New process for producing aluminum and silicon chemical products by low-grade bauxite or kaolin raw material based on alkaline method

A low-grade bauxite and kaolin technology, applied in the direction of alumina/aluminum hydroxide, aluminum halide, silicon oxide, etc., can solve the problems of poor whiteness of polyaluminum chloride, large waste slag discharge, low component utilization rate, etc. , to increase the selling price, increase the dissolution rate, and improve the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

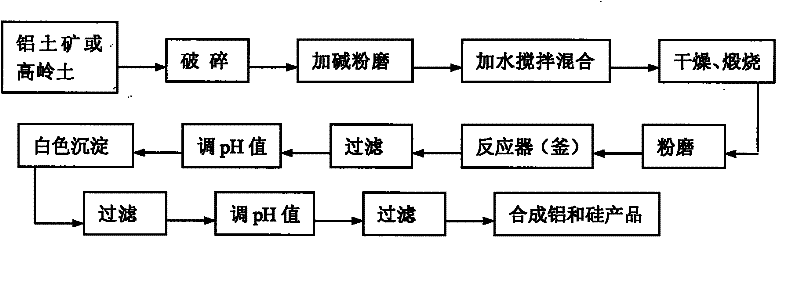

[0015] The mined massive bauxite or kaolin should first be crushed into fine particles, and then be ground together with strong alkali to improve their homogenization effect and fineness. After grinding, add a small amount of water according to the situation, and mix it evenly in the mixer to form moist loose particles. After drying and calcination in the kiln, the material is sintered into a gray-white material, and then it is ground into a fine powder. materials. Put this powdery material into a reactor (kettle), add an appropriate amount of water, stir, and increase the temperature at the same time. After the silicon and aluminate in the powdery material are fully dissolved, send it to a filter device to separate the dissolved Silicon, aluminates and insoluble matter. The alkalinity of silicon and aluminate solution is high, acid can be added to lower the pH value until white precipitate is completely formed. After filtering the white precipitate to separate part of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com