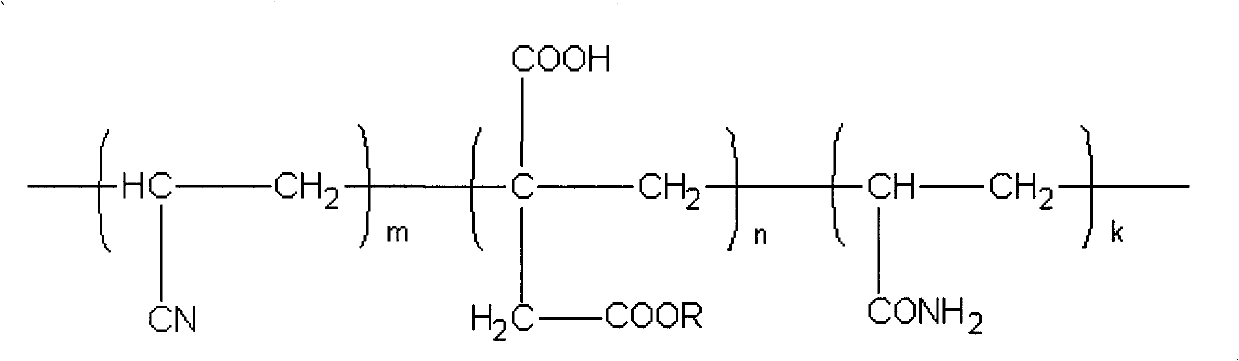

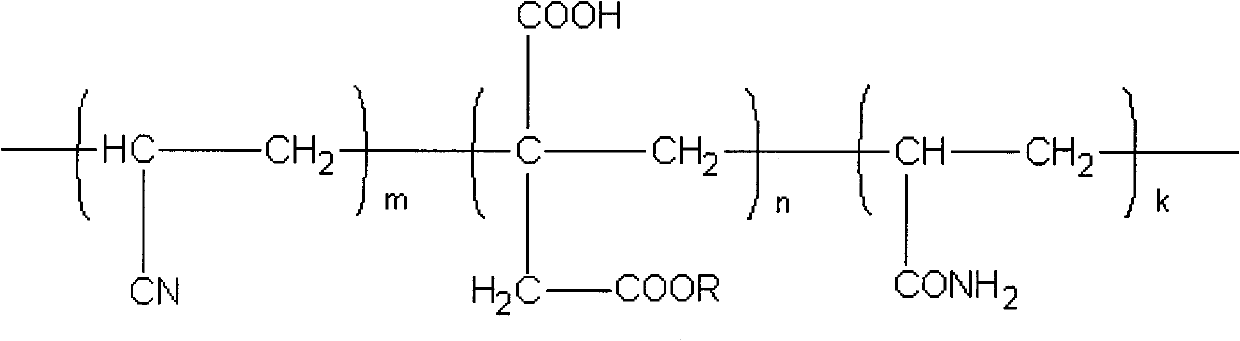

High molecular weight acrylonitrile terpolymer and preparation method thereof

A technology of acrylonitrile copolymer and acrylonitrile, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc. It can solve the problems of narrow exothermic peak width, wide molecular weight distribution, and inability to solve exothermic peaks, and achieve high molecular weight and narrow molecular weight distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh dimethyl sulfoxide, acrylonitrile, acrylamide, β-butyl itaconate, and azobisisoheptanonitrile at a weight ratio of 800:196:1.5:2.5:1, and replace with nitrogen three times at room temperature, Polymerize at 35°C for 24 hours, remove residual monomers and air bubbles under vacuum to obtain acrylonitrile / acrylamide / β-butyl itaconate terpolymer, which is confirmed to be the ternary structure by infrared spectroscopy and elemental analysis, m= 2778, n=30, k=50; the weight average molecular weight of the copolymer is 258,000, and the molecular weight distribution index is 1.72. Thermal analysis DSC shows exothermic onset temperature T 1 =215°C, exothermic end temperature T 2 =308°C, ΔT=T 2 -T 1 =93°C, with a broad exothermic peak.

Embodiment 2

[0019] Weigh dimethyl sulfoxide, acrylonitrile, acrylamide, β-butyl itaconate, and azobisisoheptanonitrile at a weight ratio of 800:196:3:1:1, and replace them with nitrogen four times at room temperature , polymerized at 40°C for 24 hours, vacuum removed residual monomers and air bubbles, and obtained acrylonitrile / acrylamide / β-butyl itaconate terpolymer, which was confirmed by infrared spectroscopy and elemental analysis to be the ternary structure, copolymerization The weight average molecular weight is 182,000, m=1995, n=75, k=25 and the molecular weight distribution index is 1.69. Thermal analysis DSC shows exothermic onset temperature T 1 =214℃, exothermic end temperature T 2 =304°C, ΔT=T 2 -T 1 = 90°C.

Embodiment 3

[0021] Weigh dimethyl sulfoxide, acrylonitrile, acrylamide, β-ethyl itaconate, and azobisisoheptanonitrile at a weight ratio of 800:196:2:2:1, and replace them with nitrogen five times at room temperature , polymerized at 50°C for 24 hours, vacuum removed residual monomers and air bubbles, and obtained acrylonitrile / acrylamide / β-ethyl itaconate terpolymer, which was confirmed by infrared spectroscopy and elemental analysis to be the ternary structure, m =1556, n=25, k=25 The weight average molecular weight of the copolymer is 156,000, and the molecular weight distribution index is 1.87. Thermal analysis DSC shows exothermic onset temperature T 1 =212°C, exothermic end temperature T 2 =306°C, ΔT=T 2 -T 1 = 94°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com