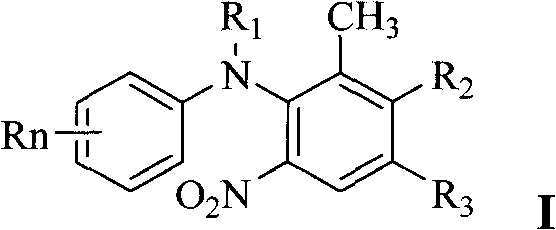

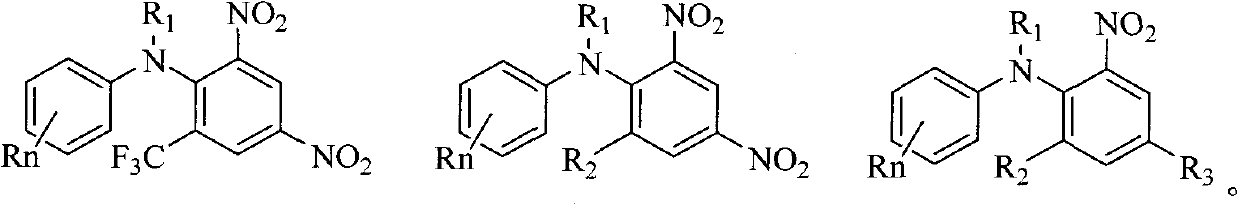

Substituted diphenylamine compounds and preparation and application thereof

A compound, diphenylamine technology, applied in the field of acaricide, insecticide, agricultural sterilization, can solve the problem of no biological activity report

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

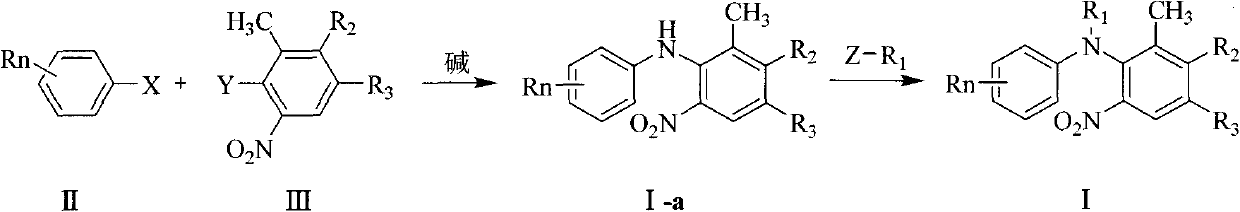

Method used

Image

Examples

example 1

[0142] Example 1: Preparation of compound 2

[0143]

[0144] Take 0.4g (0.01mol) of 60% sodium hydride in the reaction flask, wash with petroleum ether, add 20ml of tetrahydrofuran and stir, add 0.81g (0.005mol) of 2,4-dichloroaniline in batches, and stir at room temperature after adding After 30 minutes, 1.56 g (0.006 mol) of 2,6-dichloro-3,5-dinitrotoluene was dissolved in 30 ml of tetrahydrofuran and then dropped into the reaction flask. After about 30 minutes, the addition was completed, and the stirring was continued at room temperature for 5 hours. After the reaction was monitored by TLC, the reaction solution was filtered, the filtrate was desolvated under reduced pressure, and the compound was purified by column chromatography (eluent: ethyl acetate and petroleum ether (boiling range 60-90°C), volume ratio 1:20) 2. Yellow solid 1.37g, melting point 136-137°C.

[0145] 1 H-NMR (300MHz, internal standard TMS, solvent CDCl 3 ) δ (ppm): 2.14 (s, 3H), 6.53 (d, 1H), 7.17 (d, 1H...

example 2

[0146] Example 2: Preparation of compound 38

[0147]

[0148] Dissolve 0.56g (0.0015mol) of Compound 2 in 5ml of concentrated sulfuric acid (96%, the same below) and cool to 0℃, mix 0.15g of fuming nitric acid (95%) and 3ml of concentrated sulfuric acid and add to the reaction flask, continue After stirring for 5 minutes, the reaction was monitored by TLC. The reaction solution was poured into ice water. A solid precipitated out. It was filtered. The filter cake was washed with water and dried to obtain compound 38, a brown solid 0.59 g, with a melting point of 156-158°C.

[0149] 1 H-NMR (300MHz, internal standard TMS, solvent CDCl 3 ) δ (ppm): 2.09 (s, 3H), 7.66 (s, 1H), 8.01 (s, 1H), 8.60 (s, 1H), 9.75 (s, 1H).

example 3

[0150] Example 3: Preparation of compound 43

[0151]

[0152] Take 0.32g (0.008mol) of 60% sodium hydride in the reaction flask, wash with petroleum ether, add 10ml DMF and stir, add 0.83g (0.004mol) of 2,6-dichloro-4-nitroaniline in batches, add After the completion, it was stirred at room temperature for 30 minutes, and then 1.20 g (0.0048 mol) of 2,6-dichloro-3,5-dinitrotoluene was added in portions within 30 minutes, and the reaction was continued for 3 hours at room temperature. After the reaction was monitored by TLC, the reaction solution was poured into 50ml of saturated brine, extracted with ethyl acetate, and the extract was dried over anhydrous magnesium sulfate to remove the solvent under reduced pressure. Column chromatography (eluent: ethyl acetate and petroleum ether (boiling) (Range 60-90℃), volume ratio 1:10) purified to obtain compound 43, yellow solid 1.20g, melting point 157-158℃.

[0153] 1 H-NMR (300MHz, internal standard TMS, solvent CDCl 3 ) δ (ppm): 2.02 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com