Polarizing plate, method of manufacturing the same, optical film and image display apparatus

A manufacturing method and polarizing plate technology, applied in the direction of optics, lamination devices, polarizing elements, etc., can solve problems such as reddening, unsatisfactory durability, low transmittance, etc., achieve good dimensional stability, suppress production costs, The effect of high-speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

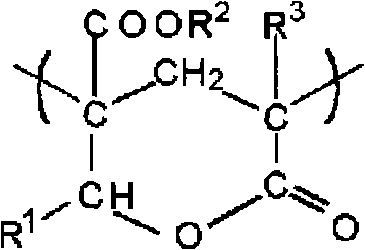

Method used

Image

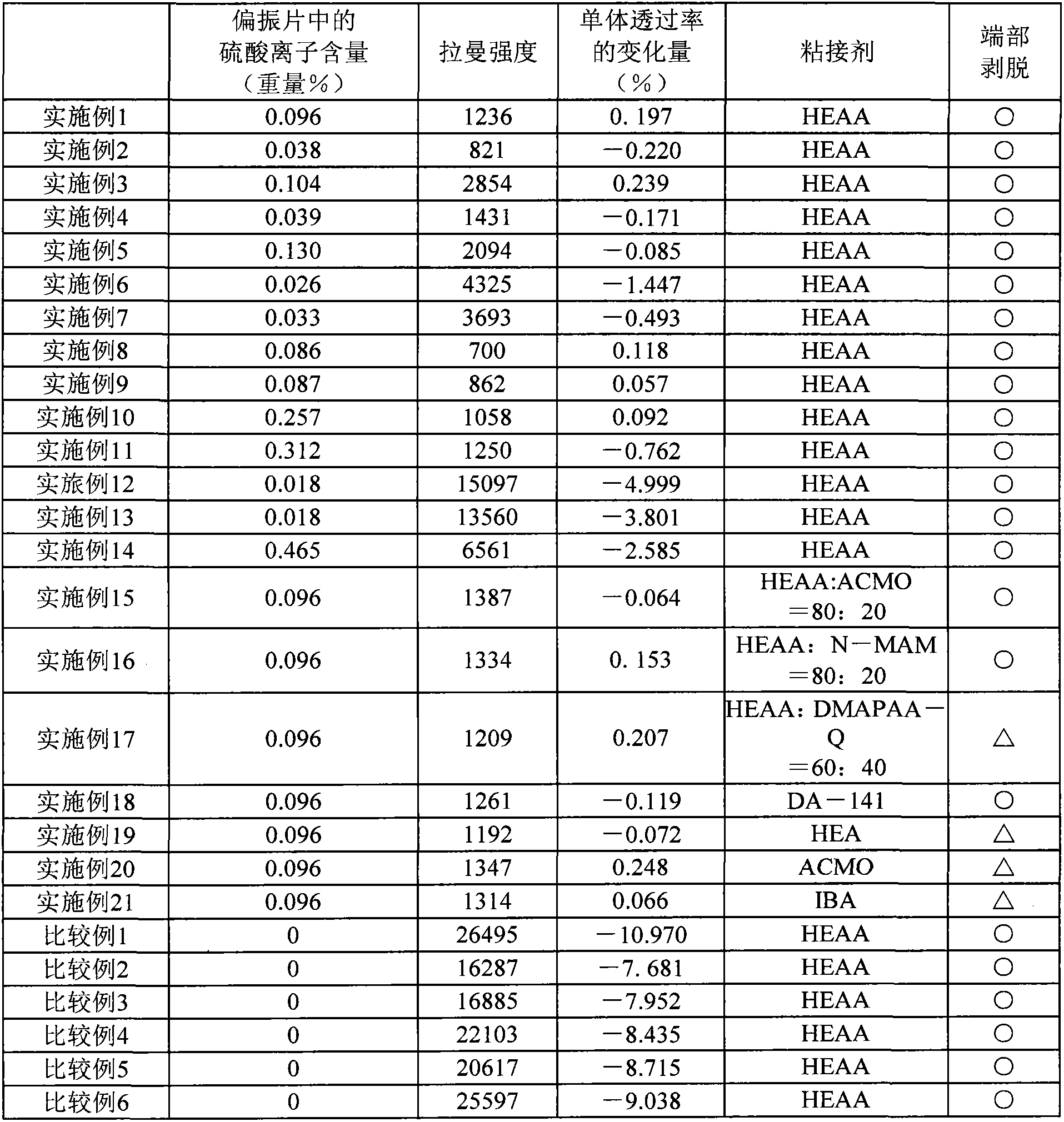

Examples

Embodiment 1

[0165] (polarizer)

[0166] Immerse a polyvinyl alcohol film with an average degree of polymerization of 2400, a degree of saponification of 99.9 mol%, and a thickness of 75 μm in warm water at 30°C for 60 seconds to swell it, and then uniaxially stretch it in water (the draw ratio is 3.5 times) ). Next, dyeing was carried out for 60 seconds in a 30°C iodine solution having a concentration of 0.3% by weight (weight ratio: iodine / potassium iodide=0.5 / 8). Then, dip for 45 seconds in the first boric acid aqueous solution (boric acid concentration is 3% by weight, potassium iodide concentration is 3% by weight) at 40°C, and then, in the second boric acid aqueous solution (boric acid concentration is 4% by weight, potassium iodide concentration 5% by weight and anhydrous sodium sulfate concentration of 2% by weight) while being immersed for 30 seconds until the total stretching ratio becomes 6 times. Then, it was immersed in 30 degreeC potassium iodide aqueous solution (potassium...

Embodiment 2

[0176] In Example 1, when preparing a polarizing plate, the anhydrous sodium sulfate in the second boric acid aqueous solution of 2% by weight was replaced with 2% by weight of zinc sulfate heptahydrate, except that it was carried out in the same manner as in Example 1 to obtain Polarizing plate.

Embodiment 3

[0178] In Example 1, when preparing a polarizing plate, the anhydrous sodium sulfate in the 2% by weight of the second boric acid aqueous solution was replaced by 2% by weight of anhydrous magnesium sulfate. plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com