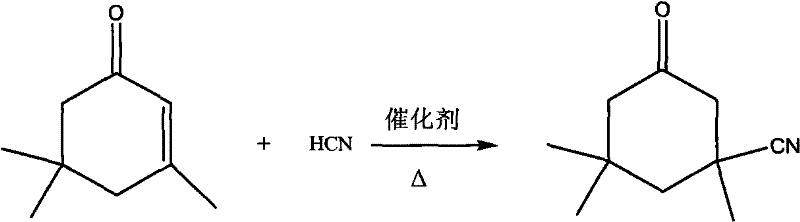

Preparation method of isophorone nitrile

A technology of isophorone nitrile and isophorone, which is applied in the field of synthesizing isophorone nitrile, can solve problems such as increasing energy consumption and procedures, cumbersomeness, and increasing equipment investment, so as to reduce material consumption, solve environmental pollution, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 400ml of strong basic exchange resin IRA-400 (Shanghai Boyao Biotechnology Co., Ltd. agent) into a cylindrical fixed-bed reactor with a length of 800mm and a diameter of 25mm for later use. Turn on the preheater and the heat tracing of the fixed bed jacket, the raw material IP (99%) 558.5g (4.0mol) in the IP storage tank enters the preheater at a speed of 2.0g / min through the metering pump, and the temperature of the preheater is maintained at 180°C, after the IP temperature at the outlet of the preheater reaches 110°C, it enters the fixed bed reactor from the upper feed port of the fixed bed, then starts the liquid hydrocyanic acid metering pump, and 54.6g of liquid hydrocyanic acid in the storage tank ( 99%, 2.0 mol) is injected into the fixed bed reactor from the feeding port at the upper 1 / 5 of the fixed bed at a speed of 0.2 g / min. IP and hydrocyanic acid flow through the fixed bed reactor from top to bottom. The temperature of the fixed bed reactor is control...

Embodiment 2

[0034]Put 400ml of strong basic exchange resin IRA-900 (agent of Shanghai Gongshuo Biotechnology Co., Ltd.) into a cylindrical fixed-bed reactor with a length of 800mm and a diameter of 25mm for subsequent use. Turn on the preheater and the heat tracing of the fixed bed jacket, the raw material IP (99%) 558.5g (4.0mol) in the IP storage tank enters the preheater at a speed of 2.0g / min through the metering pump, and the temperature of the preheater is maintained at 180°C, after the IP temperature at the outlet of the preheater reaches 110°C, it enters the fixed bed reactor from the upper feed port of the fixed bed, then starts the liquid hydrocyanic acid metering pump, and 54.6g of liquid hydrocyanic acid in the storage tank ( 99%, 2.0 mol) is injected into the fixed bed reactor from the feeding port at the upper 1 / 5 of the fixed bed at a speed of 0.3 g / min. IP and hydrocyanic acid flow through the fixed bed reactor from top to bottom. The temperature of the fixed bed reactor ...

Embodiment 3

[0036] Put 400ml of strong basic exchange resin IRA-401 (strong basic type II resin, agent of Shanghai Boyao Biotechnology Co., Ltd.) into a cylindrical fixed-bed reactor with a length of 800 mm and a diameter of 25 mm for standby. Turn on the preheater and the heat tracing of the fixed bed jacket, the raw material IP (99%) 558.5g (4.0mol) in the IP storage tank enters the preheater at a speed of 2.0g / min through the metering pump, and the temperature of the preheater is maintained at 180°C, after the IP temperature at the outlet of the preheater reaches 120°C, it enters the fixed bed reactor from the upper feed port of the fixed bed, then starts the liquid hydrocyanic acid metering pump, and 54.6g of liquid hydrocyanic acid in the storage tank ( 99%, 2.0 mol) is injected into the fixed bed reactor from the feeding port at the upper 1 / 5 of the fixed bed at a speed of 0.25 g / min. IP and hydrocyanic acid flow through the fixed bed reactor from top to bottom. The temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com