is 1130 ° C, in N 2 :H 2 = Sintering in a 90:10 sintering atmosphere for 35 minutes, using hydrogen as a protective gas in an oxygen-free environment. Specifically, the air cooling u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com