Treatment process method for wastewater from abscisic acid production

A technology for waste water production and treatment process, applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

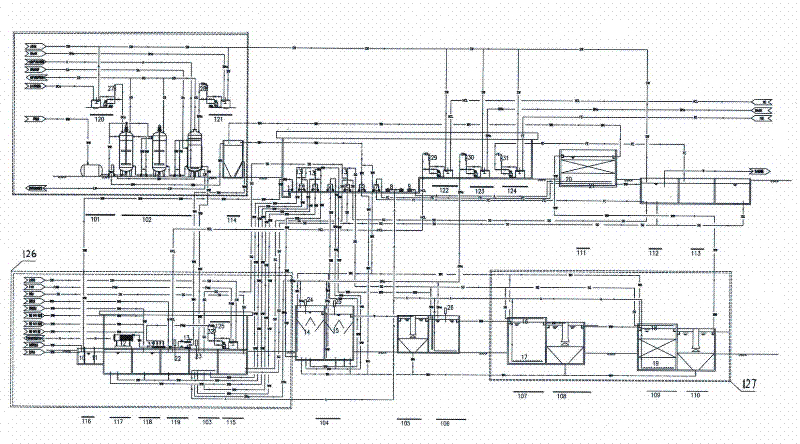

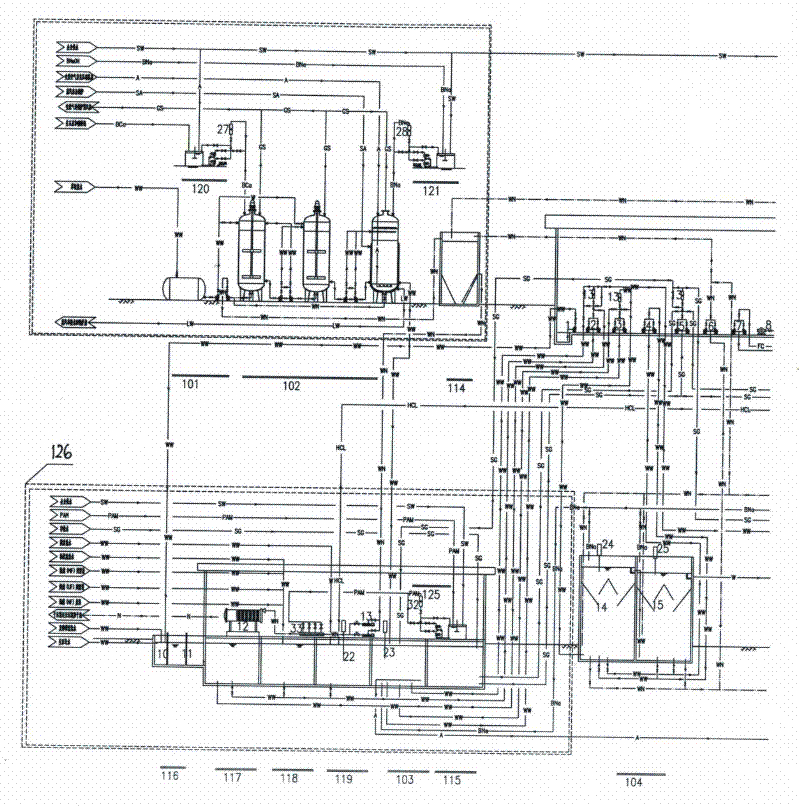

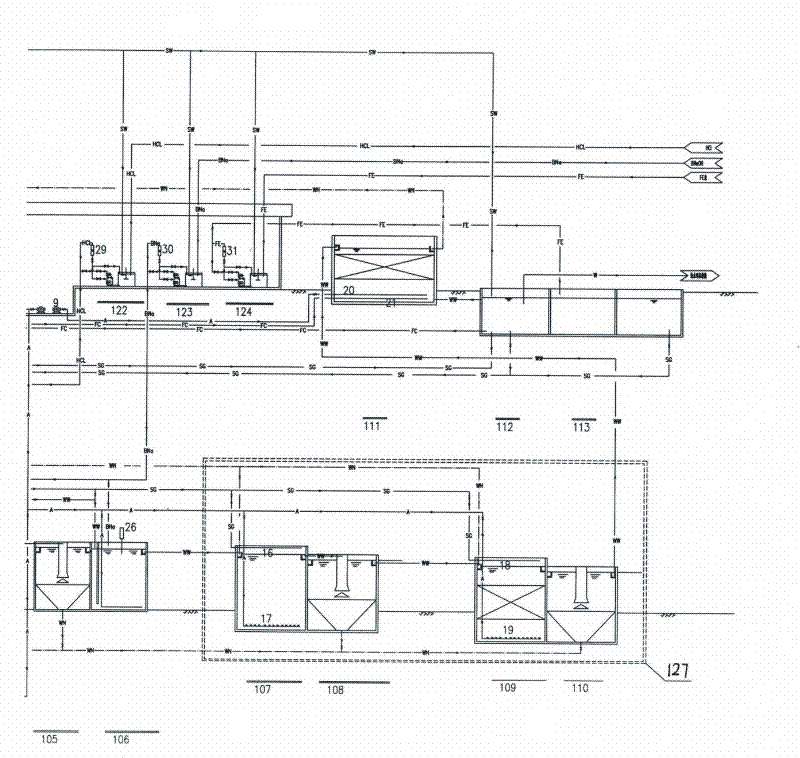

Image

Examples

Embodiment

[0091] Embodiment: process step is as follows:

[0092] 1) In view of the characteristics of the extraction wastewater, it is collected separately and stored in the extraction wastewater storage tank 101, the pH of the wastewater is about 0.4 to 2, and the SO 4 2- The content is 5000mg / L, the CODcr concentration is 100,000-150,000 mg / L, and the NH 3 -N concentration is 2000~7000mg / L, SO 4 2- The concentration is 480-38000mg / L, and it also contains extractants such as petroleum ether, ethyl acetate and butyl acetate, which are difficult to biodegrade Acidic extraction wastewater toxicity removal process and supporting equipment" complete set of process and equipment), the extraction wastewater is pumped into the comprehensive treatment system from the extraction wastewater storage tank 101, supplemented by a lime adding dispenser 120 and a caustic soda adding dispenser 121 to adjust the pH value of the wastewater To 9~10, detoxification, the sludge is pumped into the mud st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com